Dec . 13, 2024 01:16 Back to list

oem low carbon cold drawn steel wire 3mm

The Rise of Low Carbon Cold Drawn Steel Wire A Focus on OEM Applications

In recent years, the manufacturing industry has witnessed a surge in demand for low carbon cold drawn steel wire, particularly in the context of Original Equipment Manufacturer (OEM) applications. This specialized steel wire is noted for its excellent mechanical properties, dimensional accuracy, and versatility, making it a preferred choice in various industrial sectors.

Understanding Low Carbon Cold Drawn Steel Wire

Low carbon cold drawn steel wire is manufactured from low carbon steel, which contains a low percentage of carbon (typically less than 0.30%). The cold drawing process involves reducing the diameter of the wire through a series of dies at room temperature, resulting in a smoother finish and improved strength compared to conventional wire. This process not only enhances the tensile strength but also increases the wire's yield strength, making it ideal for applications requiring high performance and durability.

The primary characteristics of low carbon cold drawn steel wire include excellent ductility, good weldability, and enhanced surface finish. These attributes make the wire suitable for various uses, ranging from automotive components to construction materials and even in the manufacture of springs and fasteners.

Applications in OEM Industries

In OEM applications, low carbon cold drawn steel wire serves as a crucial component in the production of a wide array of products. One of the most significant advantages it offers is the ability to meet specific design requirements. OEMs often require materials that can be custom-tailored to fit their unique specifications, and cold drawn steel wire can be produced in various diameters, tensile strengths, and mechanical properties to meet these demands.

Automotive Industry

The automotive industry is one of the largest consumers of low carbon cold drawn steel wire. It is used in the production of critical components such as suspension systems, brake cables, and steering rods. The wire's ability to withstand stress and fatigue makes it a reliable choice for these applications. Additionally, the lightweight nature of low carbon steel contributes to overall vehicle efficiency, making it an environmentally friendly option for OEMs focused on reducing emissions and enhancing fuel economy.

oem low carbon cold drawn steel wire 3mm

Construction and Infrastructure

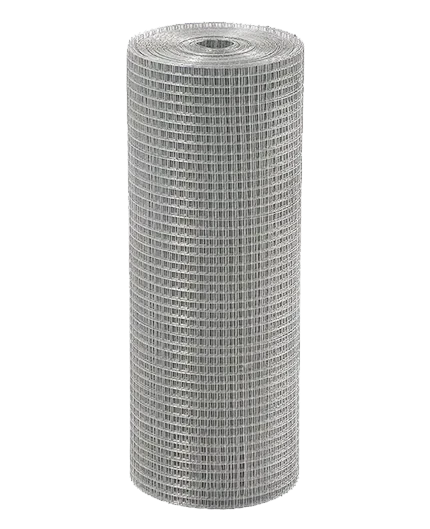

In the construction sector, low carbon cold drawn steel wire is extensively used in the manufacturing of reinforcing bars, wire ropes, and mesh. These materials are integral to providing the necessary strength and stability required in building structures. The wire's corrosion resistance is also vital in ensuring longevity and durability, particularly in harsh environmental conditions. As buildings and infrastructure increasingly prioritize sustainability, low carbon steel wire is an excellent choice due to its recyclability and lower carbon footprint compared to higher carbon alternatives.

Industrial and Specialty Applications

Beyond automotive and construction, low carbon cold drawn steel wire is utilized in various industrial applications. For instance, it is commonly used in the production of springs, fasteners, and other specialty components. The precise manufacturing capabilities of cold drawn wire allow OEMs to create intricate designs and profiles that meet specific operational requirements.

Environmental Considerations

The focus on sustainability has led many manufacturers to adopt low carbon steel processes. The production of low carbon cold drawn steel wire typically requires less energy than higher carbon alternatives, contributing to reduced greenhouse gas emissions. Moreover, the recyclability of steel means that OEMs can create closed-loop systems, minimizing waste and promoting a circular economy.

Conclusion

In conclusion, the demand for low carbon cold drawn steel wire continues to rise in OEM applications across various industries. Its superior mechanical properties, customization potential, and sustainability advantages make it an ideal choice for manufacturers looking to enhance their product offerings. As industries evolve and the emphasis on eco-friendly practices intensifies, low carbon cold drawn steel wire is poised to play a vital role in the future of manufacturing. Embracing this innovative material will not only drive performance and efficiency but also propel the industry towards a more sustainable future.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025