Jul . 28, 2024 00:35 Back to list

Production and Supply of High-Quality Steel Mesh for Construction Industry Applications

The Importance of Construction Steel Mesh Factories in Modern Construction

In the ever-evolving landscape of construction, the use of steel has become integral to ensuring the durability and stability of structures. Among the various materials utilized, steel mesh plays a pivotal role, especially in reinforcing concrete. The steel mesh acts as a skeleton within concrete, allowing for improved tensile strength and structural integrity. This is where construction steel mesh factories come into play, serving as essential hubs for the production of this vital component.

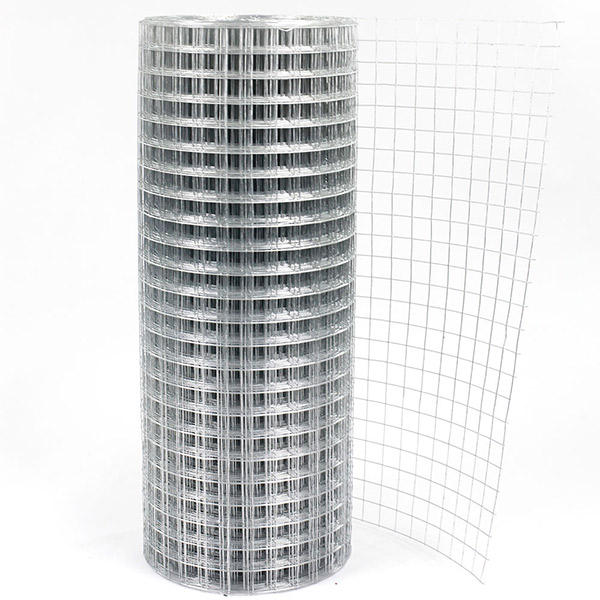

Steel mesh, often made from high-quality low-carbon steel, comes in various forms such as welded wire mesh and expanded metal mesh. These forms are engineered to meet specific construction needs, adapting to different structural demands ranging from residential buildings to towering skyscrapers and bridges. The significance of steel mesh in construction cannot be overstated; it provides the necessary support that concrete alone cannot offer, preventing cracking, reducing shrinkage, and enhancing overall resilience against environmental stresses.

Construction steel mesh factories are specialized facilities dedicated to the production and supply of steel mesh products. The factories utilize advanced technology and machinery to ensure precision and quality in their offerings. The manufacturing process begins with high-grade steel rods, which are cut, shaped, and welded into a specific grid pattern depending on the intended application. This process not only guarantees the uniformity and consistency of the mesh but also enables factories to produce custom sizes catered to specific project requirements.

construction steel mesh factories

One of the key advantages of having dedicated steel mesh factories is the ability to maintain stringent quality control throughout the production process. High-quality steel mesh is crucial for ensuring the safety and longevity of construction projects. By maintaining rigorous standards and using top-tier materials, manufacturers can significantly reduce the risk of structural failures, which can lead to costly repairs and unsafe conditions. Additionally, such factories are equipped to conduct a variety of tests to guarantee that the final product meets industry standards and regulations.

Moreover, the rise of construction steel mesh factories has contributed to the economic landscape by creating jobs and enabling local sourcing of materials. With the construction industry heavily reliant on timely deliveries and cost-effective solutions, having nearby steel mesh suppliers can streamline project timelines and reduce transportation costs. This proximity fosters partnerships between construction firms and manufacturers, paving the way for collaborative innovation and improved efficiency.

As sustainability becomes increasingly important in construction, many factories are now adopting eco-friendly practices in their operations. This includes recycling scrap steel, reducing waste, and implementing energy-efficient manufacturing processes. Such initiatives not only contribute to environmental conservation but also appeal to clients who prioritize sustainable building practices.

In conclusion, construction steel mesh factories are vital to the modern construction industry, providing essential products that enhance the strength and durability of structures. Their role in ensuring safety, promoting local economies, and adopting sustainable practices cannot be understated. As the demand for stronger and more resilient buildings continues to grow, the importance of steel mesh production will undoubtedly increase, solidifying the position of these factories as cornerstones of modern infrastructure development. The future of construction hinges on innovation and the ability to produce high-quality materials efficiently, making these factories crucial players in the journey toward sustainable and robust urban development.

-

High Quality Roll Welded Wire Mesh for Concrete Reinforcing BWG22 Galvanized Mesh Rolls Factory Direct

NewsJul.04,2025

-

High Quality Deformed Steel Bars China - Leading Manufacturers & Suppliers

NewsJul.04,2025

-

12mm Stainless Steel Wire Mesh for Industrial & Commercial Use Top Quality Factories & Manufacturers

NewsJun.24,2025

-

Black Annealed Wire Specification - High Quality & Custom Options from Leading Factories, Suppliers, Manufacturers

NewsJun.10,2025

-

High-Quality 18 Gauge Black Steel Wire Reliable Factories & Suppliers

NewsJun.10,2025

-

Chain Link Fence Gates - Durable & Secure Access Solutions

NewsJun.10,2025