Nov . 24, 2024 13:24 Back to list

OEM Specifications for Black Annealed Wire Products and Their Applications

Understanding OEM Black Annealed Wire Specification

Black annealed wire, also known as black wire, is a type of iron wire that has undergone an annealing process to enhance its properties and make it more suitable for various applications. The term 'OEM' stands for Original Equipment Manufacturer, indicating that the wire is produced to meet specific standards outlined by a customer or industry requirement. This article will delve into the specifications of OEM black annealed wire, its characteristics, and its diverse applications.

Specifications of OEM Black Annealed Wire

1. Material Composition Black annealed wire is mainly composed of low carbon steel, typically with a carbon content of around 0.05% to 0.15%. The low carbon content contributes to the wire’s malleability and high ductility, making it easy to work with in various applications.

2. Manufacturing Process The production of black annealed wire involves several steps. First, steel wire is drawn to the desired diameter. Following this, the wire undergoes the annealing process, where it is heated and then cooled slowly to relieve internal stresses and enhance its mechanical properties. The resulting product is smooth and has a dark, black finish due to the oxidation during annealing.

3. Mechanical Properties OEM black annealed wire features excellent mechanical properties, including high tensile strength ranging from 300 to 600 MPa, and good elongation properties, which can exceed 10%. These properties make the wire ideal for different industrial applications where strength and flexibility are needed.

4. Surface Treatment The surface of the black annealed wire is free from any typical coatings, which gives it its characteristic black appearance. This surface finish is often preferred for applications that require secure bonding and adhesion, such as in the construction industry.

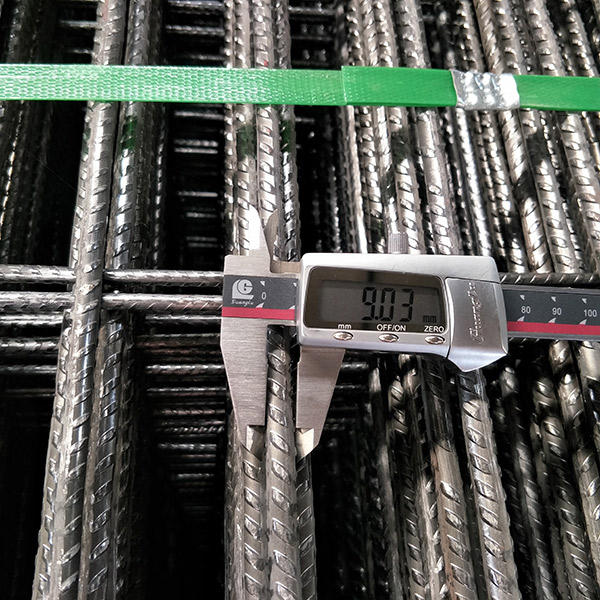

5. Diameter Range The diameter of black annealed wire varies, typically ranging from 0.30 mm to 6 mm. This range allows for a variety of uses, depending on the specific requirements of the application.

oem black annealed wire specification

Applications of OEM Black Annealed Wire

The versatility of black annealed wire has led to its use in numerous industries, including

1. Construction In the construction industry, black annealed wire is commonly used for tying rebar and other structural elements together. Its strength and flexibility make it an essential component for reinforcing concrete structures.

2. Fencing Black annealed wire is also widely used in fencing applications, providing secure boundaries for homes, farms, and industrial properties. Its robust nature prevents breakage and ensures longevity, making it ideal for outdoor environments.

3. Baling Wire The wire is frequently utilized to bind bales of hay, cotton, and other materials. It provides the necessary tensile strength to hold bales tightly, preventing them from falling apart during storage or transport.

4. Agriculture In the agricultural sector, black annealed wire serves multiple purposes, from electrifying fences to tying plants and crops. Its durability ensures minimal maintenance and consistent performance.

5. General Manufacturing The wire is also utilized in various manufacturing processes, such as the production of automotive parts, as well as in making hardware and tools due to its malleability and strength.

Conclusion

In conclusion, OEM black annealed wire is a highly versatile material that meets a range of specifications for various industrial and agricultural applications. With its excellent mechanical properties, affordability, and adaptability, it has become a staple component in many sectors. Understanding the specifications and applications of OEM black annealed wire helps industries select the right material for their specific needs and ensures reliability and performance in their projects. As the demand for efficient and durable materials continues to rise, black annealed wire will undoubtedly play a crucial role in supporting infrastructure and development across multiple industry sectors.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025