Oct . 05, 2024 03:36 Back to list

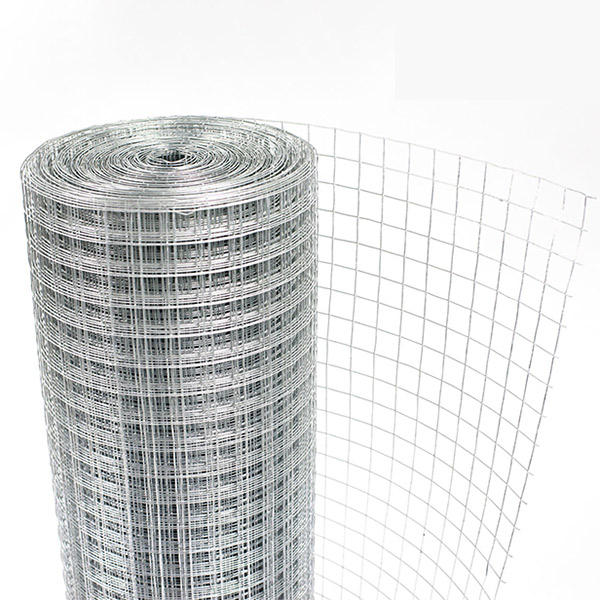

OEM Steel Bar Welded Mesh for Concrete Applications and Construction Solutions

The Importance of OEM Concrete Steel Bar Welded Mesh in Construction

In the ever-evolving field of construction, the materials used play a critical role in the durability and safety of structures. One such essential material is OEM concrete steel bar welded mesh, a component that has gained significant popularity due to its strength, versatility, and efficiency. This article explores the various aspects of welded mesh and its significance in modern construction practices.

OEM, or Original Equipment Manufacturer, refers to products manufactured by one company that are then branded and sold by another. In the context of concrete steel bar welded mesh, this indicates a quality assurance that the material meets specific industry standards. The mesh is created by welding together steel bars in a grid pattern, resulting in a robust framework that enhances the structural integrity of concrete elements.

One of the primary advantages of using OEM concrete steel bar welded mesh is its ability to improve tensile strength. Concrete is inherently strong in compression but weak in tension. The introduction of steel bars within the concrete mitigates this weakness, providing the tensile support necessary for structures like foundations, slabs, and beams. This combination allows for the construction of thinner slabs with increased load-bearing capabilities, ultimately leading to cost savings in materials and labor.

Welded mesh is also highly versatile and can be used in a variety of applications. From residential buildings to large-scale commercial structures, the use of welded mesh is prevalent across multiple sectors. It can be employed in floor slabs, walls, concrete pavements, and even in precast concrete products. This versatility, combined with the ease of installation, makes it a favorite among builders and contractors.

oem concrete steel bar welded mesh

Moreover, the use of welded mesh can significantly enhance the overall construction process. The prefabrication of mesh allows for faster assembly on-site, reducing labor time and minimizing mistakes that could arise from traditional methods of reinforcing concrete. This efficiency is particularly appealing in large projects where time is of the essence.

Another consideration is the cost-effectiveness of employing OEM concrete steel bar welded mesh. By reducing the quantity of concrete required and optimizing the design with high-strength welded mesh, contractors can achieve significant savings. Additionally, the durability and longevity of welded mesh structures mean lower maintenance costs over time, making it a wise investment for long-term projects.

In terms of environmental sustainability, the use of welded mesh can also contribute to greener building practices. By reducing material wastage and allowing for the recycling of steel, welded mesh aligns with the growing demand for sustainable construction solutions.

In conclusion, OEM concrete steel bar welded mesh represents a fundamental advancement in construction materials. It combines strength, versatility, and efficiency, making it an indispensable component in building modern structures. As the construction industry continues to innovate, the adoption of high-quality welded mesh will likely expand, setting new standards for durability and performance in concrete applications. This not only provides immediate benefits in terms of cost and time savings but also promotes sustainable practices that are crucial in today's environmentally conscious world.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025