Sep . 01, 2024 06:14 Back to list

PVC Coated Wire Factory - High-Quality PVC Coated Wire Manufacturer

PVC Coated Wire Factory Revolutionizing Wire Durability and Versatility

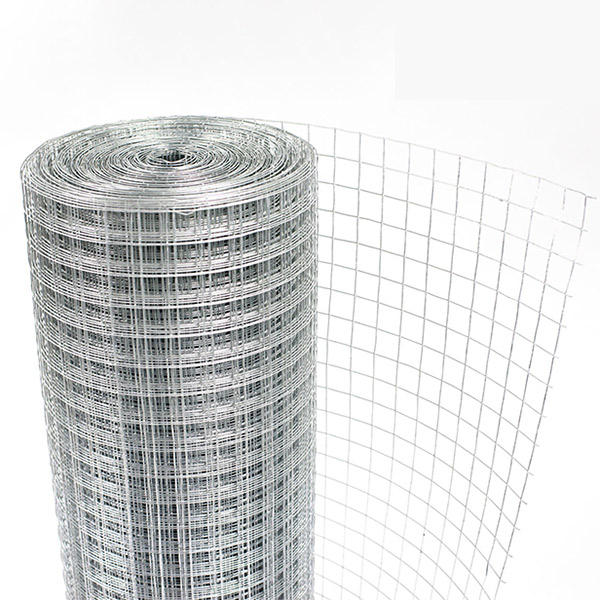

In the modern industrial landscape, the demand for reliable and durable materials has led to innovative advancements in manufacturing processes. Among these innovations is the production of PVC coated wire, a product that has transformed various industries by providing enhanced durability, corrosion resistance, and versatility. PVC coated wire is a type of wire that is coated with polyvinyl chloride (PVC), a synthetic plastic polymer known for its strength and resilience.

A PVC coated wire factory specializes in the production of this highly versatile material, catering to a wide range of applications including construction, agriculture, and fencing. The process of creating PVC coated wire involves first drawing metal wire to the desired thickness. This metal wire is typically made from materials like steel or iron, selected for their strength and suitability for various applications.

PVC Coated Wire Factory Revolutionizing Wire Durability and Versatility

The next step involves the application of the PVC coating. This can be achieved through several methods, including extrusion and dipping. In the extrusion method, the cleaned and pre-treated wire is passed through a heated chamber where PVC pellets are melted and then forced around the wire, forming a tight and even coating. Alternatively, in the dipping process, the wire is immersed in a vat of liquid PVC, allowing the coating to naturally adhere as it cools down.

pvc coated wire factory

One of the primary advantages of PVC coated wire is its exceptional resistance to corrosion and weathering. This makes it ideal for outdoor applications, such as garden fencing, where exposure to moisture and varying temperatures can lead to deterioration of conventional wire. Additionally, the PVC coating provides a smooth surface which not only enhances aesthetic appeal but also reduces the risk of injury from sharp edges.

The versatility of PVC coated wire extends to its wide range of color options. Factories often offer customizable colors, allowing customers to select wire that matches or complements their specific projects. This flexibility has made PVC coated wire a popular choice in landscaping, where visual appeal is a significant consideration.

Moreover, the production of PVC coated wire is not just about meeting current demands but also about adhering to environmental standards. Many PVC coated wire factories are now implementing sustainable practices, such as recycling scrap material and utilizing eco-friendly PVC formulations. These initiatives reflect a growing commitment to reducing the environmental impact associated with manufacturing processes.

In conclusion, the PVC coated wire factory plays a pivotal role in supplying a product that meets the rigorous demands of various industries. With its enhanced durability, corrosion resistance, and aesthetic versatility, PVC coated wire stands out as an essential material in modern construction and landscaping. As technology and environmental awareness continue to evolve, these factories will undoubtedly push the boundaries of innovation, providing even more advanced solutions for their customers. Whether for fencing, agricultural use, or construction purposes, PVC coated wire remains a reliable choice for those seeking quality and performance.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025