Nov . 30, 2024 10:05 Back to list

OEM Standard Welded Wire Mesh Dimensions and Specifications for Various Applications

Understanding OEM Standard Welded Wire Mesh Sizes

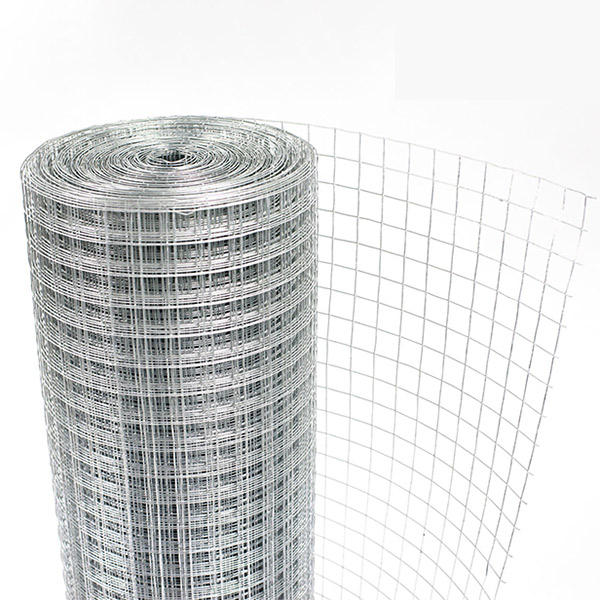

Welded wire mesh is a versatile and widely used material in various industries, including construction, agriculture, and manufacturing. As the demand for specific sizes and specifications increases, OEM (Original Equipment Manufacturer) standards for welded wire mesh play a crucial role in ensuring quality and consistency. In this article, we will delve into the significance of OEM standard welded wire mesh sizes, their applications, benefits, and factors to consider when choosing the right mesh for your project.

What is Welded Wire Mesh?

Welded wire mesh consists of intersecting wires that are welded together at various intervals, forming a grid-like structure. This fabrication technique enhances the strength and durability of the mesh. Welded wire mesh is available in various materials, including galvanized steel, stainless steel, and PVC-coated wires. It comes in a range of sizes and configurations, making it suitable for numerous applications ranging from fencing and reinforcement to filtration and confinement.

Importance of OEM Standards

OEM standards provide a benchmark for quality and performance in the production of welded wire mesh. Adhering to these standards ensures that the mesh can withstand the stresses and strains it may encounter in practical applications. Key advantages of adhering to OEM standards include

1. Quality Assurance OEM standards guarantee that welded wire mesh is produced with precise specifications, ensuring uniformity in wire gauge, mesh size, and spacing.

2. Compatibility OEM-compliant mesh is designed to meet specific performance criteria. This ensures compatibility with various equipment and applications, eliminating the risk of incompatibility issues.

3. Reputation and Trust Manufacturers that comply with OEM standards often enjoy a better reputation among clients and stakeholders, leading to increased trust and more business opportunities.

Common Mesh Sizes

Welded wire mesh comes in various sizes, which can be categorized by wire diameter, mesh opening, and panel size. Common mesh sizes include

- Wire Diameter Typically ranges from 1.2 mm to 5 mm, with options for heavier gauges for higher strength applications. - Mesh Opening Standard openings can vary widely, with common sizes including 1 inch x 1 inch, 2 inch x 2 inch, or smaller configurations such as 0.5 inch x 0.5 inch for more delicate applications.

- Panel Size Welded wire mesh panels can be manufactured in various sizes, commonly ranging from 4 feet x 8 feet to larger configurations for specialized uses.

Applications of Welded Wire Mesh

oem standard welded wire mesh size

Welded wire mesh has numerous applications across various industries, including

1. Construction Used for reinforcing concrete structures, providing enhanced strength and durability.

2. Agriculture Commonly utilized for fencing livestock, garden enclosures, and crop protection.

3. Manufacturing Employed in the production of screens, trays, and baskets for parts sorting and safety barriers.

4. DIY Projects Popular among hobbyists for creating home improvement projects, such as garden trellises, birdcages, and storage solutions.

Factors to Consider When Choosing Welded Wire Mesh

When selecting welded wire mesh, consider the following factors to ensure the right fit for your project

1. Purpose Define the intended use of the mesh—whether it’s for structural reinforcement, fencing, or decorative purposes.

2. Material Choose a suitable material based on environmental exposure—galvanized steel for corrosion resistance, stainless steel for longevity, or coated options for aesthetics.

3. Size and Configuration Review the specific OEM sizes available and select the mesh that meets your dimensional requirements.

4. Load-bearing Capacity Assess the required strength based on the expected loads and stresses.

Conclusion

Understanding OEM standard welded wire mesh sizes is essential for selecting the right mesh for any project. By adhering to these standards, manufacturers can ensure quality, consistency, and compatibility, which ultimately leads to successful applications across various fields. Whether you’re in construction, agriculture, or another industry, choosing the right welded wire mesh is crucial for achieving the desired performance and durability. With the right knowledge and resources, you can make informed decisions that align with your project’s needs.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025