Dec . 11, 2024 11:02 Back to list

OEM Welded Wire Mesh Machine for Efficient Production and Custom Solutions

The Rise of OEM welded wire machine mesh Revolutionizing the Wire Industry

In the ever-evolving industrial landscape, the demand for high-quality wire products has seen a significant increase. Among the various types of wire processing technologies, OEM (Original Equipment Manufacturer) welded wire mesh machines have emerged as a pivotal innovation that caters to multiple sectors, including construction, agriculture, and security. This article delves into the workings, benefits, applications, and future of OEM welded wire machine mesh, spotlighting its transformative role in the wire industry.

Understanding OEM Welded Wire Mesh Machines

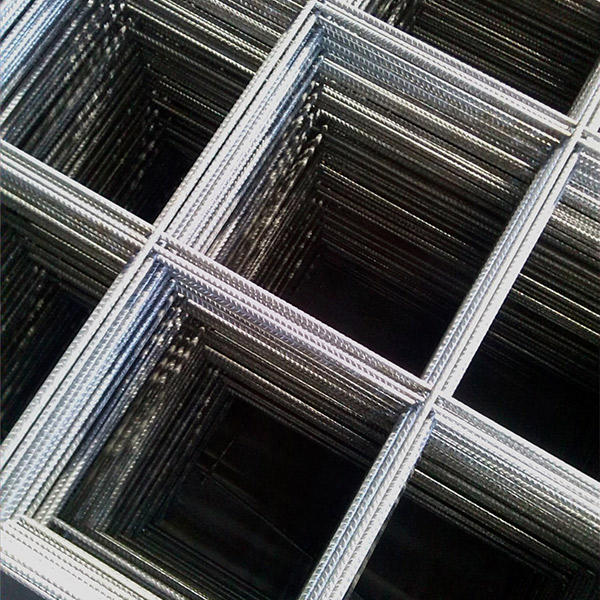

OEM welded wire mesh machines are specialized tools designed to fabricate welded wire mesh with precision and efficiency. These machines utilize advanced technologies that allow for the automatic welding of wires at specified intervals, creating a robust mesh structure. This automated process not only enhances production efficiency but also ensures consistent quality, which is imperative in meeting the increasing demands of various industries.

The machines work by feeding wire through a series of rollers and aligning it into a grid format. After aligning, the wires are welded together using electric resistance welding, which generates heat to fuse the wires at their intersection points. Once welded, the mesh is cut into specified dimensions, making it ready for various applications.

Benefits of OEM Welded Wire Mesh Machines

1. High Efficiency One of the most significant advantages of using OEM welded wire mesh machines is their operational efficiency. These machines can produce large quantities of mesh in a short amount of time, thus meeting high market demands without compromising quality.

2. Customization OEM manufacturers often provide options for customization, allowing businesses to specify the wire diameter, mesh size, and even the materials used. This flexibility caters to the unique needs of different industries, ensuring that clients receive products tailored to their specific requirements.

3. Cost-Effectiveness By automating the welding process, companies can significantly reduce labor costs. The efficiency of these machines also leads to minimized material waste, contributing to lower overall production costs.

4. Consistency and Quality Control The automatic nature of OEM welded wire machines ensures that each piece of mesh produced meets strict quality criteria. This consistency is crucial for applications where strength and durability are paramount, such as in fencing or reinforcement structures.

oem welded wire machine mesh

5. Versatility OEM welded wire mesh finds applications in diverse sectors, including agriculture (for livestock enclosures and crop protection), construction (for concrete reinforcement), and security (as fencing and barrier solutions). This versatility enhances the machine's market appeal.

Applications of Welded Wire Mesh

The applications of OEM welded wire mesh are vast and varied. In the construction industry, it is widely used for reinforcing concrete structures, offering additional strength and stability. In agriculture, welded wire mesh is essential for creating enclosures for animals and protecting crops from pests. Additionally, it plays a critical role in the security sector, where it is utilized for fencing, gates, and barriers to safeguard properties.

Moreover, the automotive and manufacturing sectors leverage welded wire mesh for creating safe storage solutions, rack systems, and mesh containers. Its durable composition and customizable attributes make it an ideal choice for countless applications across different industries.

The Future of OEM Welded Wire Machine Mesh

As technology continues to advance, the future of OEM welded wire machine mesh looks promising. Innovations in automation, such as the incorporation of AI and IoT technologies, are likely to enhance machine efficiency and production capabilities further. Moreover, the rising focus on sustainability and eco-friendly practices will push manufacturers to explore recyclable materials and energy-efficient processes.

The global market for welded wire mesh is expected to grow, driven by increasing demands from various sectors. OEM manufacturers that stay ahead of technological trends and prioritize quality and customization will likely thrive in this competitive landscape.

Conclusion

In conclusion, OEM welded wire mesh machines represent a significant advancement in the wire processing industry. Their ability to produce high-quality, customizable welded wire mesh efficiently has transformed how businesses meet the demands of various sectors. With a bright future ahead, these machines will undoubtedly play an instrumental role in shaping the wire industry landscape for years to come.

-

Welded Wire Mesh for Industry Factory - Anping County Puersen Hardware Wire Mesh Products Co., Ltd.

NewsAug.29,2025

-

Welded Wire Mesh for Industry Factory | Durable & Cost-Effective Solutions

NewsAug.29,2025

-

Durable Welded Wire Mesh for Industry Factory | Custom Solutions

NewsAug.27,2025

-

Durable Welded Wire Mesh for Industry Factory - High Quality

NewsAug.26,2025

-

Leading Galvanized Steel Fence Factory | Durable & Secure Fencing

NewsAug.24,2025

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025