Nov . 01, 2024 02:31 Back to list

Custom Welded Wire Mesh for Various Applications in Iron Fabrication

OEM Welded Wire Mesh Iron A Versatile Solution for Modern Applications

In today's ever-evolving manufacturing landscape, the demand for durable and reliable materials is paramount. Among these materials, OEM welded wire mesh iron has emerged as a popular choice for various applications across multiple industries. This article delves into the characteristics, benefits, and widespread use of OEM welded wire mesh iron.

OEM, or Original Equipment Manufacturer, refers to products that are made to specific standards and specifications asked for by a company that sells the final product. This allows businesses to tailor their offerings to meet unique requirements, ensuring quality and consistency. When it comes to welded wire mesh, this means that the iron mesh is manufactured to precise measurements, wire thicknesses, and mesh sizes that cater to diverse industrial needs.

OEM Welded Wire Mesh Iron A Versatile Solution for Modern Applications

Another significant advantage of this product is its versatility. OEM welded wire mesh iron can be manufactured in various sizes, shapes, and configurations. This adaptability means it can be used in an array of situations, from agricultural applications like animal enclosures and garden trellises to industrial uses in construction and manufacturing. Moreover, the mesh can be coated or galvanized to enhance corrosion resistance, making it suitable for both indoor and outdoor environments.

oem welded wire mesh iron

Ease of installation is another benefit that contributes to the popularity of welded wire mesh iron. The mesh panels can be quickly and easily installed, helping reduce labor costs and project timelines. This attribute is particularly advantageous for construction projects where time is of the essence, allowing contractors to maintain their schedules without compromising on quality.

In addition to its physical properties, the cost-effectiveness of OEM welded wire mesh iron cannot be overlooked. When compared to alternative materials, welded wire mesh often proves to be a more economical solution. Its longevity reduces the need for frequent replacements, thereby lowering overall material costs in the long run. Furthermore, the ease of transport and installation can lead to significant savings in labor costs.

As industries continue to evolve and innovate, the demand for reliable and versatile materials like OEM welded wire mesh iron is poised to grow. Whether it is used in agriculture, construction, or manufacturing, this product offers an unparalleled combination of strength, adaptability, and cost-effectiveness. Companies looking to enhance their manufacturing processes or improve their product offerings would do well to consider the advantages of OEM welded wire mesh iron as a fundamental component of their operations.

In conclusion, OEM welded wire mesh iron stands out as a practical, durable, and economical solution for a multitude of applications. Its robust nature and versatility make it a staple in various sectors, securing its place in the future of modern manufacturing and construction.

-

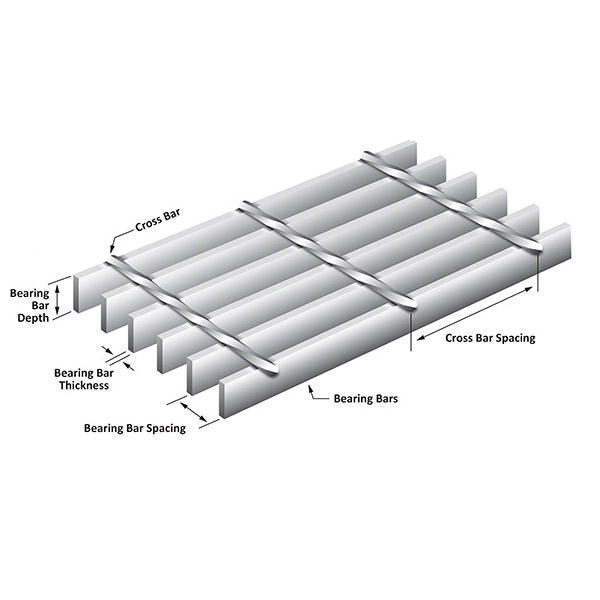

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025