Dec . 10, 2024 22:49 Back to list

OEM 208mm Cold Drawn Wire Specifications and Applications Explained in Detail

The Advantages of OEM 8mm Cold Drawn Wire in Modern Manufacturing

In the contemporary manufacturing landscape, the significance of precision-engineered materials cannot be overstated. Among these materials, OEM (Original Equipment Manufacturer) 8mm cold drawn wire has emerged as a critical component in various industrial applications. This article delves into the characteristics, benefits, and applications of 8mm cold drawn wire, highlighting its role in enhancing product quality and operational efficiency.

Understanding Cold Drawing

Cold drawing is a manufacturing process in which wire is pulled through a die to reduce its diameter while increasing its tensile strength. The process typically occurs at room temperature, which is why it is termed cold drawing. This method of wire production not only shapes the material but also refines its mechanical properties, producing a wire that is more robust and durable than its hot-rolled counterparts.

Key Characteristics of 8mm Cold Drawn Wire

1. Uniform Diameter One of the primary benefits of cold drawn wire is its consistent diameter. The precision achieved during the drawing process ensures that the wire meets specific size requirements, which is crucial for applications where uniformity is essential.

2. Increased Strength Cold drawing enhances the tensile strength of the wire. The process aligns the grain structure of the metal, resulting in a stronger and more resilient material. This makes 8mm cold drawn wire suitable for demanding applications where high strength is required.

3. Improved Surface Finish The cold drawing process also contributes to a smoother surface finish compared to other wire types. A smooth surface reduces friction when the wire is used in various applications and enhances the overall aesthetic quality of the end products.

4. Versatility OEM 8mm cold drawn wire can be produced from various metals, including carbon steel, stainless steel, and alloy compositions. This versatility allows manufacturers to select the right type of wire based on their specific needs, ensuring that the end product meets desired performance standards.

oem 8mm cold drawn wire

Applications of 8mm Cold Drawn Wire

OEM 8mm cold drawn wire is used in a myriad of applications across different industries

- Construction Industry In the construction sector, 8mm cold drawn wire is often used in the manufacturing of reinforced concrete and pre-stressed concrete products. Its high tensile strength makes it ideal for supporting structures.

- Automotive Manufacturing In the automotive industry, cold drawn wire is utilized to produce components like springs, wires, and various fixtures. The durability and reliability of the wire make it a preferred choice for parts that undergo significant stress.

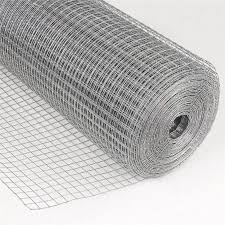

- Manufacturing of Fencing and Grating The strength and flexibility of the wire make it suitable for fencing applications, including agricultural and industrial fencing, as well as grating used in various structures.

- Electrical Applications In electrical engineering, 8mm cold drawn wire serves as a fundamental material for producing electrical conductors and connections. Its conductivity and strength ensure efficient and reliable connections.

Conclusion

In summary, OEM 8mm cold drawn wire is a vital material in modern manufacturing, characterized by its uniform diameter, increased strength, improved surface finish, and versatility. Its applications across various industries demonstrate its importance in producing high-quality, reliable products. As manufacturers continue to seek solutions that enhance performance and efficiency, the significance of cold drawn wire will only continue to grow, solidifying its role as a cornerstone in the manufacturing process. Investing in high-quality 8mm cold drawn wire can lead to substantial long-term benefits, making it an invaluable asset for any industrial operator.

-

Welded Wire Mesh for Industry Factory - Anping County Puersen Hardware Wire Mesh Products Co., Ltd.

NewsAug.29,2025

-

Welded Wire Mesh for Industry Factory | Durable & Cost-Effective Solutions

NewsAug.29,2025

-

Durable Welded Wire Mesh for Industry Factory | Custom Solutions

NewsAug.27,2025

-

Durable Welded Wire Mesh for Industry Factory - High Quality

NewsAug.26,2025

-

Leading Galvanized Steel Fence Factory | Durable & Secure Fencing

NewsAug.24,2025

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025