Nov . 18, 2024 02:26 Back to list

Custom Welded Wire Mesh Solutions for Industrial Applications and Projects

The Importance of OEM Welded Wire Mesh in Industrial Applications

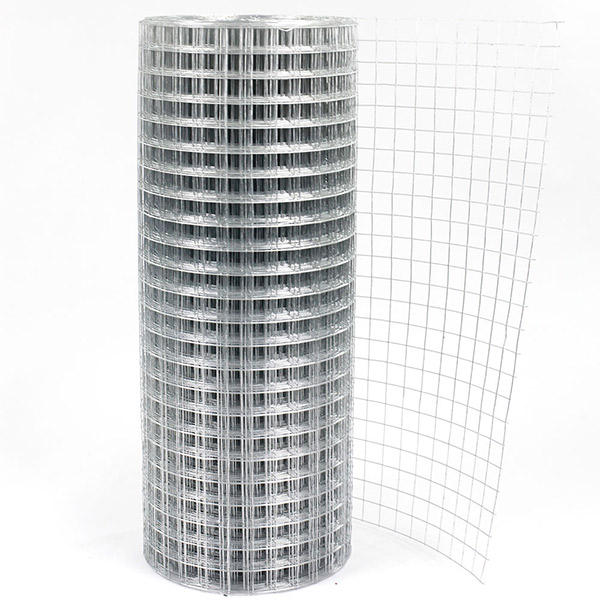

In modern manufacturing and industrial processes, the necessity for reliable and durable materials cannot be overstated. One such material that has gained significant traction is OEM welded wire mesh. This specialized form of wire mesh offers numerous advantages, particularly for industries that require high strength, durability, and customization.

OEM, or Original Equipment Manufacturer, welded wire mesh is produced to meet specific requirements set by manufacturers. This adaptability ensures that the welded wire mesh can cater to a diverse range of industries, including construction, agriculture, automotive, and more. The mesh is typically made from high-quality steel wire that is welded at each intersection, creating a robust and reliable structure that can withstand harsh environments.

One of the primary benefits of OEM welded wire mesh is its versatility. It can be produced in various sizes, wire gauges, and mesh configurations tailored to precise specifications. This customization allows industries to implement wire mesh solutions that perfectly fit their operational needs. For instance, in the construction sector, welded wire mesh may be used for reinforcement in concrete structures, ensuring enhanced strength and stability.

oem welded wire mesh for industry

Furthermore, OEM welded wire mesh is known for its exceptional strength. The welding process creates a fused junction at each intersection, resulting in a stronger structure compared to non-welded alternatives. This is particularly vital in applications where safety and reliability are paramount. For instance, in the automotive industry, welded wire mesh may be used in the production of safety cages or grilles, where the integrity of the structure is crucial for protecting both the vehicle and its occupants.

Another significant advantage is the cost-effectiveness of OEM welded wire mesh. While the initial investment may be higher compared to other materials, its durability and longevity lead to reduced maintenance costs over time. Industries benefit from lower replacement frequencies, making welded wire mesh a smart choice for those looking to optimize their operational budgets.

In addition to strength and cost-effectiveness, welded wire mesh offers excellent ventilation and visibility, making it ideal for storage areas and fencing solutions. Its open structure allows for airflow while still providing security, which is essential for environments such as warehouses and factories.

In conclusion, OEM welded wire mesh plays a vital role in various industrial applications. Its combination of strength, customization, and cost-effectiveness makes it an indispensable material for manufacturers across sectors. By investing in quality welded wire mesh, industries can enhance their operational efficiency while ensuring safety and reliability in their processes. As technology continues to advance, the demand for such resilient materials is likely to grow, highlighting the importance of OEM welded wire mesh in the future of industrial operations.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025