Dec . 11, 2024 22:13 Back to list

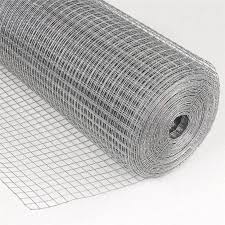

oem concrete reinforcing roll welded wire mesh

The Importance of OEM Concrete Reinforcing Roll Welded Wire Mesh

In the construction industry, the need for durable and reliable materials cannot be overstated. One of the essential components that contributes significantly to the strength and stability of concrete structures is the use of wire mesh, particularly OEM (Original Equipment Manufacturer) concrete reinforcing roll welded wire mesh. This specialized product plays a crucial role in enhancing the structural integrity of various concrete applications, from residential buildings to large-scale infrastructure projects.

What is OEM Concrete Reinforcing Roll Welded Wire Mesh?

OEM concrete reinforcing roll welded wire mesh is a type of welded wire reinforcement that is manufactured to meet specific standards and requirements set by original equipment manufacturers. This mesh is typically made from high-quality steel wires that are welded together at intersections, forming a rectangular grid. This design allows for uniform distribution of loads throughout the concrete, making it an ideal material for reinforcing slabs, walls, and other concrete elements. The mesh is produced in rolls, which facilitates easier handling and installation on job sites.

Benefits of Using OEM Welded Wire Mesh

1. Enhanced Structural Strength One of the primary benefits of using OEM concrete reinforcing mesh is its ability to significantly enhance the structural strength of concrete slabs. The welded wire mesh acts as a tension member, distributing loads evenly across the concrete surface. This helps to minimize cracking and ensures the longevity of the structure.

2. Cost-Effectiveness While some might consider the initial investment in welded wire mesh, the long-term savings it provides are undeniable. By reducing the likelihood of structural failures and the need for costly repairs, OEM wire mesh is a wise investment for any construction project.

3. Versatility This type of wire mesh can be used in a variety of applications, including floors, pavements, walls, and even precast concrete products. Its versatility makes it a favored choice among engineers and contractors who require adaptable solutions for different construction challenges.

oem concrete reinforcing roll welded wire mesh

4. Ease of Installation OEM concrete reinforcing roll welded wire mesh comes in convenient roll formats, making it easier to transport and deploy on-site. The mesh can be quickly unrolled and positioned, allowing for faster installation times and reduced labor costs.

5. Compliance with Standards Another noteworthy aspect of OEM products is their adherence to stringent quality standards. OEM welded wire mesh is manufactured to meet various industry certifications and guidelines, ensuring that it meets the requirements for safety and performance.

Applications of OEN Concrete Reinforcing Wire Mesh

The applications of OEM concrete reinforcing roll welded wire mesh are vast. It is commonly used in the construction of

- Residential Foundations Reinforcing concrete slabs and foundations to provide stability and reduce the risk of cracking. - Commercial Buildings Enhancing the strength of floors and walls in warehouses, retail spaces, and office buildings. - Roadways and Highways Used in the construction of pavements and overpasses, providing robustness to support vehicular loads. - Precast Concrete Elements Serving as fundamental reinforcement in precast products like panels and blocks, ensuring they meet strength requirements before being installed on-site.

Conclusion

In conclusion, OEM concrete reinforcing roll welded wire mesh is an indispensable material in modern construction. Its ability to enhance structural integrity while providing versatility, cost-effectiveness, and ease of installation makes it a go-to choice for various concrete applications. As the construction industry continues to evolve, the demand for high-quality reinforcing materials like OEM welded wire mesh will undoubtedly increase, ensuring safe and durable structures for years to come. Whether you are a builder, contractor, or engineer, investing in high-quality OEM wire mesh will pay dividends in the form of stronger, more resilient concrete constructions.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025