Dec . 10, 2024 04:56 Back to list

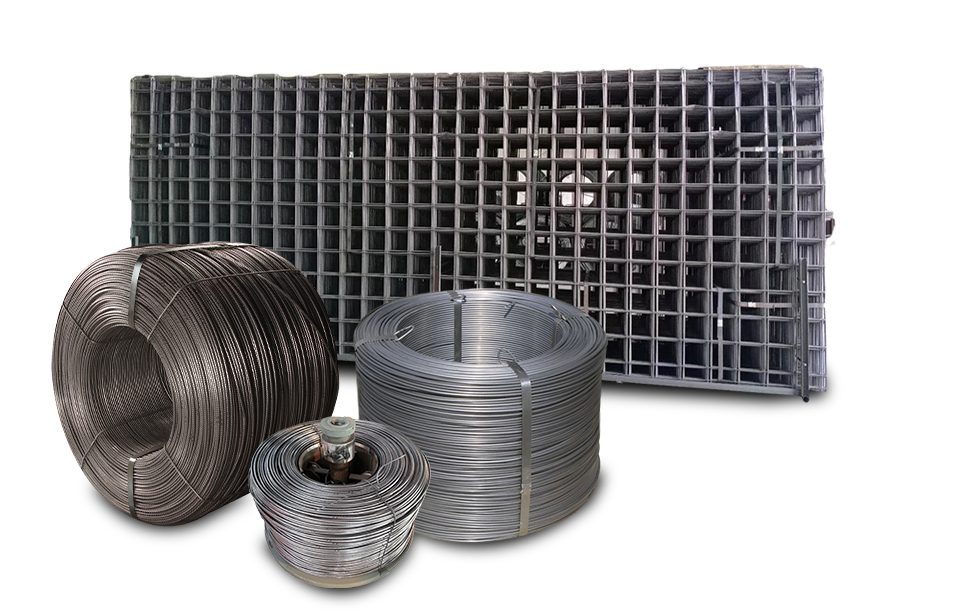

oem welding steel mesh

The Role of OEM Welding Steel Mesh in Modern Manufacturing

In the realm of modern manufacturing, the demand for robust and versatile materials has surged, particularly in the construction and industrial sectors. One such material that has garnered significant attention is welded steel mesh, often produced under Original Equipment Manufacturer (OEM) agreements. This article explores the significance of OEM welding steel mesh, its applications, advantages, and the future of this essential product.

Understanding OEM Welding Steel Mesh

OEM refers to companies that produce components or products that are then marketed by another company under its brand name. In the case of welding steel mesh, OEM manufacturers are responsible for producing high-quality mesh that meets the specific requirements of various industries. The process involves welding together steel rods or wires at intervals to create a grid-like structure, which is then utilized in a myriad of applications.

Welded steel mesh is known for its strength and durability, making it an ideal choice for construction, agriculture, transportation, and even art installations. The ability to customize the size, shape, and spacing of the mesh makes it a versatile solution for different requirements.

Applications of OEM Welding Steel Mesh

1. Construction Industry One of the primary uses of welded steel mesh is in the construction of concrete structures. It is commonly used as reinforcement in slabs, walls, and foundations. By incorporating steel mesh, builders can enhance the tensile strength of concrete, ensuring stability and longevity.

2. Fencing and Barrier Solutions OEM welding steel mesh is frequently utilized in creating fences and barriers for residential and industrial properties. With various designs and sizes available, it can provide security while allowing visibility.

3. Agricultural Uses Farmers use welded steel mesh for fencing livestock and protecting crops. Its resistance to corrosion and robust design make it suitable for outdoor applications, ensuring animals remain secure.

4. Traffic Management and Safety Steel mesh is often employed in road safety applications such as bridge barriers and guardrails. The strength of the welded mesh helps absorb impact, providing greater safety for vehicles and pedestrians.

oem welding steel mesh

5. Artistic and Decorative Structures In the creative realm, welded steel mesh finds its place in sculptures and architectural features. Its malleability allows artists and designers to explore innovative forms and structures.

Advantages of OEM Welding Steel Mesh

1. Customization One of the key benefits of OEM partnerships is the ability to tailor products to specific client requirements. OEM manufacturers can produce welded steel mesh in various sizes, shapes, and specifications, making it adaptable to different applications.

2. Quality Assurance OEM manufacturers often adhere to stringent quality control processes, ensuring that the welded steel mesh meets industry standards and customer expectations. This quality assurance builds trust and reliability among users.

3. Cost-Effectiveness By outsourcing production to OEMs, companies can reduce manufacturing costs without compromising on quality. This not only leads to competitive pricing but also allows businesses to focus on other core areas such as marketing and customer service.

4. Speed of Delivery Working with OEM providers can significantly reduce lead times for product delivery. Manufacturers can rely on established suppliers to meet demand efficiently, allowing them to keep pace with market dynamics.

The Future of OEM Welding Steel Mesh

As industries continue to evolve, the demand for specialized materials like welded steel mesh is likely to grow. Innovations in production techniques, such as automation and advanced welding technologies, are expected to enhance the quality and efficiency of OEM manufacturing processes.

Furthermore, the push for sustainability in manufacturing may lead to the development of eco-friendly welding methods and the use of recycled steel. This shift not only addresses environmental concerns but also appeals to consumers who prioritize sustainability in their purchasing decisions.

In conclusion, OEM welding steel mesh plays a critical role in various industries by providing a strong, customizable, and cost-effective solution for diverse applications. With continuous advancements in technology and a growing focus on sustainability, the future of welded steel mesh manufacturing appears promising, offering endless possibilities for innovation and application.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025