Dec . 09, 2024 14:41 Back to list

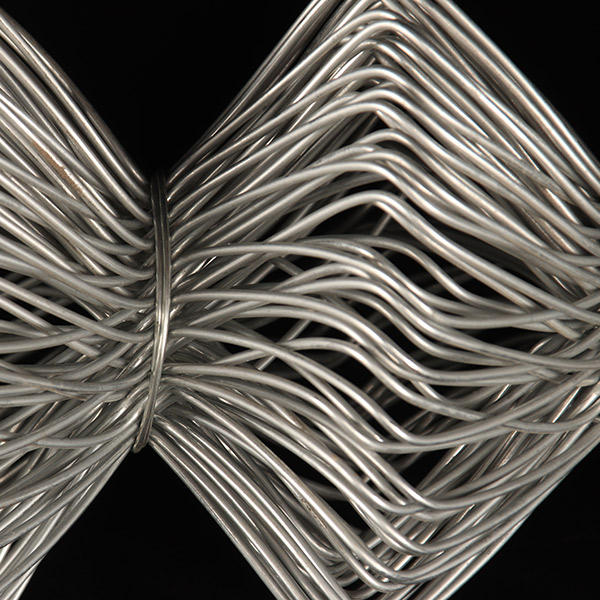

oem galvanized coated hanger wire

Understanding OEM Galvanized Coated Hanger Wire

In the world of industrial manufacturing, the term OEM (Original Equipment Manufacturer) often comes up when discussing products that are created to specific standards or specifications set by a company. One such product that exemplifies the importance of OEM standards is galvanized coated hanger wire. This article will explore the significance, applications, and characteristics of this essential item in various industries.

What is Galvanized Coated Hanger Wire?

Galvanized coated hanger wire is a type of wire that has undergone a galvanization process, which involves the application of a protective zinc coating. This coating serves as a barrier to prevent corrosion, significantly extending the lifespan of the wire, which is critical in many applications. Hanger wire is versatile and widely used in construction, electrical, HVAC (Heating, Ventilation, and Air Conditioning), and various manufacturing sectors.

The galvanized coating offers several advantages, including resistance to rust, enhanced durability, and suitability for outdoor applications. This makes galvanized coated hanger wire an ideal choice for projects that require reliable performance in challenging environments.

OEM Specifications and Customization

When it comes to OEM galvanized coated hanger wire, manufacturers are often required to meet specific criteria based on the needs of the customer. This could involve variations in wire diameter, tensile strength, coating thickness, and even the type of zinc used during the galvanization process.

Customization is key in many industries. Companies may need particular lengths, colors, or mechanical properties tailored to their operational requirements. For instance, businesses in the construction industry may require longer lengths to accommodate large-scale projects, while electrical applications might necessitate a finer gauge wire for better conductivity.

By working with OEM suppliers, businesses can ensure that the hanger wire they receive is not only high quality but also perfectly suited to their unique needs. Reliable suppliers often leverage advanced manufacturing technologies and strict quality control processes to produce wiring that adheres to industry standards.

Applications of Galvanized Coated Hanger Wire

Galvanized coated hanger wire is used in a myriad of applications across different industries

1. Construction In building projects, this type of wire is commonly used to suspend ceiling grids, support HVAC units, and secure pipes and conduits. Its strength and resistance to corrosion make it a go-to choice for construction contractors.

oem galvanized coated hanger wire

2. Electrical Electrical installations often benefit from galvanized hanger wire due to its non-corrosive properties and strength. It is used to hang electrical conduits and various other components, ensuring they remain securely in place, even in adverse conditions.

3. HVAC In heating, ventilation, and air conditioning systems, the need for durable and resistant materials is crucial. Galvanized coated hanger wire is utilized for ductwork and other attached features, allowing for effective and long-lasting system functionality.

4. Retail and Display Retailers often use galvanized hanger wire for creating various display racks and fixtures. Its strength allows for the display of heavy products, while its aesthetic appeal contributes to the overall design of the retail environment.

Benefits of Using OEM Galvanized Coated Hanger Wire

Opting for OEM galvanized coated hanger wire offers numerous benefits

1. Longevity The zinc coating provides excellent corrosion resistance, resulting in a longer lifespan for the wire, reducing the need for frequent replacements.

2. Cost-Effective Although initial costs may be higher, the durability and longevity of galvanization ultimately provide better value over time by reducing maintenance and replacement costs.

3. Versatility Its wide range of applications allows companies from various sectors to utilize the same product for multiple purposes, streamlining inventory and consumption.

4. Safety Using high-quality, OEM wires ensures compliance with safety and building regulations, which is essential in avoiding potential hazards in construction and installation processes.

Conclusion

In conclusion, OEM galvanized coated hanger wire is a quintessential component across multiple industries, offering durability, resistance to corrosion, and a range of customizable options. Whether in construction, electrical applications, or HVAC systems, its significance cannot be understated. Companies that prioritize quality and customization in their projects continue to rely on OEM suppliers to meet their specific needs, ensuring that they receive the best possible products tailored to their operational demands. As industries evolve and seek greater efficiency, the role of premium-quality OEM galvanized coated hanger wire will undoubtedly remain paramount.

-

Web Scraping-NIST|Data Extraction&Automation

NewsJul.23,2025

-

Web Scraping-NIST|Data Extraction&Automation

NewsJul.21,2025

-

Galvanized Steel Chain Link Fence - Anping County Puersen|Durable Security Solution&Cost-Effective Fencing

NewsJul.21,2025

-

Galvanized Steel Chain Link Fence - Anping County Puersen Hardware Wire Mesh Products Co.,Ltd

NewsJul.21,2025

-

Galvanized Steel Chain Link Fences-Anping County Puersen Hardware Wire Mesh Products Co.,Ltd|Durable Corrosion-Resistant Fencing&Cost-Effective Security Solutions

NewsJul.21,2025

-

Diamond Steel Grating - Anping County Puersen Hardware Wire Mesh Products Co., Ltd.|Durable Industrial Solutions&Customized Steel Grating

NewsJul.21,2025