Nov . 29, 2024 13:31 Back to list

OEM Galvanized Wire for Durable and Reliable Industrial Applications

Understanding OEM Galvanized Wire Quality, Applications, and Benefits

OEM (Original Equipment Manufacturer) galvanized wire is an essential component in various industries, celebrated for its durability, corrosion resistance, and versatility. As a widely used material, galvanized wire plays a pivotal role in numerous applications, ranging from construction to agriculture. This article delves into the characteristics, manufacturing process, and benefits of OEM galvanized wire, while also exploring its diverse applications.

What is Galvanized Wire?

Galvanized wire is steel wire that has been coated with a layer of zinc to protect it from corrosion. The process of galvanization involves dipping the steel wire in molten zinc or applying a zinc coating through electroplating. This protective layer ensures that the wire can withstand harsh environmental conditions, making it ideal for outdoor applications. The term OEM refers to products made by one company to be marketed by another, which is particularly relevant in the context of galvanized wire used in manufacturing and construction.

Manufacturing Process

The production of OEM galvanized wire begins with high-quality steel wire rod, which is drawn into various thicknesses suitable for different applications. Once the desired diameter is achieved, the wire undergoes the galvanization process. The two primary methods of galvanization are hot-dip galvanization and electro-galvanization.

- Hot-dip Galvanization In this process, the wire is immersed in a bath of molten zinc. The zinc adheres to the steel wire, creating a robust coating that provides excellent corrosion resistance. This method is favored for its long-lasting protective qualities.

- Electro-galvanization This technique employs an electrolytic process to apply a thin layer of zinc to the wire. While it produces a smooth finish and is suitable for applications where aesthetics are important, it may not provide the same level of corrosion protection as hot-dip galvanization.

Applications

OEM galvanized wire is utilized in a broad range of applications due to its strength and resistance to rust. Some of the most common uses include

1. Construction Galvanized wire is widely used in building and construction for reinforcing concrete structures, in the production of wire mesh, and for various fixtures and fittings that require durability.

oem galvanized wire

2. Agriculture Farmers often use galvanized wire for fencing and securing enclosures for livestock. Its resistance to weathering ensures that it lasts longer in rural settings where exposure to the elements is significant.

3. Manufacturing OEM galvanized wire is used in the production of various manufactured goods such as springs, fasteners, and automotive components where strength and corrosion resistance are crucial.

4. Electrical Wiring Galvanized wire can also be found in electrical applications, where it is used for grounding and in certain fencing applications to support electrical wiring.

Benefits

The use of OEM galvanized wire comes with several benefits

- Corrosion Resistance The primary advantage of galvanized wire is its ability to resist rust and corrosion, extending the lifespan of the wire and the structures it supports.

- Strength and Durability Galvanized wire maintains high tensile strength, making it suitable for a wide range of demanding applications.

- Cost-Effectiveness The longevity and durability of galvanized wire contribute to its cost-effectiveness, reducing the need for frequent replacements and maintenance.

- Versatility With a variety of thicknesses and coatings available, OEM galvanized wire can be tailored to meet the specific needs of different industries.

In summary, OEM galvanized wire is a robust, versatile material that plays a vital role across multiple sectors. Its resistance to corrosion, strength, and adaptability make it a preferred choice for various applications, ensuring that it remains an integral part of modern manufacturing and construction processes. Whether for industrial use or creative projects, galvanized wire continues to be a reliable solution in an ever-evolving marketplace.

-

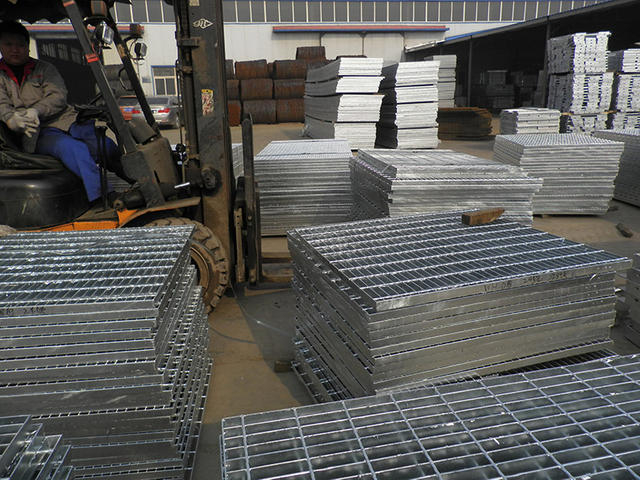

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025