Nov . 24, 2024 18:27 Back to list

Customized Twisted Bar for Steel Grating with OEM Specifications and High Durability

The Role of OEM Cross Twisted Bars in Steel Grating Production

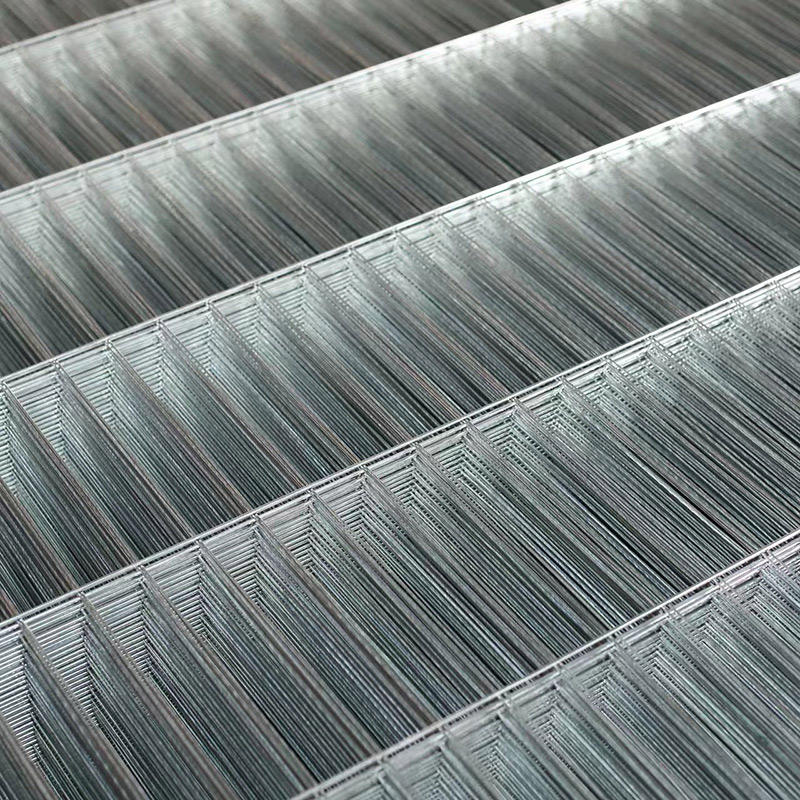

Steel grating has become an essential component in various industrial applications due to its durability, strength, and versatility. Among the numerous components that contribute to the structural integrity of steel grating, OEM (Original Equipment Manufacturer) cross twisted bars stand out as a fundamental element that enhances the performance and reliability of these products.

Understanding OEM Cross Twisted Bars

OEM cross twisted bars are specially designed steel bars that play a critical role in the construction of steel grating. These bars are manufactured following exact specifications provided by clients or market demands, making them tailored solutions for various applications. The term “cross twisted” refers to the unique structural design of the bars, which involves twisting steel rods together in a cross pattern. This design is crucial for ensuring maximum strength, stability, and resistance to deformation, particularly when subjected to heavy loads.

Advantages of Using Cross Twisted Bars in Steel Grating

1. Enhanced Load-Bearing Capacity One of the primary advantages of using OEM cross twisted bars is their ability to support heavy loads effectively. The twisted design increases the surface area of contact between the bars, thereby improving weight distribution and enhancing load-bearing performance. This is particularly important in industrial environments where heavy machinery and foot traffic are prevalent.

2. Increased Safety In industrial settings, safety is paramount. Cross twisted bars provide excellent slip resistance due to their unique texture and design, reducing the risk of accidents in workplaces. This makes them ideal for applications in factories, warehouses, and outdoor platforms where employees may encounter slippery conditions.

3. Corrosion Resistance Steel grating must often withstand various environmental conditions, including exposure to moisture and chemicals. OEM cross twisted bars can be treated with protective coatings that enhance their corrosion resistance, thus extending the lifespan of the grating and ensuring that it maintains its structural integrity over time.

oem cross twisted bar for steel grating

4. Customizability As OEM products, cross twisted bars can be custom-made to fit specific requirements and specifications. Manufacturers can tailor the dimensions, materials, and coatings according to the unique needs of different projects or clients. This level of customizability allows end-users to select the most suitable materials for their specific application, thereby enhancing their overall satisfaction with the product.

5. Cost-Effectiveness While the initial investment in high-quality OEM cross twisted bars may be higher than standard products, their durability and strength can lead to significant cost savings over time. Fewer replacements and reduced maintenance needs contribute to lower overall expenses in the long run.

Applications of OEM Cross Twisted Bars in Steel Grating

OEM cross twisted bars are utilized across various industries, including construction, oil and gas, transportation, and wastewater management. In construction, they are frequently used in walkways, platforms, and industrial flooring, offering robust support and safety features. In the oil and gas industry, these bars serve critical roles in grating systems for refineries and drilling platforms, where both weight and environmental factors must be carefully considered.

Moreover, in wastewater management facilities, the need for durable and corrosion-resistant materials is crucial. Steel grating featuring cross twisted bars can withstand harsh chemical environments, ensuring longevity and reliability in these applications.

Conclusion

In summary, OEM cross twisted bars represent an innovative and essential component in the manufacturing of steel grating. Their unique design enhances load-bearing capacity, provides slip resistance, and offers protection against corrosion. As industries continue to demand more durable and reliable materials, the role of OEM cross twisted bars in steel grating production will undoubtedly grow, contributing to safer and more efficient industrial environments. By understanding the benefits and applications of these specialized bars, manufacturers and end-users alike can make informed decisions that enhance productivity and safety across various sectors.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025