Nov . 30, 2024 22:18 Back to list

High-Quality OEM Cold Rolled Steel Bars for Versatile Applications and Durable Performance

Understanding OEM Cold Rolled Steel Bars An Overview

Cold rolled steel bars are essential components in various industries, known for their precision and durability. The term OEM stands for Original Equipment Manufacturer, indicating that these products are often made to meet specific needs of other brands or manufacturers. This article delves into the characteristics, production process, advantages, and applications of OEM cold rolled steel bars, as well as their significance in today’s manufacturing landscape.

Characteristics of Cold Rolled Steel Bars

Cold rolling involves processing steel at room temperature, which enhances its strength and surface finish. The resulting cold rolled steel bars are characterized by tighter tolerances, better dimensional accuracy, and improved surface quality compared to hot rolled alternatives. These bars are typically smoother and can be coated or treated for additional properties, making them suitable for a variety of applications where precision and aesthetics are crucial.

The composition of cold rolled steel often includes carbon, manganese, and other alloying elements that enhance its mechanical properties. The most common grades used in manufacturing cold rolled steel bars include low carbon steel for ductility and high carbon steel for strength. Each grade has unique features, making it necessary for manufacturers to select the appropriate type based on the end application's requirements.

The Production Process

The production of OEM cold rolled steel bars begins with a hot-rolled steel source, which is then cooled and processed through various stages. The initial step involves the breakdown of the hot rolled steel into manageable lengths. Subsequently, the steel is subjected to cold rolling, where it is passed through a series of rollers at room temperature to achieve the desired thickness and shape.

During this process, the steel undergoes significant deformation, which not only changes its shape but also refines its microstructure, enhancing its overall strength. Additional processes—including annealing, pickling, and surface finishing—may be employed to achieve specific mechanical properties or surface conditions. These finishing processes remove oxides and impurities while potentially adding protective coatings to ensure longevity in various environments.

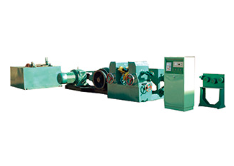

oem cold rolled steel bar

Advantages of OEM Cold Rolled Steel Bars

One of the primary benefits of using OEM cold rolled steel bars is their superior mechanical properties. The cold working process improves yield strength and tensile strength, making these bars an excellent choice for applications requiring high durability and resistance to wear and tear. Moreover, their improved surface finish reduces the need for additional machining or finishing processes, which can save time and costs in production.

Another significant advantage is the customization available through OEM suppliers. Manufacturers can specify dimensions, grades, and treatments tailored to their precise needs, allowing for enhanced compatibility with existing machinery or systems. This degree of customization is invaluable in industries where precision and reliability are paramount.

Applications in Various Industries

OEM cold rolled steel bars find applications in numerous sectors, including automotive, aerospace, construction, engineering, and manufacturing. In the automotive industry, these bars are often used for components like axles, shafts, and chassis parts where strength and performance are critical under various operational stresses. The aerospace sector also relies on cold rolled steel for structural components, emphasizing the need for weight reduction combined with durability.

In construction and engineering, these steel bars are favored for reinforcing structures, contributing to the strength and stability of buildings and bridges. Their versatility also extends to the manufacturing of machinery and equipment, where high-strength components are necessary to withstand demanding operational conditions.

Conclusion

In summary, OEM cold rolled steel bars are vital materials across diverse industries, offering a perfect blend of strength, precision, and customization. Their unique characteristics emerge from advanced production processes that optimize both their mechanical properties and surface qualities. As industries continue to evolve and demand higher performance materials, the importance of these steel bars will undoubtedly grow, solidifying their role in the future of manufacturing and engineering. Manufacturers looking to stay competitive should consider integrating OEM cold rolled steel bars into their production lines to benefit from their versatile applications and superior qualities.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025