Aug . 07, 2024 20:35 Back to list

Quality Steel Welded Wire Mesh Solutions from Leading Manufacturers for Various Applications

The Evolution and Importance of Steel Welded Wire Mesh Manufacturers

In the realm of construction and industrial applications, steel welded wire mesh plays a pivotal role in providing structural integrity and reinforcement. As the demand for durable and efficient building materials grows, steel welded wire mesh manufacturers are at the forefront of innovation and quality.

What is Steel Welded Wire Mesh?

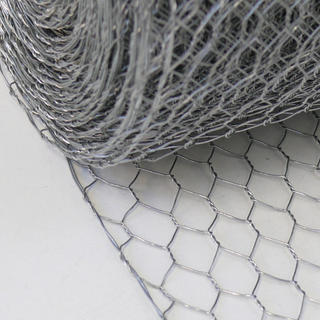

Steel welded wire mesh is a grid-like structure made from interwoven steel wires that are welded at their intersections. This type of mesh is available in various sizes and gauges, providing flexibility for a range of applications from simple concrete reinforcement to more complex solutions in agricultural and fencing industries. The manufacturing process involves drawing steel wires to the desired diameter, arranging them in a grid layout, and employing high-temperature welding techniques to bond them together, resulting in a robust yet flexible mesh.

Applications of Steel Welded Wire Mesh

Steel welded wire mesh is celebrated for its versatility, finding applications in several fields

1. Construction It is predominantly used in concrete reinforcement, ensuring that structures like bridges, buildings, and pavements can withstand tensile and compressive forces.

2. Agriculture Farmers utilize welded wire mesh in fencing and as support for crops, especially climbing plants. Its durability ensures long-lasting solutions for protecting livestock and crops.

3. Industrial Uses In factories and warehouses, welded wire mesh is used for security fencing, machine guarding, and storage solutions. Its strength provides peace of mind in hazardous environments.

steel welded wire mesh manufacturer

The Role of Manufacturers

Steel welded wire mesh manufacturers are integral to ensuring a steady supply of high-quality products. They are equipped with advanced machinery capable of producing custom sizes and specifications to meet industry needs. Quality control is paramount; therefore, manufacturers perform rigorous testing on raw materials and finished products to ensure they meet international standards.

Furthermore, these manufacturers are continually innovating to adapt to changing market demands and environmental considerations. Sustainable practices, such as recycling scrap metal and using eco-friendly coatings, have become essential components of modern manufacturing processes.

Challenges Faced by Manufacturers

Despite their pivotal role, steel welded wire mesh manufacturers face a plethora of challenges. The fluctuating prices of raw materials, particularly steel, can significantly impact production costs. Additionally, the industry is grappling with increasing competition from low-cost manufacturers, which can compromise quality.

Moreover, as construction practices evolve, manufacturers must stay ahead by investing in technological advancements and training for their workforce. Continuous improvement in product quality and manufacturing efficiency is essential to maintain a competitive edge.

Future Directions

The future of the steel welded wire mesh industry appears promising. With the rise of smart construction technologies and sustainable building practices, the demand for high-quality welded wire mesh is set to increase. Manufacturers are likely to explore innovative materials and production methods, such as incorporating smart sensors into mesh products for monitoring structural integrity.

As cities grow and infrastructure demands escalate, the role of steel welded wire mesh will continue to be vital in creating safe, strong, and sustainable environments. By focusing on quality, sustainability, and innovation, steel welded wire mesh manufacturers will undoubtedly remain key players in the construction and industrial sectors for years to come.

In conclusion, the significance of steel welded wire mesh manufacturers cannot be overstated. They not only provide essential materials for a variety of applications but also contribute to the ongoing evolution of construction standards and practices. With the right focus and investment, the future of this industry looks bright.

-

12mm Stainless Steel Wire Mesh for Industrial & Commercial Use Top Quality Factories & Manufacturers

NewsJun.24,2025

-

Black Annealed Wire Specification - High Quality & Custom Options from Leading Factories, Suppliers, Manufacturers

NewsJun.10,2025

-

High-Quality 18 Gauge Black Steel Wire Reliable Factories & Suppliers

NewsJun.10,2025

-

Chain Link Fence Gates - Durable & Secure Access Solutions

NewsJun.10,2025

-

Premium Cold Rolled Steel Bar Supplier High Strength & Precision

NewsJun.10,2025

-

Galvanized Wire Brick Force Mesh - Corrosion Resistant

NewsJun.09,2025