Oct . 15, 2024 09:15 Back to list

OEM Steel Wire Mesh Pricing for Quality and Durability Solutions

Understanding OEM Steel Wire Mesh Prices Factors and Trends

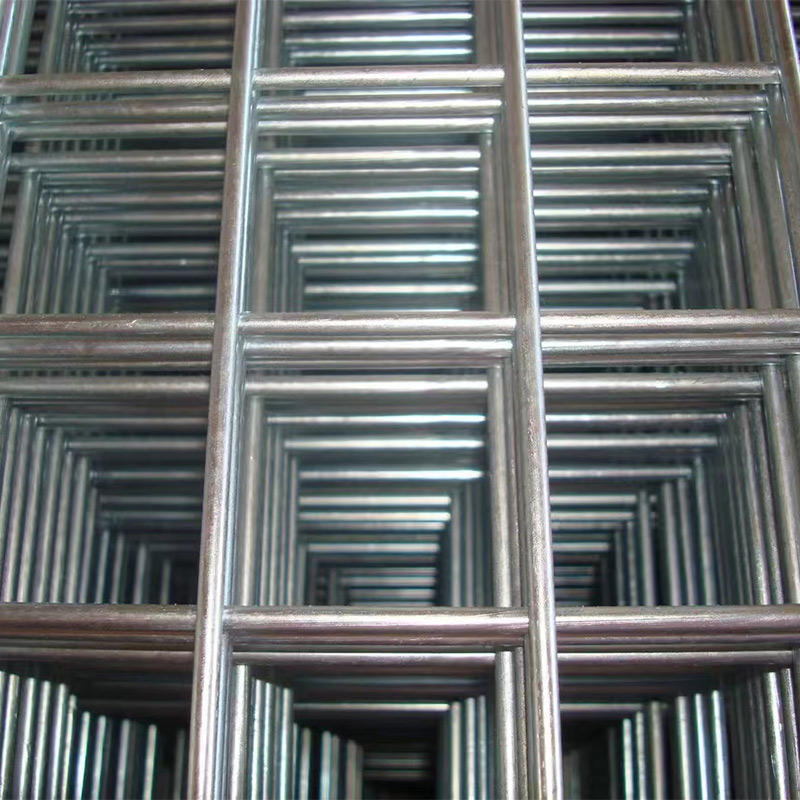

In the world of manufacturing and construction, steel wire mesh stands as a critical component, widely utilized for various purposes including reinforcement in concrete structures, fencing, industrial use, and many more. The price of OEM (Original Equipment Manufacturer) steel wire mesh is influenced by a myriad of factors, making it essential for buyers and businesses to understand these dynamics to make informed purchasing decisions.

Overview of Steel Wire Mesh

Steel wire mesh is produced by welding or weaving together wires into a grid pattern. It can be made in a variety of sizes, gauges, and specifications according to its intended application. OEM steel wire mesh refers to products manufactured by a company to another company's specifications, usually for use in their products or for resale. This type of mesh often provides enhanced performance tailored to specific requirements.

Key Factors Influencing Prices

1. Material Quality The grade of steel used to manufacture the wire mesh greatly influences its price. High-quality steel that offers greater durability and resistance to corrosion tends to be more expensive. Buyers must evaluate the specific requirements of their projects to determine the appropriate material.

2. Production Methods The method of production also plays a significant role in the pricing of steel wire mesh. There are primarily two production techniques welding and weaving. Welding generally results in a stronger product but may come at a higher cost compared to woven mesh due to the higher energy requirements and labor involved.

3. Mesh Size and Design The dimensions of the mesh, including the thickness of the wire and the size of the openings, impact the price. Custom designs or non-standard sizes typically increase manufacturing costs, which in turn raises the selling price.

4. Volume and Order Size Like many industrial materials, the price per unit of steel wire mesh decreases with larger order sizes. Bulk purchases allow manufacturers to spread the fixed costs over a larger quantity, resulting in lower prices per unit. Therefore, companies planning for significant usage in their projects can benefit from negotiating bulk pricing.

oem steel wire mesh price

5. Market Demand and Supply The prices of steel wire mesh are also subject to market dynamics. Fluctuations in demand due to construction booms or slowdowns can lead to pricing volatility. When demand is high, prices tend to rise, while a surplus in supply can lead to competitive price reductions.

6. Geographical Factors Transportation costs and local production capacity can also influence pricing. If manufacturers are located far from the end-users, the shipping costs can add significantly to the final price. Additionally, regional disparities in the availability of raw materials can lead to varying pricing structures.

7. Regulatory Compliance Compliance with local regulations and quality standards can impose additional costs on manufacturers. For instance, products need to be manufactured using certain safety standards which might require higher-gauge materials, impacting the overall price.

Current Trends in the Market

In recent years, there has been a growing trend towards sustainability and eco-friendliness in manufacturing. A shift towards recycled steel in wire mesh production not only meets environmental standards but also affects pricing strategies. Recycled materials can lead to cost reductions, which may be beneficial for cost-conscious buyers.

Moreover, advancements in manufacturing technology are paving the way for more efficient production processes. Automation and improved welding techniques can reduce labor costs and production times, allowing manufacturers to offer more competitive pricing without compromising quality.

Conclusion

When considering the purchase of OEM steel wire mesh, it is crucial to understand the factors that affect pricing. By evaluating material quality, production methods, order sizes, and market trends, buyers can position themselves to negotiate better deals. Staying informed about fluctuations in the market can also provide insights into the best times to purchase and secure favorable pricing. Ultimately, making an informed purchasing decision will ensure that businesses receive the right product at the right price, meeting their application needs effectively and efficiently.

-

Hot Dipped Galvanized Steel Grating Durable & Corrosion-Resistant Solutions

NewsMay.31,2025

-

Plastic-Coated Hexagonal Wire Mesh Manufacturer Durable Solutions

NewsMay.31,2025

-

Reinforced Concrete Expanded Metal Mesh Suppliers & Factories High-Strength

NewsMay.31,2025

-

Galvanized Steel Wire High-Strength, Rustproof Material & Suppliers

NewsMay.30,2025

-

1 Inch Hexagonal Wire Mesh Heavy-Duty Factories & Suppliers

NewsMay.30,2025

-

Green PVC Coated Wire Durable, Weather-Resistant Electrical Solutions

NewsMay.30,2025