Oct . 19, 2024 02:11 Back to list

oem welded wire mesh sizes for concrete

Understanding OEM Welded Wire Mesh Sizes for Concrete

Welded wire mesh has become an indispensable component in the world of construction, especially for concrete applications. This article explores the importance, specifications, and various sizes of OEM (Original Equipment Manufacturer) welded wire mesh used in concrete reinforcement.

What is Welded Wire Mesh?

Welded wire mesh is a grid-like structure made from steel wires that are welded together at intersections. It serves as a robust reinforcement material that enhances the tensile strength of concrete. This mesh is widely used in various construction projects including slabs, walls, and pavement. The primary purpose of welded wire mesh is to prevent cracks and improve the durability of concrete structures.

Importance of OEM in Welded Wire Mesh

The term OEM refers to manufacturers that produce products for other companies, which then sell them under their own brand name. When it comes to welded wire mesh, OEMs play a critical role as they can provide customized sizes and specifications tailored to specific construction needs. This collaboration allows for a high degree of flexibility and innovation in product design, ensuring that contractors have access to materials that perfectly fit their project requirements.

Standard Sizes of Welded Wire Mesh

Welded wire mesh comes in a variety of sizes and configurations. The size of the welded wire mesh is determined by the spacing of the wires, the diameter of the wires, and the overall dimensions of the mesh sheets. Here are some common specifications

1. Wire Thickness Typically, wire diameters range from 6 gauge (approximately 4.11 mm) to 11 gauge (approximately 3.02 mm). The choice of wire thickness depends on the structural requirements and load-bearing demands of the project.

2. Mesh Size This refers to the distance between each wire in the grid. Common mesh sizes include - 6” x 6” (152 mm x 152 mm) - 4” x 4” (102 mm x 102 mm) - 8” x 8” (203 mm x 203 mm)

oem welded wire mesh sizes for concrete

3. Sheet Size Standard sheets of welded wire mesh typically come in dimensions of 5’ x 10’ (1.52 m x 3.05 m) or 6’ x 12’ (1.83 m x 3.66 m), but custom sizes are often available upon request.

Applications in Concrete

Welded wire mesh is predominantly used for reinforcing concrete due to its ability to distribute loads effectively. Here are some common applications

- Concrete Slabs In residential and commercial construction, welded wire mesh is used in floor slabs to enhance strength and reduce cracking. - Pavement and Driveways Reinforcing the concrete used in pavements and driveways ensures durability under heavy traffic loads. - Walls and Foundations The mesh provides additional support to vertical concrete elements, helping them resist cracking and deformation over time.

Advantages of Using Welded Wire Mesh

The integration of welded wire mesh in concrete construction comes with several benefits

1. Cost-Effective OEM welded wire mesh can reduce material costs when used efficiently in large-scale projects. 2. Enhanced Strength The use of welded wire mesh significantly increases the tensile strength of concrete, providing higher load-bearing capacity. 3. Reduced Cracking With a well-distributed reinforcement, the risk of cracks due to shrinkage, temperature changes, or loading is minimized. 4. Ease of Installation Welded wire mesh is relatively easy to handle and install, making it a favorite among contractors.

Conclusion

In summary, OEM welded wire mesh sizes for concrete applications play a critical role in modern construction. By providing a wide range of sizes and customizable features, OEMs ensure that construction professionals can find the right solution for their specific needs. As the demand for durable and cost-effective concrete solutions continues to rise, the importance of welded wire mesh in the construction industry cannot be overstated. Whether for residential, commercial, or industrial applications, understanding the various specifications and benefits of welded wire mesh is crucial for anyone involved in construction.

-

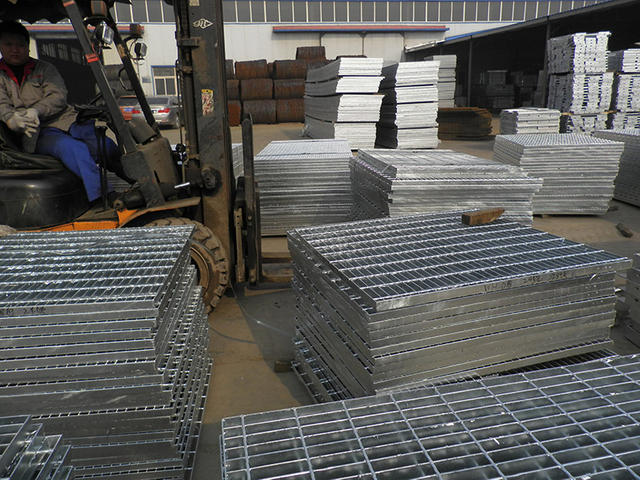

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025