Dec . 05, 2024 14:01 Back to list

Perforated Metal Sheet Manufacturer with Custom Design and High Quality Production

The Significance of Perforated Metal Sheets and Their Manufacturing Process

Perforated metal sheets are an essential component in various industries due to their versatility and functional benefits. These sheets, characterized by their strategic holes or patterns, serve a wide array of purposes such as filtration, ventilation, security, and aesthetic design. The expanding applications of perforated metal sheets have led to the rise of dedicated factories focusing on efficient production methods, innovative designs, and high-quality materials.

Understanding Perforated Metal Sheets

At its core, a perforated metal sheet is a piece of metal that has been mechanically punched or drilled to create a series of holes or patterns. This form of metal is commonly made from materials such as stainless steel, aluminum, brass, and carbon steel. The size, shape, and spacing of the holes can be customized to suit specific applications, making perforated sheets highly adaptable.

One of the most appealing characteristics of perforated metal sheets is their ability to combine strength with lightweight properties. They provide structural integrity while allowing for airflow, light penetration, and sound attenuation. Due to these qualities, they find applications in sectors ranging from construction and architecture to manufacturing and agriculture.

The Manufacturing Process

The manufacturing of perforated metal sheets involves several crucial steps, beginning with the selection of the base material. Factories typically source high-quality metals that ensure durability and longevity. After determining the required specifications, the metal sheets are cut to size.

The manufacturing process generally employs advanced machinery, such as CNC (Computer Numerical Control) punching machines or laser cutting equipment. These machines can create a variety of hole patterns with precision and speed, drastically reducing production time and increasing efficiency.

perforated metal sheet factory

After the punching or cutting process, the perforated sheets undergo finishing treatments. These can include deburring to remove sharp edges, surface treatments such as galvanization or powder coating for corrosion resistance, and cleaning to ensure the final product meets industry standards. Quality control is vital during this stage; manufacturers conduct inspections to ensure that the sheets adhere to specified tolerances and maintain the integrity of the perforations.

Applications Across Industries

The range of applications for perforated metal sheets is broad and varied. In the architectural sector, they are often used in façades, sunshades, and decorative elements, contributing both functionality and visual appeal to buildings. In industrial settings, perforated sheets are crucial for filtration systems, acoustic panels, and safety guards.

Furthermore, in the automotive industry, they are used in heat exchangers and louvers, while in the food and beverage sector, perforated metal sheets help in sifting and filtering processes. Even in home decor, artists and designers utilize perforated sheets for innovative projects such as lighting fixtures and art installations.

Conclusion

As industries continue to evolve and expand, the demand for high-quality, customizable perforated metal sheets remains strong. Factories dedicated to their production play a pivotal role in meeting this demand by investing in state-of-the-art equipment and skilled workforce. By offering versatile products that combine functionality with aesthetic value, perforated metal sheet manufacturers contribute significantly to the development and innovation across various fields.

In summary, the significance of perforated metal sheets lies not only in their diverse application possibilities but also in the sophisticated manufacturing processes that bring them to life. The continuous advancements in technology and manufacturing techniques ensure that these sheets will remain an integral part of modern industry for years to come.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

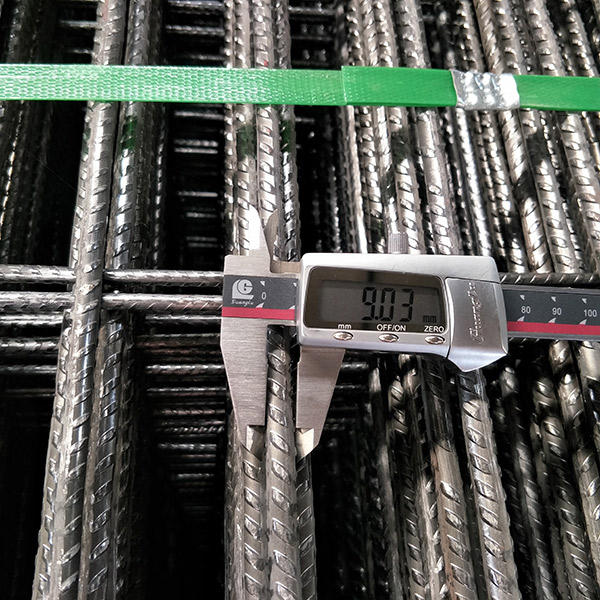

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025