Nov . 24, 2024 16:53 Back to list

OEM Welded Wire Mesh with 6mm and 8mm Steel Bar for Construction Applications

The Importance of OEM 6mm and 8mm Steel Bar Welded Wire Mesh in Construction

In the ever-evolving world of construction materials, the demand for durable and reliable structural support has led to the increased use of welded wire mesh. Among the various specifications available, OEM (Original Equipment Manufacturer) 6mm and 8mm steel bar welded wire mesh stand out as essential components for numerous construction applications. This article will explore the characteristics, benefits, and applications of this specific type of welded wire mesh.

Characteristics of 6mm and 8mm Steel Bar Welded Wire Mesh

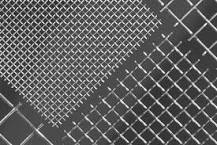

Welded wire mesh is made from pre-cut steel bars that are welded together to form a grid. The bars come in different diameters, with 6mm and 8mm being popular choices due to their balance of strength and flexibility. The mesh is manufactured at various intervals, creating a grid pattern that can be tailored to specific project requirements.

The welding process used in manufacturing this mesh is crucial. It ensures that each intersection between the bars is fused together, creating a robust structure capable of withstanding various loads and stresses. The meshes are typically galvanized or coated to resist corrosion, further enhancing their longevity and performance.

Benefits of Using OEM Welded Wire Mesh

1. Strength and Durability The primary advantage of using 6mm and 8mm steel bar welded wire mesh lies in its strength. These meshes are designed to bear heavy loads, making them ideal for reinforced concrete structures. Their durability ensures that they can endure various environmental factors, including moisture and temperature changes, which might weaken lesser materials over time.

2. Versatility This type of welded wire mesh is highly versatile, suitable for a variety of construction applications. It can be used in foundations, walls, slabs, and even in decorative applications. The ability to customize the size and grid spacing makes it an attractive choice for architects and builders looking to meet specific design requirements.

3. Cost-Effectiveness By integrating 6mm and 8mm welded wire mesh into their designs, builders can achieve substantial cost savings. The mesh reduces the amount of concrete needed in structures, as it provides additional support without adding significant weight. Additionally, the longevity of the product means that it requires less frequent replacement or repair.

oem 6mm 8mm steel bar welded wire mesh

4. Ease of Installation Welded wire mesh is relatively easy to install. It can be cut and shaped to fit various forms and sizes, allowing for quick and efficient deployment on-site. This ease of handling not only speeds up the construction process but also minimizes labor costs.

5. Safety and Stability Using welded wire mesh enhances the overall safety of construction projects. The grid pattern contributes to uniform load distribution, which helps prevent cracking and structural failure, thereby increasing the longevity of the construction.

Applications of Welded Wire Mesh in Construction

The applications of OEM 6mm and 8mm steel bar welded wire mesh in construction are numerous and diverse

- Reinforced Concrete Slabs When used within concrete slabs, welded wire mesh helps distribute stress evenly and prevents cracking over time, ensuring the floor's integrity. - Fences and Barriers Due to its strength, welded wire mesh is often employed in the construction of fences and barriers, providing security without obstructing visibility.

- Retaining Walls Welded wire mesh is frequently used in constructs that need to hold back soil, ensuring stability and safety in landscaping projects.

- Road and Pavement Construction In road building, welded wire mesh offers additional support in asphalt and concrete roads, enhancing their durability and lifespan over years of heavy traffic.

Conclusion

In summary, OEM 6mm and 8mm steel bar welded wire mesh represents a critical component in modern construction. Its strength, versatility, cost-effectiveness, and ease of installation make it an invaluable asset for builders and architects alike. As construction methods evolve and the focus on efficient, durable materials increases, the importance of high-quality welded wire mesh will continue to grow, paving the way for robust and long-lasting structures. Whether you are a builder, architect, or engineer, understanding the benefits and applications of this innovative material will undoubtedly contribute to the success of your next construction project.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025