Sep . 08, 2024 19:28 Back to list

pvc coated welded wire mesh panels factory

PVC Coated Welded Wire Mesh Panels A Comprehensive Overview of Manufacturing and Applications

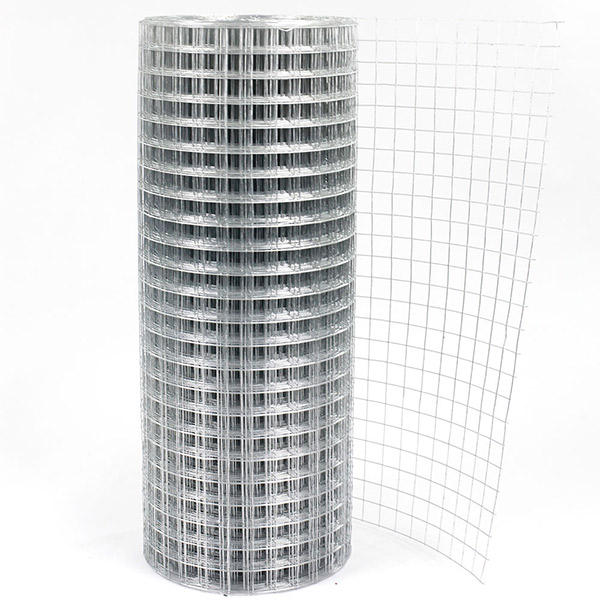

PVC coated welded wire mesh panels are fast becoming a popular choice in various industries due to their versatility, durability, and aesthetic appeal. These panels, engineered from high-quality steel wires, are coated with a layer of polyvinyl chloride (PVC) to enhance their corrosion resistance and extend their lifespan. In this article, we will explore the manufacturing process of these panels, their benefits, and their diverse applications.

Manufacturing Process

The production of PVC coated welded wire mesh panels begins with the careful selection of raw materials. High-tensile steel wires are chosen for their strength and durability. These wires are then welded together at specific intervals to create a series of interconnected grids. The welding process is crucial, as it ensures the structural integrity of the panels.

Once the panels are welded, they undergo a cleaning process to remove any rust, oil, or debris. This step is essential to ensure that the PVC coating adheres properly to the wire mesh surface. Following cleaning, the panels are immersed in a PVC coating solution. This immersion or dipping method guarantees an even and thorough coating, which is then cured to produce a hard, resilient finish. The result is a wire mesh panel that exhibits excellent rust resistance and can withstand the rigors of outdoor use.

Benefits of PVC Coated Welded Wire Mesh Panels

One of the most significant advantages of PVC coated welded wire mesh panels is their resistance to corrosion and weathering. Unlike untreated steel, which can rust over time, the PVC coating protects the underlying metal and allows the panels to maintain their integrity even in harsh environments. This feature makes them ideal for use in fences, animal enclosures, and garden trellises.

Additionally, the panels come in various colors and finishes, allowing for decorative applications without compromising strength. This aesthetic appeal enables designers and architects to incorporate them into residential and commercial landscapes seamlessly.

pvc coated welded wire mesh panels factory

Another notable benefit is their ease of installation. PVC coated welded wire mesh panels are lightweight and can be easily cut or altered to fit specific requirements. This flexibility is particularly beneficial for custom applications, reducing labor costs and installation time.

Diverse Applications

The versatility of PVC coated welded wire mesh panels means that they can be used in a wide range of applications. In agriculture, these panels serve as fencing for livestock and enclosures for crops, protecting them from pests while allowing for proper ventilation and sunlight.

In industrial settings, PVC coated welded wire mesh is utilized for security fencing, storage cages, and even as reinforcing materials for concrete. Their durable nature ensures that they can withstand rigorous handling and environmental exposure.

In residential applications, these panels are favored for decorative fencing, DIY projects, and garden structures. Their ability to complement various landscaping styles makes them a preferred choice among homeowners.

Conclusion

PVC coated welded wire mesh panels represent a blend of functionality and aesthetic appeal. Their manufacturing process ensures high-quality production, while their numerous benefits and applications make them a go-to solution across various sectors. Whether in agriculture, industry, or residential settings, these panels provide durability and versatility, proving to be an invaluable product in the modern marketplace.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025