Nov . 04, 2024 13:24 Back to list

Custom Galvanized Iron Welded Wire Mesh for Various Applications and Projects

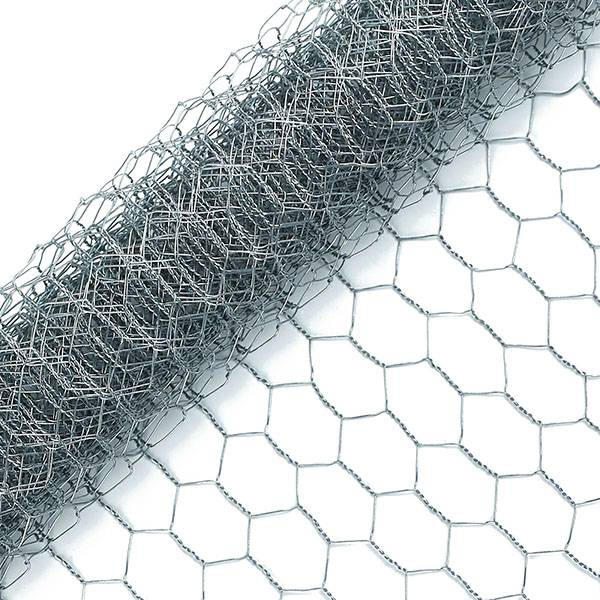

The Versatility and Applications of OEM Galvanized Iron Welded Wire Mesh

In the realm of construction and industrial applications, the use of welded wire mesh has gained substantial prominence, particularly galvanized iron welded wire mesh. As an integral component in numerous projects, this material boasts durability, corrosion resistance, and versatility that makes it an ideal choice for various applications.

Understanding Galvanized Iron Welded Wire Mesh

Galvanized iron welded wire mesh is created by welding together strands of iron wire, which is then coated with a layer of zinc to provide a protective barrier against environmental factors. This galvanization process significantly enhances the lifespan of the wire mesh, making it resistant to rust and corrosion. The welded design provides structural integrity, ensuring that the mesh maintains its shape and strength under stress.

The manufacturing process essentially involves bending and welding iron wires at intersections, thus forming a grid-like structure that can be customized in terms of wire thickness, mesh size, and dimension. This customization allows manufacturers to cater to specific customer needs, often marked by the term OEM (Original Equipment Manufacturer).

Benefits of OEM Galvanized Iron Welded Wire Mesh

1. Durability and Longevity The galvanization process protects the iron from moisture and oxidizing elements, resulting in a product that can endure harsh weather conditions. This durability makes it suitable for both indoor and outdoor applications.

2. Cost-Effectiveness While the initial investment in galvanized wire mesh might be slightly higher than non-galvanized options, the long-term savings are notable due to its longevity and reduced need for replacements or repairs.

3. Flexibility in Design OEM manufacturers can produce wired mesh tailored to specific applications. Whether it's for garden fencing, animal enclosures, or industrial applications, the ability to customize mesh sizes and thickness allows for a broad range of uses.

4. Ease of Installation Galvanized welded wire mesh is relatively easy to handle and install. Its structural consistency ensures that it can be quickly and efficiently set up, reducing labor time and costs.

5. Aesthetic Appeal Apart from its functional applications, galvanized wire mesh can also serve aesthetic purposes in residential and commercial landscaping. It can blend seamlessly with natural surroundings or modern structures alike.

oem galvanized iron welded wire mesh

Applications of Galvanized Iron Welded Wire Mesh

The applications of OEM galvanized iron welded wire mesh span across various industries, including

1. Construction In construction, welded wire mesh is widely used as reinforcing material for concrete. It enhances structural integrity, providing additional strength to slabs, walls, and foundations.

2. Agriculture Farmers utilize this mesh for fencing around fields and livestock enclosures, as it keeps animals secure and safe while allowing airflow and sunlight.

3. Gardening Gardeners frequently use galvanized wire mesh to create trellises, plant supports, and rabbit-proof fencing, protecting delicate plants from animals.

4. Industrial In industrial settings, welded wire mesh can function as safety barriers, shelving, and storage solutions. Its strength is crucial for supporting heavy loads without sagging or deforming.

5. Security The mesh is also used in security applications, including window grills and fencing, providing a robust deterrent against intrusions while still allowing visibility.

6. Transportation In the transportation sector, galvanized wire mesh is employed for manufacturing cargo nets and truck bed covers, ensuring that goods remain secure during transit.

Conclusion

The significance of OEM galvanized iron welded wire mesh cannot be overstated. Its combination of durability, cost-effectiveness, and versatility ensures that it remains a preferred choice across various sectors. As industries continue to evolve, the demand for high-quality materials that can withstand environmental stresses will only increase. By understanding the unique advantages and applications of galvanized wire mesh, contractors, farmers, and manufacturers can make informed decisions that enhance the efficacy and longevity of their projects. In essence, galvanized iron welded wire mesh is not just a material; it is a vital component that supports architectural innovation and agricultural efficiency.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025