Nov . 08, 2024 02:29 Back to list

Custom Welded Wire Mesh Panels for OEM Applications and Industrial Solutions

Understanding OEM Wire Panel Welded Wire Mesh

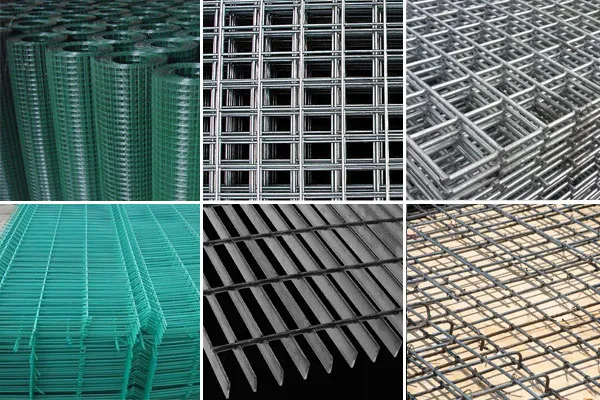

In the world of industrial applications, welded wire mesh is an essential construction material that serves a multitude of purposes. Among its diverse applications, OEM (Original Equipment Manufacturer) wire panel welded wire mesh has carved out a unique niche. This article delves into the characteristics, manufacturing process, applications, and benefits of OEM wire panel welded wire mesh.

Characteristics

OEM wire panel welded wire mesh is constructed from high-quality steel wire that is welded at the intersections, providing superior strength and durability. The panels are available in various sizes and designs to meet specific needs. The wire gauges used can vary, allowing for fine-tuning of the mesh’s strength and flexibility. The surface of the wire panel is often treated for corrosion resistance, enhancing its longevity in various environments.

A crucial feature of OEM wire panel mesh is its versatility. It can be manufactured in different mesh sizes and spacing to cater to distinct applications, from agricultural needs to security fencing. The welded intersections create a robust structure that doesn’t just provide support but also controls the spacing effectively, ensuring that the mesh retains its shape over time.

Manufacturing Process

The process of creating OEM wire panel welded wire mesh begins with selecting high-grade raw materials. Typically, low carbon steel wires are used due to their weldability and strength. The wires are cut to the desired length and then arranged on a grid to form the panels.

The critical step in the manufacturing process is the welding. Advanced machinery, including automatic welding machines, is employed to fuse the wires at their intersections, creating a solid structure. The welded panels are then subjected to quality control measures to ensure they meet industry standards. Post-weld, finishes such as galvanization or PVC coating can be applied to enhance corrosion resistance and aesthetic appeal.

oem wire panel welded wire mesh

Applications

OEM wire panel welded wire mesh has a wide array of applications across different industries. In agriculture, it is used for livestock enclosures, ensuring the safety of animals while allowing for visibility and air circulation. The mesh can also be utilized in the construction industry as reinforcement for concrete slabs, walls, and foundations, providing enhanced stability and strength.

In security applications, OEM welded wire panels are used in fencing systems, barriers, and protective screens, providing a formidable defense against intrusion and vandalism. Similarly, they find their place in infrastructure projects, serving as safety barriers on roads, highways, and construction sites.

Further, in the realm of home improvement, these panels can be used for garden fencing, trellises, and protective grilles for windows and doors. Their aesthetic flexibility allows homeowners to choose designs that blend seamlessly with their property’s style.

Benefits

The adoption of OEM wire panel welded wire mesh presents numerous benefits. First and foremost, its durability means that it can withstand harsh environmental conditions, making it a cost-effective solution over time. The welded construction minimizes the risk of gaps and irregularities, ensuring a reliable and uniform performance.

Moreover, the ease of installation cannot be overstated. OEM wire panels can be quickly and efficiently set up, resulting in reduced labor costs and project timelines. Their aesthetic appeal, particularly when finished with coatings, makes them an excellent choice for both industrial and residential applications.

In conclusion, OEM wire panel welded wire mesh stands as a testament to innovation in material science, combining strength, versatility, and aesthetic appeal. Its applications are as diverse as its advantages, making it an invaluable asset across various sectors. Whether for agricultural use, security solutions, or construction reinforcement, OEM welded wire mesh is a prime example of how a humble material can deliver robust performance and satisfy modern needs.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025