Dec . 11, 2024 05:33 Back to list

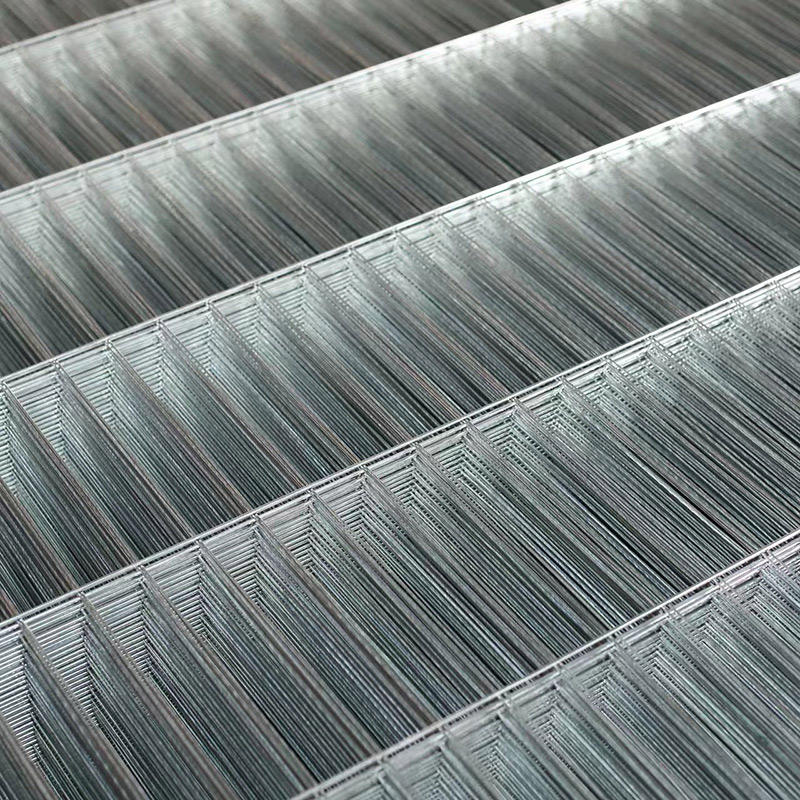

High-Quality OEM Galvanized Welded Wire Mesh for Various Applications

The Versatility of OEM Galvanized Welded Mesh

In the realm of construction and industrial applications, materials play a pivotal role in ensuring structural integrity and durability. Among these, OEM (Original Equipment Manufacturer) galvanized welded mesh has emerged as a favored choice due to its numerous benefits and versatile applications. This article will explore the characteristics, manufacturing process, and diverse uses of galvanized welded mesh, highlighting its significance in various sectors.

Understanding Galvanized Welded Mesh

Galvanized welded mesh is a type of fencing or netting created by welding together steel wires at intersecting points. The term “galvanized” refers to the process of coating the steel with a protective layer of zinc to prevent rust and corrosion. This manufacturing technique not only enhances the metal's longevity but also ensures that it maintains structural strength under various conditions. The welded mesh can be produced in different wire diameters and mesh sizes, allowing for customized applications tailored to specific needs.

Manufacturing Process

The production of OEM galvanized welded mesh involves several critical steps

1. Wire Selection High-quality steel wires are chosen based on the intended use of the mesh. The diameter of the wires can vary, influencing the strength and flexibility of the final product.

2. Welding The selected wires are precisely welded together at each intersection, creating a strong and stable grid pattern. This welding process ensures that the joints are robust, contributing to the overall durability of the mesh.

3. Galvanization After welding, the mesh is galvanized using either hot-dip or electro-galvanizing methods. Hot-dip galvanization involves immersing the welded mesh in molten zinc, providing a thick coating for maximum protection. In contrast, electro-galvanizing uses an electric current to apply a thinner zinc layer for corrosion resistance.

4. Quality Control Each batch undergoes stringent quality control checks to ensure it meets specific industry standards. This vigilance ensures that the finished product is free from defects and suitable for a range of applications.

oem galvanized welded mesh

Applications of Galvanized Welded Mesh

The versatility of OEM galvanized welded mesh makes it suitable for a wide variety of applications

1. Construction In the construction industry, galvanized welded mesh is often used for concrete reinforcement. Its strength and durability enhance the load-bearing capacity of structures, making it an essential component in building foundations, roads, and bridges.

2. Fencing The mesh serves as an effective fencing solution for agricultural, industrial, and residential properties. Its corrosion-resistant properties make it ideal for outdoor use, keeping livestock safe and providing security for properties.

3. Security Grilles Galvanized welded mesh is used in the manufacturing of security grilles and barriers. Its inherent strength deters unauthorized access while allowing visibility and airflow, making it an optimal choice for commercial premises.

4. Industrial Applications In industrial settings, the mesh is utilized for various purposes, including shelving, storage, and partitioning. Its durability and low maintenance requirements make it an economical choice for factories and warehouses.

5. Garden and Landscaping Gardeners often use galvanized welded mesh for plant supports, trellises, and fencing to protect plants from animals. Its robustness ensures that it withstands the elements while providing necessary support for climbing plants.

Conclusion

In summary, OEM galvanized welded mesh is an incredibly versatile product that serves numerous industries, from construction to agriculture. Its combination of strength, durability, and corrosion resistance makes it an ideal choice for a wide range of applications. As demand for durable and reliable materials continues to grow, the usage of galvanized welded mesh is expected to expand further, solidifying its place as a cornerstone in both industrial and domestic settings. Whether reinforcing structures or providing security, galvanized welded mesh stands out as a practical solution for modern construction and design challenges.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025