Nov . 07, 2024 12:27 Back to list

OEM Welded Wire Mesh Machine for Efficient Production Solutions

Welded Wire Mesh Production The Role of OEM Machines

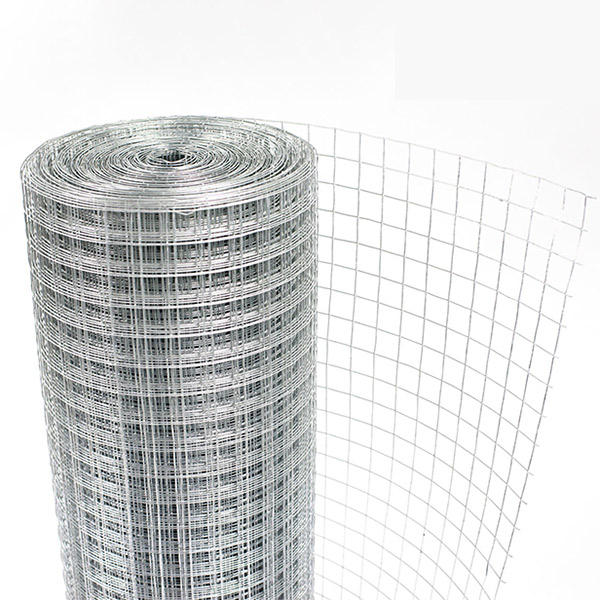

Welded wire mesh is an essential component in various industries, ranging from construction to agriculture and even arts and crafts. As the demand for durable and versatile mesh continues to grow, manufacturers are turning to original equipment manufacturer (OEM) welded wire mesh machines to increase efficiency and improve product quality. This article explores the significance of OEM welded wire mesh machines, their advantages, and the future of mesh production.

Understanding OEM Welded Wire Machines

OEM welded wire machines are specialized devices designed for the production of welded wire mesh at an industrial scale. These machines automate the processes of wire feeding, welding, and cutting, ensuring high precision and uniformity in the mesh produced. The term OEM refers to the original equipment manufacturer, indicating that these machines are specifically designed for the manufacturers who use them, tailored to their unique specifications and needs.

Key Advantages of OEM Welded Wire Machines

1. Customization One of the primary advantages of OEM machines is their ability to be customized according to the specific requirements of a manufacturer. Whether it’s the wire diameter, mesh opening size, or production volume, OEM machines can be tailored to meet diverse needs, providing flexibility not found in off-the-shelf solutions.

2. Increased Efficiency The automation of the welding and mesh production process significantly enhances productivity. OEM machines can operate at high speeds, reducing production times and allowing manufacturers to meet market demands more effectively. This efficiency translates into lower operational costs and higher profit margins.

3. Consistency and Quality Quality control is crucial in manufacturing, and OEM welded wire machines excel in maintaining consistent quality. Automated systems minimize human error, ensuring that every mesh produced adheres to the required standards. This reliability builds trust with customers, fostering long-term relationships.

oem welded wire machine mesh

4. Reduced Labor Costs By automating the production process, OEM machines significantly reduce the need for manual labor. Automating repetitive tasks not only cuts down on labor costs but also allows skilled workers to focus on more complex tasks that require human insight and creativity.

5. Technological Advancements With the rapid advancement of technology, modern OEM welded wire machines come equipped with intelligent features. These machines may include digital displays, automatic monitoring systems, and integration with other production software, providing manufacturers with the tools they need to optimize operations.

The Future of Welded Wire Mesh Production

As industries continue to evolve, the demand for welded wire mesh is expected to rise. Innovations in materials and design will push manufacturers to adopt more advanced automated solutions. Additionally, the push for sustainability will likely influence the production processes, encouraging the development of machines that utilize eco-friendly materials and reduce waste.

Manufacturers are also exploring the integration of IoT (Internet of Things) technologies within OEM welded wire machines. This integration allows for real-time monitoring and predictive maintenance, ensuring that any potential issues are addressed before they lead to costly downtime. Such advancements not only improve efficiency but also extend the life of the machines.

Conclusion

The significance of OEM welded wire mesh machines cannot be overstated. They are transforming how manufacturers produce mesh, combining customization, efficiency, and quality into a single package. As the demand for welded wire mesh continues to grow across various sectors, manufacturers must embrace these advanced machines to stay competitive in the market. The future of welded wire mesh production lies in the hands of technology, and those who adopt it will undoubtedly thrive in an increasingly demanding landscape. Investing in OEM welded wire mesh machines is not just about keeping up with trends; it’s about paving the way for innovation and excellence in production.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025