Jul . 26, 2024 13:16 Back to list

Quality SL82 Reinforcing Mesh Production Facility for Durable Construction Solutions and Structural Integrity

The Role and Importance of SL82% Reinforcing Mesh in Construction

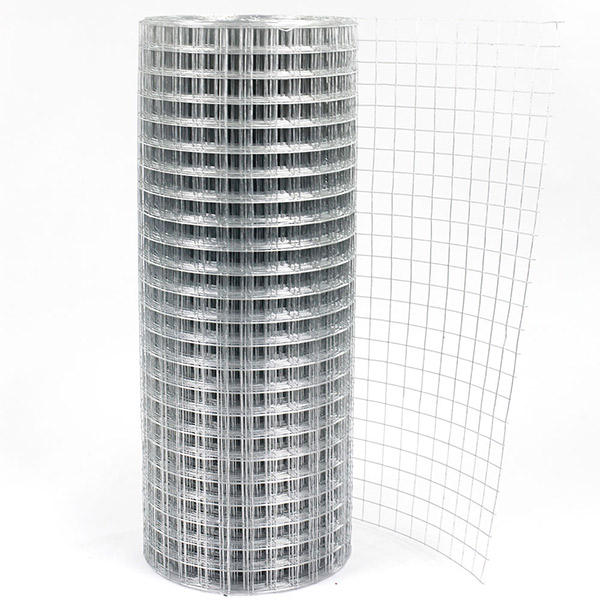

In the realm of construction and civil engineering, the materials used play a pivotal role in ensuring the structural integrity and longevity of buildings and infrastructure. One such essential material is the SL82% reinforcing mesh. This steel mesh, composed of high-quality welded wires, is widely utilized for reinforcing concrete structures, providing strength, durability, and stability to various construction projects.

Understanding SL82% Reinforcing Mesh

SL82% reinforcing mesh typically consists of steel wires arranged in a grid pattern, with spacings that help distribute loads across the concrete surface. The designation SL82% refers to the specific configuration of the mesh, where the “SL” stands for steel lattice and “82” signifies the wire diameter and spacing. This particular type of mesh is designed to cater to various applications, including flooring, walls, and pavements, making it a versatile choice for builders and contractors.

Key Benefits of SL82% Reinforcing Mesh

One of the primary benefits of using SL82% reinforcing mesh is its ability to enhance the tensile strength of concrete. Concrete, while strong under compression, is weak when subjected to tensile forces. The incorporation of reinforcing mesh helps mitigate this weakness by providing support and distributing stresses evenly throughout the structure.

Additionally, using SL82% mesh can lead to significant cost savings during construction. By reducing the amount of concrete required and minimizing the risk of cracking and structural failure, this mesh not only accelerates the construction process but also lowers long-term maintenance costs. Moreover, its lightweight characteristic simplifies handling and installation, enabling construction teams to work more efficiently.

Applications in the Construction Industry

sl82 reinforcing mesh factory

SL82% reinforcing mesh finds its utility across various sectors within the construction industry. In residential building projects, it is commonly employed in floor slabs and driveways, optimizing load distribution and enhancing durability. In larger infrastructure projects, such as bridges and roads, the mesh plays a critical role in reinforcing these structures to withstand dynamic loads and environmental stresses.

Furthermore, the use of SL82% mesh is crucial in areas prone to seismic activity. By providing additional support in critical areas, it aids in the overall resilience of structures against earthquakes, thereby ensuring safety for occupants.

Manufacturing Quality and Standards

The production of SL82% reinforcing mesh must adhere to strict industry standards to ensure quality and performance. Reputable manufacturers employ advanced welding techniques and high-grade materials to produce mesh that meets or exceeds international standards. This commitment to quality ensures that builders can rely on the performance of the mesh, reducing the likelihood of issues during the lifetime of the structure.

In addition, many manufacturers of SL82% reinforcing mesh emphasize sustainable practices in their production processes. By utilizing recycled materials and implementing energy-efficient manufacturing processes, they contribute to the broader goal of sustainability within the construction industry.

Conclusion

In summary, SL82% reinforcing mesh is an indispensable component in modern construction practices. Its ability to enhance the tensile strength of concrete while providing economic benefits makes it a preferred choice for builders and engineers alike. As construction methods evolve and the demand for durable infrastructure grows, the importance of high-quality reinforcing materials like SL82% mesh will only continue to increase. Through innovative manufacturing and adherence to rigorous standards, the future of SL82% reinforcing mesh looks promising, solidifying its role within the construction landscape for years to come.

-

High Quality Deformed Steel Bars China - Reliable Manufacturers & Suppliers for Construction Projects

NewsJul.08,2025

-

High Quality Black Annealed Wire - Durable Iron Wire 2mm from Leading Manufacturer & Supplier Factory

NewsJul.08,2025

-

Produce Hot Dipped Galvanized Steel Grating - High Quality Grating Supplier & Manufacturer

NewsJul.08,2025

-

Galvanized Iron Welded Wire Mesh Panels – Durable, Rust-Resistant, Best Price Manufacturer

NewsJul.07,2025

-

High Quality Concrete Reinforcing Welded Wire Mesh - Durable 8mm Steel Bar, Q188, A393, F72, High Strength Mesh Solutions

NewsJul.07,2025

-

High-Quality Redrawn G.I. Wire Leading Manufacturers & Suppliers

NewsJul.07,2025