Nov . 11, 2024 23:42 Back to list

oem black annealed tie wire bwg12

Understanding OEM Black Annealed Tie Wire BWG 12 Applications and Benefits

In the world of industrial and construction materials, black annealed tie wire, specifically of gauge BWG 12, plays a crucial role. This versatile product is particularly favored in various applications due to its strength, flexibility, and adaptability. Understanding its properties, manufacturing processes, and practical applications can help businesses make informed decisions about their material needs.

What is Black Annealed Tie Wire?

Black annealed tie wire is a type of steel wire that has undergone an annealing process to enhance its properties. The black refers to the wire's surface, which is coated with a layer of iron oxide from the manufacturing process, giving it a distinctive dark appearance. The annealing process itself involves heating and then cooling the wire, which results in a softer and more ductile product. This enhancement renders the wire easier to work with, ensuring that it can be bent and twisted without fracturing.

Significance of BWG 12

The term BWG stands for Birmingham Wire Gauge, a standardized measurement system used to specify wire thickness. BWG 12 corresponds to a wire diameter of approximately 2.64 mm or 0.104 inches. This gauge is particularly beneficial for applications requiring a balance between strength and flexibility. BWG 12 black annealed tie wire is robust enough to handle heavy-duty tasks yet pliable for easy manipulation during installation.

Manufacturing Process

The production of black annealed tie wire involves several stages. Initially, low-carbon steel wire is drawn to the desired gauge. The wire is then subjected to the annealing process, where it is heated in a controlled environment, influencing its mechanical properties. After cooling, the wire is often coated with oil or undergoes additional surface treatments to enhance corrosion resistance and improve handling.

Key Applications

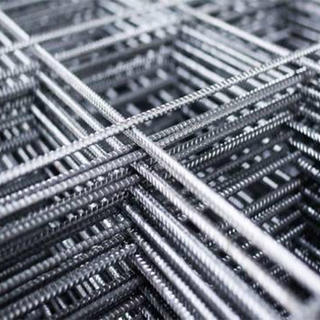

1. Construction and Building Black annealed tie wire is predominantly used in the construction industry. It serves as a versatile tool for tying rebar in concrete formations. The flexibility of BWG 12 tie wire allows contractors to secure steel reinforcement bars effectively, which is vital for ensuring structural integrity in concrete structures.

oem black annealed tie wire bwg12

2. Packaging and Binding Another common application is in packaging and binding materials. The wire is ideal for bundling products, securing various items together, and even in the horticultural sector for tying plants. Its strength allows it to hold significant weight, making it a reliable choice for these tasks.

3. Automotive Industry In automotive manufacturing, black annealed wire can be used for various purposes, such as creating springs, hooks, and other components that require bendability and strength.

4. General Fabrication Manufacturers often utilize black annealed tie wire in general fabrication processes. It serves as a reliable tool in creating custom shapes and components where persistent properties and stability are required.

Benefits of Using BWG 12 Tie Wire

1. Durability The low-carbon steel used in black annealed tie wire provides excellent durability, making it suitable for various environments, including those exposed to moisture and other elements.

2. Ease of Use The pliability of BWG 12 makes it easy to work with, whether manually or with tools, allowing for efficient installations and applications.

3. Cost-Effectiveness Compared to other reinforcing materials, BWG 12 black annealed tie wire is relatively inexpensive, providing an economical solution without compromising quality.

4. Versatility Its applications are vast, catering to numerous industries—from construction to automotive, making it a favorite choice across different sectors.

Conclusion

In summary, OEM black annealed tie wire, specifically BWG 12, is an invaluable material that meets the demands of various industries. Its strength, flexibility, and adaptability make it an essential tool in construction, packaging, automotive manufacturing, and general fabrication. Understanding its properties and applications not only helps manufacturers and contractors make informed decisions but also ensures that projects are executed efficiently and effectively. As industries continue to evolve, the importance of reliable materials like black annealed tie wire remains steadfast, making it a cornerstone in modern manufacturing and construction practices.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025