Dec . 03, 2024 21:53 Back to list

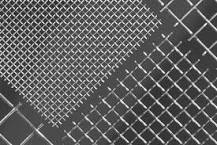

PVC Coated Welded Wire Mesh Panels Manufacturing and Supply Solutions

The Growing Demand for PVC Coated Welded Wire Mesh Panels An Industry Perspective

In recent years, the construction and agricultural industries have seen a significant increase in the demand for durable and versatile fencing solutions. Among these, PVC coated welded wire mesh panels have emerged as a top choice due to their strength, aesthetic appeal, and resistance to corrosion. Factory production of these panels has become essential to meet the expanding needs of various sectors.

PVC coated welded wire mesh panels are constructed from high-quality steel wires that are welded together to form a stable mesh pattern. After welding, the panels are coated with PVC (polyvinyl chloride) to provide an additional layer of protection against environmental factors such as moisture, UV rays, and physical abrasion. This coating not only enhances the panel's longevity but also improves its appearance, making it suitable for both industrial and residential applications.

Versatility in Applications

One of the primary reasons for the rising popularity of PVC coated welded wire mesh panels is their versatility. These panels are widely used in a variety of applications, including

1. Fencing The durability and aesthetic appeal of PVC coated panels make them ideal for fencing in residential properties, parks, and commercial areas. They provide a robust barrier while maintaining a visually pleasing appearance.

2. Agricultural Use Farmers increasingly utilize these mesh panels for livestock enclosures and crop protection. The corrosion-resistant properties help preserve the integrity of the fence in various weather conditions, ensuring reliable containment of animals and protection of crops.

pvc coated welded wire mesh panels factories

3. Industrial Applications In industrial settings, PVC coated welded wire mesh panels are used for security fencing around warehouses and factories. Their high strength and resilience make them an effective deterrent against unauthorized access.

4. Architectural Applications The aesthetic characteristics of PVC coated panels allow them to be used in architectural designs, such as decorative fencing or as infill for railings in balconies, ensuring both safety and style.

Manufacturing Process and Innovations

The production of PVC coated welded wire mesh panels begins with high-grade steel wires, which are expertly welded to form the desired mesh configuration. Following the welding process, the panels undergo a thorough cleaning and galvanization procedure to eliminate impurities and enhance corrosion resistance. Finally, a layer of PVC is applied, either through dipping or spraying techniques, which ensures uniform coverage and adhesion.

Recent innovations in the manufacturing process have further enhanced the quality and efficiency of PVC coated welded wire mesh panels. Advanced machinery and techniques have reduced production time while maintaining strict quality control standards. Additionally, factories are increasingly adopting sustainable practices, such as recycling materials and utilizing eco-friendly production methods, to minimize environmental impact.

Conclusion

The market for PVC coated welded wire mesh panels continues to grow, driven by the increasing need for reliable and visually appealing fencing solutions across various sectors. As factories enhance their production techniques and focus on quality and sustainability, we can expect to see further innovations in this field. This evolution not only meets the demand for stronger and more durable fencing options but also contributes to a more sustainable and responsible approach to manufacturing. Ultimately, PVC coated welded wire mesh panels represent a smart investment for those seeking lasting value in their fencing solutions.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025