Jun . 12, 2024 23:26 Back to list

Producers of diamond mesh products

The Pioneers of Diamond Mesh Manufacturing Crafting Quality and Innovation

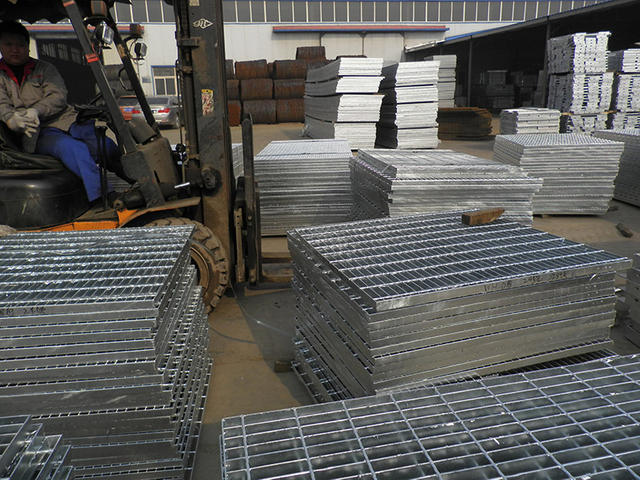

Diamond mesh, a versatile and robust material, has found its way into various industries, from construction to agriculture, due to its unique properties. Its intricate pattern, resembling a diamond lattice, is the result of the skilled craftsmanship and precision engineering of diamond mesh manufacturers worldwide. This article delves into the world of these manufacturers, their processes, and the significance of their products.

Manufacturing diamond mesh involves a meticulous process that starts with selecting high-quality raw materials, typically steel wires. The wires are then woven or welded together to form the distinctive diamond pattern. The choice between weaving and welding depends on the intended application and desired strength of the final product. Weaving is often used for lighter applications, while welding provides enhanced durability for heavy-duty uses.

Leading diamond mesh manufacturers prioritize innovation and technology in their production lines. They utilize state-of-the-art machinery and advanced techniques to ensure consistency, precision, and efficiency. Automated systems minimize human error, while computer-aided design (CAD) enables customization to meet specific customer requirements.

One of the key factors that distinguish diamond mesh manufacturers is their commitment to quality. They adhere to strict international standards, such as ASTM and ISO, to guarantee the durability, tensile strength, and corrosion resistance of their products They adhere to strict international standards, such as ASTM and ISO, to guarantee the durability, tensile strength, and corrosion resistance of their products They adhere to strict international standards, such as ASTM and ISO, to guarantee the durability, tensile strength, and corrosion resistance of their products They adhere to strict international standards, such as ASTM and ISO, to guarantee the durability, tensile strength, and corrosion resistance of their products

They adhere to strict international standards, such as ASTM and ISO, to guarantee the durability, tensile strength, and corrosion resistance of their products They adhere to strict international standards, such as ASTM and ISO, to guarantee the durability, tensile strength, and corrosion resistance of their products diamond mesh manufacturers. Regular quality checks at every stage of production ensure that the finished product meets or exceeds customer expectations.

Beyond the technical aspects, diamond mesh manufacturers also focus on sustainability. Recyclable materials are often used, and efforts are made to minimize waste during production. Many manufacturers have adopted eco-friendly practices, contributing positively to the environment.

The global market for diamond mesh manufacturers is competitive, with companies vying to offer the most innovative solutions. Some have expanded their product range to include galvanized, PVC-coated, or stainless steel meshes, each with its own benefits. Galvanization enhances rust resistance, while PVC coating adds an extra layer of protection against wear and tear.

In conclusion, diamond mesh manufacturers play a vital role in shaping the infrastructure and utilities around us. Their dedication to precision, quality, and innovation has made diamond mesh a go-to material for numerous applications. As technology continues to evolve, it's exciting to envision the new frontiers these manufacturers will explore, further solidifying their position in the global manufacturing landscape.

diamond mesh manufacturers. Regular quality checks at every stage of production ensure that the finished product meets or exceeds customer expectations.

Beyond the technical aspects, diamond mesh manufacturers also focus on sustainability. Recyclable materials are often used, and efforts are made to minimize waste during production. Many manufacturers have adopted eco-friendly practices, contributing positively to the environment.

The global market for diamond mesh manufacturers is competitive, with companies vying to offer the most innovative solutions. Some have expanded their product range to include galvanized, PVC-coated, or stainless steel meshes, each with its own benefits. Galvanization enhances rust resistance, while PVC coating adds an extra layer of protection against wear and tear.

In conclusion, diamond mesh manufacturers play a vital role in shaping the infrastructure and utilities around us. Their dedication to precision, quality, and innovation has made diamond mesh a go-to material for numerous applications. As technology continues to evolve, it's exciting to envision the new frontiers these manufacturers will explore, further solidifying their position in the global manufacturing landscape.

They adhere to strict international standards, such as ASTM and ISO, to guarantee the durability, tensile strength, and corrosion resistance of their products They adhere to strict international standards, such as ASTM and ISO, to guarantee the durability, tensile strength, and corrosion resistance of their products

They adhere to strict international standards, such as ASTM and ISO, to guarantee the durability, tensile strength, and corrosion resistance of their products They adhere to strict international standards, such as ASTM and ISO, to guarantee the durability, tensile strength, and corrosion resistance of their products diamond mesh manufacturers. Regular quality checks at every stage of production ensure that the finished product meets or exceeds customer expectations.

Beyond the technical aspects, diamond mesh manufacturers also focus on sustainability. Recyclable materials are often used, and efforts are made to minimize waste during production. Many manufacturers have adopted eco-friendly practices, contributing positively to the environment.

The global market for diamond mesh manufacturers is competitive, with companies vying to offer the most innovative solutions. Some have expanded their product range to include galvanized, PVC-coated, or stainless steel meshes, each with its own benefits. Galvanization enhances rust resistance, while PVC coating adds an extra layer of protection against wear and tear.

In conclusion, diamond mesh manufacturers play a vital role in shaping the infrastructure and utilities around us. Their dedication to precision, quality, and innovation has made diamond mesh a go-to material for numerous applications. As technology continues to evolve, it's exciting to envision the new frontiers these manufacturers will explore, further solidifying their position in the global manufacturing landscape.

diamond mesh manufacturers. Regular quality checks at every stage of production ensure that the finished product meets or exceeds customer expectations.

Beyond the technical aspects, diamond mesh manufacturers also focus on sustainability. Recyclable materials are often used, and efforts are made to minimize waste during production. Many manufacturers have adopted eco-friendly practices, contributing positively to the environment.

The global market for diamond mesh manufacturers is competitive, with companies vying to offer the most innovative solutions. Some have expanded their product range to include galvanized, PVC-coated, or stainless steel meshes, each with its own benefits. Galvanization enhances rust resistance, while PVC coating adds an extra layer of protection against wear and tear.

In conclusion, diamond mesh manufacturers play a vital role in shaping the infrastructure and utilities around us. Their dedication to precision, quality, and innovation has made diamond mesh a go-to material for numerous applications. As technology continues to evolve, it's exciting to envision the new frontiers these manufacturers will explore, further solidifying their position in the global manufacturing landscape. Latest news

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Co., Ltd.|Durable Security&Versatile Applications

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen|Heat-Resistant & BPA Free

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd|Eco-friendly Durable Storage

NewsAug.18,2025

-

Welded Wire Mesh for Industry | Factory Direct Supplies

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co.,Ltd|Eco-Friendly, Heat-Resistant, Durable

NewsAug.17,2025