Nov . 07, 2024 09:08 Back to list

OEM 4mm Cold Drawn Wire for Various Applications and Industries

Understanding OEM 4mm Cold Drawn Wire Applications and Benefits

In the manufacturing and construction industries, the demand for high-quality materials that meet specific standards is constantly on the rise. One such material that has gained significant attention is the OEM (Original Equipment Manufacturer) 4mm cold drawn wire. This specialized wire is widely used for various applications due to its unique properties, which are attributed to the cold drawing process.

Cold drawing is a technique that involves pulling a metal wire through a die to reduce its diameter and increase its length. This process improves the wire’s mechanical properties by enhancing its tensile strength and hardness. When it comes to 4mm cold drawn wire, manufacturers can achieve precise diameters whilst ensuring superior surface finish and consistency. The resulting wire exhibits excellent dimensional accuracy, making it ideal for applications that require tight tolerances.

Applications of 4mm Cold Drawn Wire

OEM 4mm cold drawn wire is versatile and finds applications across several industries. Some of the most common uses include

1. Automotive Components The automotive industry relies heavily on cold drawn wire for the production of various components, such as spring wires, coil springs, and wire forms. The high tensile strength of cold drawn wire ensures that parts can withstand the rigorous demands of automotive applications.

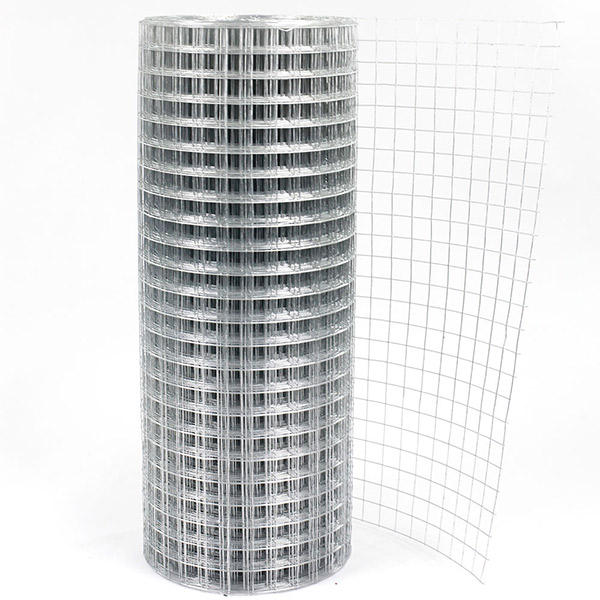

2. Construction and Infrastructure Cold drawn wire is also utilized in the construction sector, particularly in reinforced concrete structures. Steel reinforcement bars and wire mesh made from cold drawn wire provide enhanced stability and strength to buildings and bridges.

3. Manufacturing of Fasteners Fasteners such as bolts, nuts, and screws are often produced using 4mm cold drawn wire. The high strength and uniformity of the wire ensure that these fasteners can handle significant loads without deforming.

4. Electrical Applications In the electrical industry, cold drawn wire is used for making electrical connectors and cable strands due to its excellent conductivity and reliability. Moreover, the structural characteristics of cold drawn wire enhance the performance of electrical components.

oem 4mm cold drawn wire

Benefits of Using OEM 4mm Cold Drawn Wire

Opting for OEM 4mm cold drawn wire presents several advantages

1. Improved Mechanical Properties The cold drawing process significantly improves the strength and toughness of the wire, making it suitable for heavy-duty applications.

2. Precision and Uniformity OEM manufacturers adhere to strict quality control standards when producing cold drawn wire. As a result, users benefit from high precision and uniform diameter, which is crucial for applications requiring component interoperability.

3. Cost-Effectiveness Despite the advanced production techniques involved, cold drawn wire can be produced at competitive prices, making it a cost-effective solution for manufacturers looking to maintain quality without inflating their budgets.

4. Customization Options OEM suppliers often offer customization options for cold drawn wire, allowing companies to tailor specifications such as length, finish, and tolerances to meet specific project requirements.

5. Environmentally Friendly Processes Cold drawing is generally considered an environmentally friendly process since it does not require extensive heat treatment, minimizing energy consumption and waste production.

Conclusion

In summary, OEM 4mm cold drawn wire is an essential material in several industries due to its impressive mechanical properties and versatility. As businesses strive for more efficient and durable components, the reliance on high-quality materials like cold drawn wire will undoubtedly continue to grow. Organizations looking to invest in their manufacturing processes would do well to consider the benefits and applications of OEM 4mm cold drawn wire, ensuring they remain competitive in a market that increasingly values both quality and cost-effectiveness. Whether it’s for automotive, construction, or electrical applications, the advantages of cold drawn wire are clear, paving the way for innovation and enhanced performance across various sectors.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025