Oct . 22, 2024 09:14 Back to list

High-Quality Gauge Welded Wire Mesh for OEM Applications in 2012 Standard

Understanding OEM 2012 Gauge Welded Wire Mesh Applications and Benefits

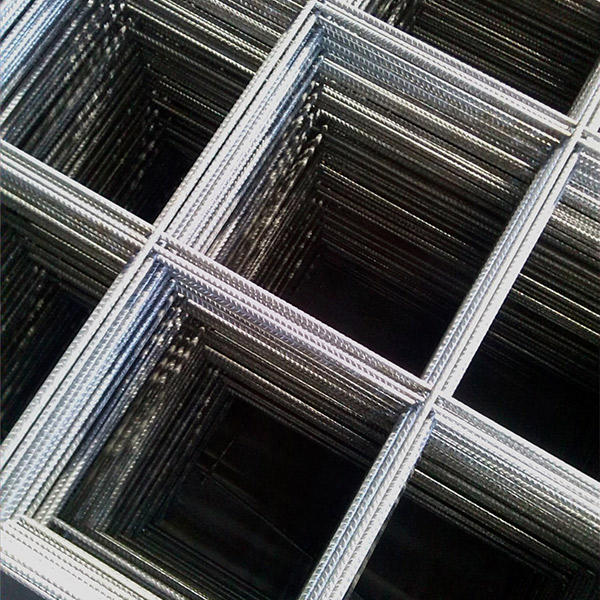

Welded wire mesh has long been a staple in various industries, providing a flexible and durable solution for many applications. Among the myriad types of welded wire mesh, the OEM 2012 gauge welded wire mesh has gained recognition due to its unique characteristics and adaptability. This article delves into the specifics of OEM 2012 gauge welded wire mesh, exploring its features, applications, and advantages.

Definition and Features

OEM, or Original Equipment Manufacturer, refers to the production of components that are used in larger assemblies, often with a focus on quality and compliance with specific standards. The 2012 gauge represents the thickness of the wire used in the mesh, with gauge typically referring to the weight of the wire per unit length. In this case, a 2012 gauge wire would be thinner than lower gauge numbers, providing a balance of strength and flexibility.

Welded wire mesh is formed by welding together horizontal and vertical wires at their intersections, creating a grid of openings. The quality of the weld, wire thickness, and spacing between wires are crucial factors that determine the mesh's overall strength and applicability.

Common Applications

OEM 2012 gauge welded wire mesh is versatile and used across various industries. Some of its common applications include

1. Construction Industry The construction sector frequently utilizes welded wire mesh as reinforcement in concrete slabs, walls, and even roofing. The mesh provides additional tensile strength, ensuring that structures have better durability and load-bearing capabilities. 2. Agricultural Uses Farmers and agriculturalists use welded wire mesh for fencing, creating enclosures for livestock, and protecting crops from pests. Its resilience ensures longevity even in outdoor environments.

3. Industrial Applications In industrial settings, OEM 2012 gauge welded wire mesh is essential for creating security cages, storage racks, and safety barriers. It facilitates effective organization and protects equipment and goods from unauthorized access or damage.

4. Architectural Design More recently, welded wire mesh has found its way into modern architectural designs, offering aesthetic appeal alongside practicality. It is used in facades, interior partitions, and decorative elements, contributing to both functionality and design vision.

5. DIY Projects Hobbyists and DIY enthusiasts appreciate the versatility of this material for various projects, from gardening frames to decorative art installations.

oem 12 gauge welded wire mesh

Advantages of OEM 2012 Gauge Welded Wire Mesh

The OEM 2012 gauge welded wire mesh stands out due to several significant benefits

1. Strength and Durability The construction of welded mesh provides exceptional strength and resistance to pulling and bending forces, making it ideal for heavy-duty applications.

2. Customization OEM products often allow for customization in terms of dimensions, wire diameter, and mesh openings. This flexibility enables users to tailor the product to their specific needs.

3. Cost-Effectiveness While higher-grade materials may offer better strength, the 2012 gauge welded wire mesh provides a good balance of economy and performance, making it an attractive option for budget-conscious projects.

4. Ease of Installation Welded wire mesh is generally lightweight and easy to handle, facilitating straightforward installation. This trait is particularly advantageous for large-scale projects where efficiency is essential.

5. Longevity When properly installed and maintained, welded wire mesh can last for years, reducing the need for frequent replacements and repairs.

6. Versatile Applications As outlined, this type of mesh finds applications across many sectors, which adds to its utility for various consumers, from industrial manufacturers to home gardeners.

Conclusion

In summary, OEM 2012 gauge welded wire mesh represents a highly functional and adaptable solution for a wide array of applications. Its strength, durability, and cost-effectiveness make it an attractive choice in construction, agriculture, and beyond. As industries continue to evolve, so too will the use of specialized welded wire mesh products, but the foundational advantages of the OEM 2012 gauge will likely always keep it in demand. Whether you're looking to reinforce structures, secure perimeters, or innovate in design, this welded wire mesh option presents a reliable and versatile choice.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025