Oct . 19, 2024 19:11 Back to list

pvc coated wire

Understanding PVC Coated Wire An Overview

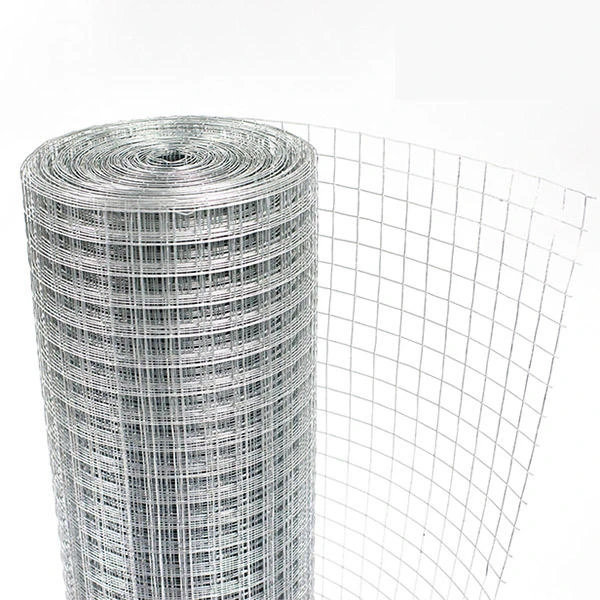

PVC coated wire has become increasingly popular across various industries due to its versatility, durability, and a range of protective qualities. Essentially, this type of wire is composed of a core metal, usually steel or iron, that is covered with a layer of polyvinyl chloride (PVC). This coating not only enhances the wire's resistance to corrosion and rust but also improves its aesthetic appeal and safety during handling.

Properties and Benefits

One of the foremost benefits of PVC coated wire is its exceptional resistance to environmental factors. The PVC coating acts as a barrier against moisture, chemicals, and extreme temperatures, making it suitable for both indoor and outdoor applications. This makes the wire particularly valuable in settings that demand robust materials, such as construction sites, agricultural environments, and even in the manufacturing of outdoor furniture.

The versatility of PVC coated wire is another significant advantage. It comes in various colors, allowing for easy integration into design schemes while also providing a degree of visibility which can be crucial for safety. The vibrant colors can be advantageous in fencing applications, as they can enhance the visibility of boundaries and reduce the risk of accidents.

In addition to its durability and aesthetic options, PVC coated wire also provides a significant safety advantage. The soft, pliable coating reduces the likelihood of cuts and abrasions, making it easier to handle and install. This is particularly relevant in industries such as construction and landscaping, where workers frequently come into contact with various materials.

Applications of PVC Coated Wire

pvc coated wire

The applications for PVC coated wire are extensive and varied. One of its most common uses is in fencing. Garden and agricultural fences made from PVC coated wire are not only resilient but can also blend seamlessly into natural landscapes, thanks to the range of available colors. Additionally, the coating helps to prevent rusting, ultimately extending the lifespan of the fencing.

Another application is in the manufacturing of wire products. Items such as wire racks, displays, and furniture benefit from the use of PVC coated wire due to its durability and finish. This wire is often preferred in the production of indoor products because it provides an appealing look while also ensuring strength and stability.

Moreover, PVC coated wire is used in a variety of industrial applications, including creating wire harnesses and connectors that require insulation from moisture and chemicals. The electrical industry values PVC coated wire for these attributes, as it helps maintain the integrity of electrical systems and prevents failures resulting from environmental exposure.

Conclusion

In conclusion, PVC coated wire is an excellent choice for those seeking a combination of durability, safety, and aesthetic appeal in various applications. Its resistance to environmental factors, coupled with its versatility in application and handling, makes it a go-to material in many industries. As technology advances, the formulations and applications of PVC coated wire are likely to evolve, further solidifying its role as an indispensable asset in modern infrastructure, agriculture, and manufacturing.

Whether used for fencing, crafting furniture, or in electrical applications, PVC coated wire stands out as a superior option that meets the demands of today’s environments and industries. Its resilience, safety features, and attractive finish ensure that PVC coated wire remains a material of choice for countless applications.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025