Nov . 16, 2024 13:24 Back to list

oem galvanized binding wire

Understanding OEM Galvanized Binding Wire A Comprehensive Guide

Binding wire is an essential tool across various industries, serving versatile functions ranging from construction to agriculture. Among the different types of binding wire available, OEM (Original Equipment Manufacturer) galvanized binding wire stands out for its durability and versatility. This article delves into the features, applications, and benefits of OEM galvanized binding wire, shedding light on why it is a preferred choice for many professionals.

What is OEM Galvanized Binding Wire?

OEM galvanized binding wire is typically made from high-quality steel that is coated with a layer of zinc through a process known as galvanization. This coating protects the wire from corrosion, ensuring that it remains strong and intact even when exposed to harsh environmental conditions. The term OEM refers to products made to specifications set by another company, indicating that this type of wire can be customized to meet specific requirements.

Galvanization provides several advantages, including increased resistance to rust and longer service life. This factor is crucial for industries that face moisture exposure or severe weather conditions, making OEM galvanized binding wire an ideal choice for outdoor applications.

Features of OEM Galvanized Binding Wire

1. Corrosion Resistance The zinc coating effectively protects the wire from rust and corrosion, ensuring longevity and reliability.

3. Customizable Options As an OEM product, this binding wire can be manufactured to various specifications, including different diameters, lengths, and tensile strengths, catering to the specific needs of different industries.

4. Ease of Use The wire is lightweight and flexible, allowing for easy manipulation and installation. This quality is particularly beneficial in fast-paced work environments where efficiency is vital.

oem galvanized binding wire

5. Cost-Effective Despite its high-quality features, OEM galvanized binding wire is often competitively priced, offering a practical solution for businesses looking to maximize their investments.

Applications of OEM Galvanized Binding Wire

The versatility of OEM galvanized binding wire makes it suitable for a wide range of applications, including

- Construction In construction, the wire is used to bind rebar, secure scaffolding, and hold various structural elements together during the building process. Its strength and reliability ensure that structures are solidly anchored.

- Agriculture Farmers often utilize this binding wire for fencing, trellising plants, securing livestock, and various other agricultural tasks. The corrosion resistance is particularly important in outdoor environments exposed to moisture.

- Manufacturing Many manufacturing processes involve the bundling and strapping of products. OEM galvanized binding wire can securely hold items in place, ensuring safe storage and transportation.

- Crafting and DIY Projects For hobbyists and DIY enthusiasts, galvanized binding wire is an excellent tool for various crafting projects, from handmade jewelry to garden decorations.

Conclusion

In conclusion, OEM galvanized binding wire is a robust, reliable, and versatile solution for numerous applications across different sectors. Its unique features, such as corrosion resistance and high tensile strength, make it an indispensable tool in construction, agriculture, and manufacturing. By choosing OEM galvanized binding wire, professionals can ensure that they are investing in a product that not only meets their specific needs but also stands the test of time. Whether you are building a structure, securing a farm, or engaging in creative projects, OEM galvanized binding wire provides the strength and durability required to get the job done effectively.

-

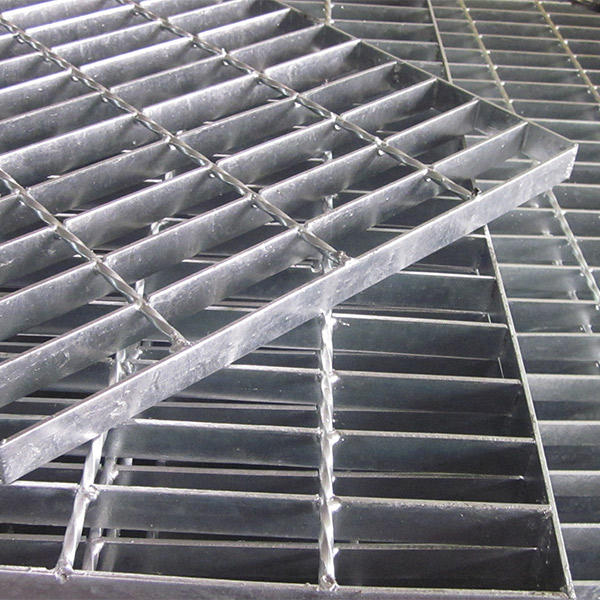

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025