Dec . 10, 2024 12:29 Back to list

oem weld wire mesh

The Importance of OEM Weld Wire Mesh in Modern Manufacturing

In today's fast-paced manufacturing landscape, the demand for high-quality materials is paramount. One such material that has gained traction for its versatility and strength is OEM weld wire mesh. This product is increasingly being utilized across various industries due to its significant advantages in terms of durability, customization, and cost-effectiveness.

What is OEM Weld Wire Mesh?

OEM stands for Original Equipment Manufacturer, referring to companies that produce products for other brands to sell under their labels. Weld wire mesh is a grid-like structure made from metal wires that are welded together at each intersection. This method of manufacturing results in a robust product capable of withstanding high-pressure environments and providing structural integrity.

Versatility Across Industries

One of the standout features of OEM weld wire mesh is its versatility. It can be used in numerous applications across various sectors including construction, agriculture, automotive, and even aerospace. For example, in construction, weld mesh is often utilized for reinforcement in concrete, providing a solid framework that enhances the strength of structures. In agriculture, it serves as fencing material, livestock enclosures, and even as a support for crops.

In the automotive sector, OEM weld wire mesh is utilized for creating safety barriers and components that require both light weight and strength. The aerospace industry also benefits from this mesh, using it in delicate applications where precision and durability are crucial.

Customization Options

oem weld wire mesh

Another significant advantage of OEM weld wire mesh is the ability to customize it according to specific client requirements. Manufacturers often provide a range of wire diameters, mesh openings, and material types, ensuring that businesses can procure a product that perfectly suits their application. This customization not only supports better performance but also aids in meeting industry regulations and standards.

Choosing the right mesh can significantly impact the efficiency of a project. For instance, different mesh sizes can dictate air flow, visibility, and load-bearing capacities, all of which need to be considered during the planning phase.

Cost-Effectiveness and Longevity

Investing in OEM weld wire mesh can also result in long-term savings. While the initial cost might appear higher than traditional fencing or mesh products, the durability and strength of OEM weld wire mesh mean that it has a longer life cycle. It resists rust, corrosion, and wear, minimizing the need for frequent replacements. This longevity not only reduces material costs over time, but it also lowers labor costs associated with installation and maintenance.

Quality Assurance and Standards

When sourcing OEM weld wire mesh, quality assurance is a crucial factor. Reliable manufacturers adhere to strict industry standards to ensure that their products are safe and effective for various applications. This adherence to quality can provide peace of mind for businesses that depend on the performance of these materials in their operations.

Conclusion

In conclusion, OEM weld wire mesh is an indispensable material in the modern manufacturing industry. Its unmatched versatility, customizability, and cost-effectiveness make it a preferred choice across various sectors. As industries continue to evolve and adapt, investing in high-quality weld wire mesh will likely remain a strategic decision for businesses looking to enhance operational efficiency and product longevity. By partnering with reputable OEM manufacturers, companies can secure the supplies needed to drive innovation and success in their respective fields.

-

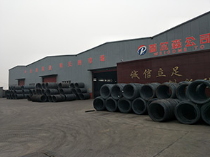

Welded Wire Mesh for Industry Factory - Anping County Puersen Hardware Wire Mesh Co., Ltd.|Durability, Corrosion Resistance, Customization

NewsSep.01,2025

-

welded wire mesh - Anping County Puersen Hardware Wire Mesh Products Co., Ltd | Construction, Industrial Applications

NewsSep.01,2025

-

Welded Wire Mesh for Industry Factory - Anping County Puersen Hardware Wire Mesh Products Co., Ltd.|Corrosion Resistance&Structural Integrity

NewsSep.01,2025

-

Welded Wire Mesh for Industry Factory - Anping County Puersen Hardware Wire Mesh Products Co., Ltd.

NewsAug.29,2025

-

Welded Wire Mesh for Industry Factory | Durable & Cost-Effective Solutions

NewsAug.29,2025

-

Durable Welded Wire Mesh for Industry Factory | Custom Solutions

NewsAug.27,2025