Oct . 19, 2024 03:11 Back to list

oem arame recozido torcido

The Innovative World of OEM Twisted Ropes A Comprehensive Overview

In the ever-evolving landscape of manufacturing, Original Equipment Manufacturer (OEM) products play a vital role across various sectors. One fascinating niche within this field is the production of twisted ropes, specifically those made from OEM specifications, commonly referred to as OEM arame recozido torcido. This concept, rooted in both innovation and functionality, reflects the synergy between material science and manufacturing processes, delivering products that meet unique customer demands.

The Science Behind Twisted Ropes

Twisted ropes are typically made from various materials, including natural fibers, synthetic fibers, or metal. The term arame recozido refers to a type of wire that has undergone a particular heat treatment process, enhancing its properties such as strength and flexibility. When twisted, these materials create a rope that is not only strong but also adaptable for various applications. The unique twisting process provides additional tensile strength and makes the rope more resistant to wear and tear, which is essential for many industrial applications.

Applications of OEM Twisted Ropes

The applications for OEM twisted ropes are extensive and diverse. In construction, these ropes serve as essential components for lifting and securing heavy materials. Their high tensile strength ensures safety and reliability, crucial factors when working at heights or with heavy loads. Additionally, in maritime industries, these ropes are used for mooring, towing, and securing vessels due to their durability against saltwater corrosion.

Moreover, OEM twisted ropes are increasingly finding their way into specialized sectors such as the automotive and aerospace industries. In these fields, the need for lightweight yet strong materials drives innovation. Twisted ropes made from advanced composites or metal alloys provide the necessary strength without adding undue weight, thereby enhancing performance and fuel efficiency.

Customization and OEM Partnerships

oem arame recozido torcido

One of the significant advantages of OEM products is the ability to customize them according to the specific needs of a client. Companies specializing in the production of OEM twisted ropes often collaborate closely with their customers, tailoring the ropes in terms of length, diameter, material composition, and even the degree of twist. Such customization ensures that the end product perfectly matches the operational requirements and environmental conditions of the intended application.

Building strong partnerships between manufacturers and clients is crucial. By understanding the exact specifications required, manufacturers can optimize production processes, ensuring that the finished product aligns with the client’s needs and expectations. This collaborative approach fosters innovation, enabling the creation of bespoke solutions that enhance operational efficiency.

The Future of OEM Twisted Ropes

As technology continues to advance, the future of OEM twisted ropes looks promising. Innovations such as smart materials and advanced manufacturing techniques, including 3D printing, could revolutionize how these ropes are produced and utilized. For instance, integrating sensors into the rope could provide real-time data on stress levels, wear, and environmental conditions, leading to smarter and safer operations.

Sustainability is another emerging trend within the OEM ropes market. As industries become more environmentally conscious, the demand for eco-friendly materials and production processes is on the rise. Manufacturers are exploring the use of biodegradable fibers and recycled materials, paving the way for a more sustainable approach to twisted rope production.

Conclusion

In conclusion, OEM twisted ropes stand at the intersection of innovation, customization, and practicality. Their diverse applications across various industries highlight their importance in modern manufacturing. As technology progresses and the demand for tailored, high-performance materials continues to grow, the future of OEM twisted ropes promises exciting developments that will undoubtedly shape the industry. Whether for construction, maritime, or specialized applications, these ropes are set to remain a cornerstone of reliability and functionality.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

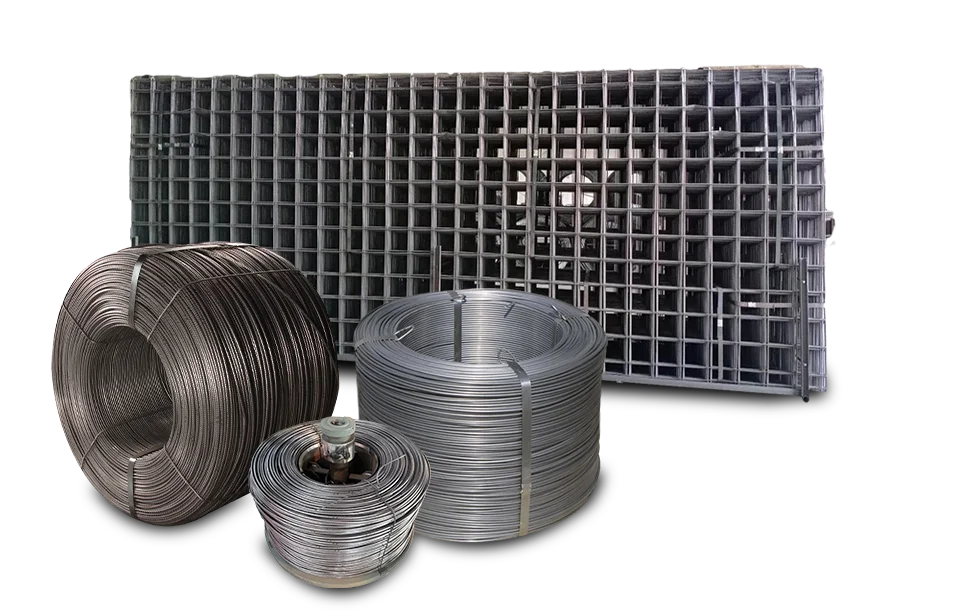

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025