Oct . 11, 2024 06:04 Back to list

Custom Electro Galvanized Wire Mesh Solutions for Various Applications and Industries

The Versatility and Importance of OEM Electro Galvanized Wire Mesh

In the realm of industrial applications, the significance of high-quality materials cannot be overstated. One such essential material is OEM electro galvanized wire mesh, which has garnered attention for its durability, versatility, and cost-effectiveness. This article delves into the characteristics, uses, and advantages of electro galvanized wire mesh, particularly focusing on its OEM production.

Understanding Electro Galvanization

Electro galvanization, also known as electroplating, involves the application of a zinc coating to steel wire through an electric current. This process offers a more uniform coating than traditional hot-dip galvanization and provides excellent protection against rust and corrosion, extending the life of the wire mesh. The zinc coating acts as a barrier, preventing moisture and environmental elements from coming into direct contact with the steel beneath.

Features of OEM Electro Galvanized Wire Mesh

OEM (Original Equipment Manufacturer) electro galvanized wire mesh is tailored to meet specific industry standards and client requirements. This customization may involve particular sizes, mesh densities, and zinc coating thicknesses, ensuring that products meet their intended application criteria. The notable features of OEM electro galvanized wire mesh include

1. Corrosion Resistance The zinc coating significantly extends the lifespan of the wire mesh, making it ideal for use in harsh environments. 2. Strength and Durability Constructed from high-quality steel, electro galvanized wire mesh provides the necessary strength to withstand various physical stresses. 3. Versatile Applications This type of wire mesh can be used across multiple industries, including construction, agriculture, and manufacturing.

4. Customizability With OEM services, companies can produce wire mesh that fits their unique specifications, ensuring efficiency and efficacy in its intended usage.

Applications of Electro Galvanized Wire Mesh

The applications of OEM electro galvanized wire mesh are extensive, ranging from industrial to commercial use

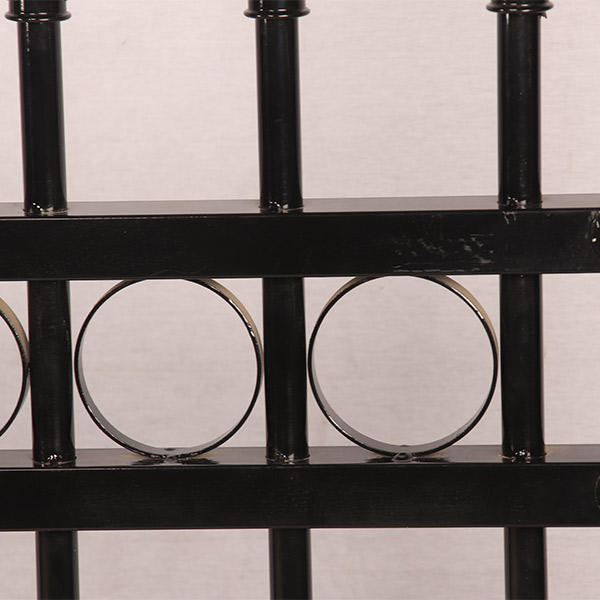

oem electro galvanized wire mesh

- Construction Used in projects as concrete reinforcement, providing added strength and structure. - Fencing Ideal for agricultural fencing, residential properties, and security barriers, offering both protection and visibility. - Animal Husbandry Utilized in animal pens and cages, ensuring safety while allowing for proper ventilation. - Filtration Systems Employed in various filtration applications, including water and air filtration systems, due to its strength and corrosion resistance.

Advantages of Using OEM Electro Galvanized Wire Mesh

There are several advantages associated with using OEM electro galvanized wire mesh

1. Cost-Effectiveness The initial investment is often lower when using electro galvanized wire mesh compared to other materials, especially when considering its long lifespan and reduced maintenance costs.

2. Low Environmental Impact The electro galvanization process is environmentally friendly, using less energy compared to hot-dip galvanization methods.

3. Enhanced Performance The uniform coating ensures consistent performance, reducing the chance of premature rusting and related failures.

4. Aesthetically Pleasing The smooth and shiny finish of electro galvanized wire mesh can also be aesthetically pleasing, making it suitable for visible applications.

Conclusion

In conclusion, OEM electro galvanized wire mesh stands as a testament to the advancements in material science, delivering strength, durability, and customization options necessary for various applications. Its ability to resist corrosion, combined with its versatility in different sectors, makes it an invaluable asset in both industrial and commercial contexts. As industries continue to seek durable and efficient materials, OEM electro galvanized wire mesh is likely to remain a top choice, fostering enhanced performance across numerous applications. Embracing the potential of this versatile material opens doors to innovation and reliability, underscoring its critical role in modern infrastructural development.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025