Oct . 14, 2024 13:37 Back to list

oem black iron wire material

Exploring OEM Black Iron Wire Material Properties and Applications

When it comes to various manufacturing sectors, the choice of materials plays a pivotal role in determining both functionality and durability. One such material that has gained prominence is OEM black iron wire. This versatile material is used in a multitude of applications, ranging from construction to textile industries, due to its unique properties and advantages.

What is OEM Black Iron Wire?

OEM stands for Original Equipment Manufacturer, which indicates that the black iron wire is made specifically for use in products manufactured by other companies. This wire is typically made from low-carbon steel and is coated with a layer of iron, giving it a distinctive black appearance. The production of black iron wire involves drawing steel through dies to achieve a specific gauge, which can be customized according to client specifications.

Properties of OEM Black Iron Wire

1. Strength and Durability One of the standout qualities of black iron wire is its tensile strength. This durability makes it an ideal choice for applications that require sturdiness and resilience. The wire can withstand tension without breaking, making it suitable for various uses.

2. Corrosion Resistance While black iron wire is not as resistant to corrosion as galvanized wire, its natural oil coating provides a degree of protection against rust and environmental factors. This feature is crucial for applications in humid or wet conditions.

3. Flexibility Black iron wire is known for its malleability. It can be easily twisted, bent, and formed into different shapes without losing its integrity. This property is particularly valuable in applications such as crafting and construction, where intricate shapes and designs are critical.

oem black iron wire material

4. Cost-Effectiveness Compared to other wire materials, OEM black iron wire is relatively inexpensive, making it an economical option for manufacturers and consumers alike. This cost efficiency does not compromise quality, further enhancing its appeal.

Applications of OEM Black Iron Wire

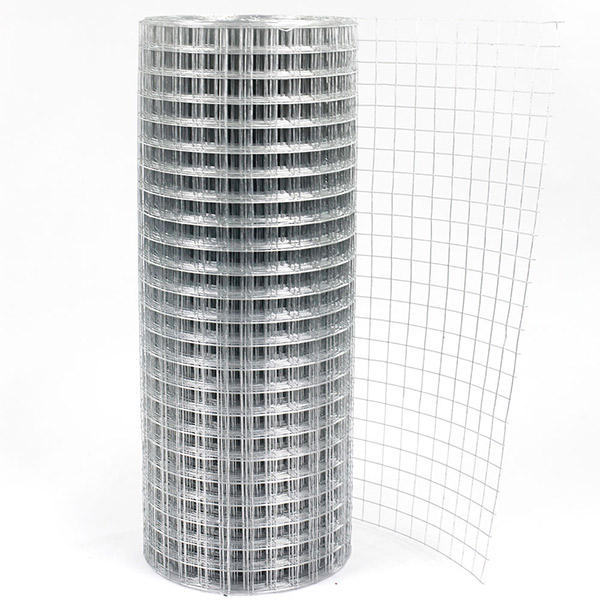

1. Construction In the construction industry, black iron wire is widely used for reinforcing concrete, supporting structures, and creating mesh frameworks. Its strength is indispensable in ensuring the stability and longevity of building projects.

2. Manufacturing OEM black iron wire serves various purposes in manufacturing environments. It can be used for creating springs, fasteners, and other components that require robust materials. Its versatility allows it to meet numerous design requirements.

3. Agriculture In the agricultural sector, black iron wire is often employed for fencing, trellises, and supporting plants. It provides the needed strength to withstand external pressures while remaining flexible enough for various agricultural applications.

4. Art and Craft Artists and crafters appreciate black iron wire for its aesthetic appeal and workability. It can be manipulated to create intricate designs in sculptures, jewelry, and other creative projects.

Conclusion

In conclusion, OEM black iron wire material presents a unique combination of strength, flexibility, and cost-effectiveness, making it an essential choice for various industries. Its wide range of applications—from construction and manufacturing to agriculture and artistry—illustrates its versatility and significance in today’s market. As industries continue to evolve, the demand for reliable and durable materials like OEM black iron wire will undoubtedly persist, further solidifying its role in modern manufacturing and crafting processes.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025