Nov . 11, 2024 01:15 Back to list

Custom Galvanized Wire Solutions for Various Industrial Applications and Needs

The Versatility and Applications of OEM Galvanized Wire

In today's industrial landscape, the demand for durable and reliable materials is crucial for the successful operation of numerous applications. One such material that has gained prominence is OEM (Original Equipment Manufacturer) galvanized wire. This type of wire, known for its corrosion-resistant properties and strength, plays a vital role in various sectors, including construction, agriculture, telecommunications, and manufacturing.

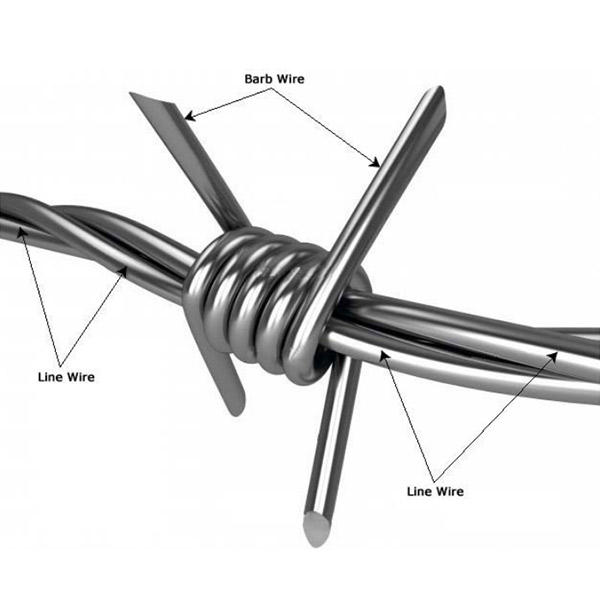

Galvanized wire is steel wire that has been coated with a layer of zinc to protect against rust and corrosion. The process of galvanization enhances the wire's longevity, making it suitable for outdoor applications where exposure to harsh weather conditions is inevitable. The OEM designation refers to wire that is manufactured based on specifications provided by another company, allowing businesses to obtain customized wire solutions tailored to their specific needs.

The Versatility and Applications of OEM Galvanized Wire

In agriculture, galvanized wire proves indispensable for creating enclosures and fencing systems. Farmers use this durable wire to keep livestock secure and to protect crops from wildlife. Galvanized wire is resistant to rust and degradation, which means it can endure the elements without losing its integrity. Additionally, its affordability makes it a popular choice among farmers looking for cost-effective yet reliable fencing solutions.

oem galvanized wire

Another significant application of OEM galvanized wire is within the telecommunications sector. The wire is often used in the construction of telecommunication towers, providing stability and support for antennas and lines. The corrosion resistance of galvanized wire is particularly advantageous in this context, as towers are frequently exposed to the elements, necessitating materials that can withstand wind, rain, and humidity without deteriorating.

Moreover, OEM galvanized wire has found its way into various manufacturing processes. Industries that require high tensile strength and precision often turn to galvanized wire for component fabrication. It is commonly used to produce springs, wire forms, and other critical components that demand reliability under stress. The customization options available through OEM manufacturing mean that businesses can specify gauge, length, and tensile strength to match their production requirements seamlessly.

While the versatility of OEM galvanized wire is notable, the environmental impact of its production and use should not be overlooked. Manufacturers are increasingly adopting eco-friendly practices to minimize their carbon footprint while producing galvanized wire. Many companies are also exploring alternative methods of galvanization that reduce waste and energy consumption, contributing to a more sustainable future in the wire industry.

In conclusion, OEM galvanized wire is a crucial material that supports a broad spectrum of applications across various industries. Its corrosion-resistant properties, strength, and customization options make it an ideal choice for construction, agriculture, telecommunications, and manufacturing. As industries continue to evolve and seek sustainable practices, the demand for OEM galvanized wire is likely to grow, solidifying its role as a backbone material in modern manufacturing and construction. The next time you encounter reinforced structures, agricultural fences, or communication towers, take a moment to appreciate the vital role that OEM galvanized wire plays in keeping these systems secure and effective.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025