Oct . 04, 2024 16:30 Back to list

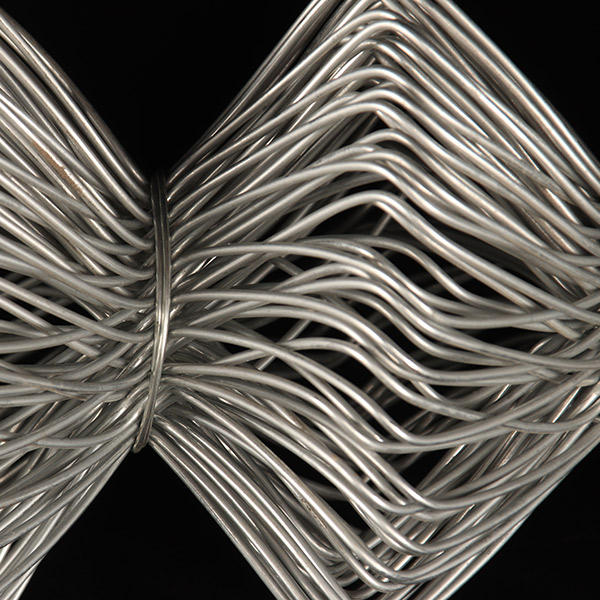

oem binding iron wire

OEM Binding Iron Wire The Backbone of Custom Manufacturing

In the realm of manufacturing and industrial applications, the importance of high-quality binding materials cannot be overstated. Among these, OEM (Original Equipment Manufacturer) binding iron wire has gained considerable attention due to its versatility and reliability in various sectors. This article explores the features, applications, and benefits of using OEM binding iron wire in custom manufacturing processes.

OEM Binding Iron Wire The Backbone of Custom Manufacturing

One of the most significant advantages of OEM binding iron wire is its adaptability. It can be produced in various diameters, strengths, and coatings, making it suitable for a broad range of applications. Industries such as construction, agriculture, and manufacturing utilize these wires extensively. For instance, in the agricultural sector, binding wire is crucial for securing plants and crops, ensuring optimal growth and stability. In construction, OEM binding iron wire is often used to tie rebar together, providing essential support and structure in concrete projects.

oem binding iron wire

Furthermore, the cost-effectiveness of OEM binding iron wire makes it an attractive choice for manufacturers. Custom solutions can be developed to meet specific needs without significantly increasing production costs. By opting for OEM products, companies can also benefit from lower inventory costs, as they can order wire tailored to their unique applications rather than relying on generic solutions.

The manufacturing process of OEM binding iron wire involves various stages, including drawing, annealing, and coating, which contribute to the wire’s mechanical properties and corrosion resistance. By subjecting the wire to controlled heat treatment processes, manufacturers can enhance its strength and ductility, ensuring that it meets the demanding requirements of its intended applications. Additionally, coating options like zinc plating help to improve corrosion resistance, extending the wire's lifespan, especially in harsh environmental conditions.

In conclusion, OEM binding iron wire serves as an essential component in custom manufacturing across multiple industries. Its durability, versatility, and cost-effectiveness make it an invaluable resource for manufacturers looking to improve their products and operational efficiency. As industries continue to evolve and demand specialized solutions, the role of OEM binding iron wire in facilitating innovative manufacturing processes will only grow in significance. By investing in high-quality binding wire, manufacturers can ensure the integrity of their projects and support the seamless flow of their production lines.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025