Nov . 24, 2024 16:18 Back to list

High-Precision 10mm Cold Drawn Wire Manufacturing for OEM Applications

Understanding OEM 10mm Cold Drawn Wire Applications and Advantages

Cold drawn wire, particularly OEM 10mm variants, has garnered significant attention in the manufacturing and construction industries due to its superior properties and versatility. This article aims to delve into the characteristics, applications, and advantages of OEM 10mm cold drawn wire, highlighting why it is a preferred choice for various applications.

What is Cold Drawn Wire?

Cold drawn wire is produced through a process that involves pulling metal rods through a series of dies at room temperature. This technique significantly enhances the wire's mechanical properties, including strength, ductility, and surface finish. The cold drawing process removes any impurities and imperfections from the surface, resulting in a smooth finish that's essential for many applications in demanding environments.

The Significance of the 10mm Diameter

The 10mm diameter makes this type of wire particularly suitable for applications where robust mechanical properties are required. Such thickness accommodates various industrial requirements while remaining easy to handle. From construction reinforcements to specialized manufacturing processes, 10mm cold drawn wire serves diverse needs across different sectors.

Applications of OEM 10mm Cold Drawn Wire

1. Construction Industry One of the primary applications of 10mm cold drawn wire is in the construction sector, particularly in reinforcement for concrete structures. Its tensile strength and durability make it an ideal choice for scaffolding, bar tying, and as anchoring systems in various building projects.

2. Automotive Manufacturing The automotive industry relies on OEM 10mm cold drawn wire for various components, such as springs, suspension parts, and frames. The wire's high strength-to-weight ratio ensures reliability and safety in vehicles, making it a critical material in automotive design and manufacturing.

3. Electronics Industry In the electronics sector, this type of wire is used in components like electrical connectors and wiring harnesses. The excellent conductivity and strength of cold drawn wire make it suitable for high-performance electrical applications.

oem 10 mm cold drawn wire

4. Machinery and Equipment OEM 10mm cold drawn wire also finds applications in the production of machinery and industrial equipment. Its resilience under harsh conditions allows it to be used in manufacturing high-stress components, enhancing the durability and lifespan of the machinery.

5. Artistic and Craft Projects Beyond industrial applications, cold drawn wire can also be utilized in art and craft projects. Its malleability allows artists to bend and shape it into intricate designs, making it a favorite among sculptors and artisans.

Advantages of OEM 10mm Cold Drawn Wire

1. Improved Mechanical Properties The cold drawing process enhances tensile strength, yield strength, and overall stability, making it less prone to deformation under stress.

2. Versatile Applications With its balanced strength and flexibility, this wire can be used across various sectors, from construction to automotive, showcasing its adaptability.

3. Cost-Effectiveness Although cold drawn wire may have a higher initial production cost than traditional wire, its longevity and superior performance traits can lead to lower replacement and maintenance costs in the long run.

4. Enhanced Surface Finish The smooth surface achieved through cold drawing reduces friction, thereby increasing the efficiency of applications where movement or contact occurs.

5. Environmental Considerations OEM manufacturers are now more focused on sustainable practices, producing cold drawn wires with less waste and a reduced ecological footprint.

Conclusion

OEM 10mm cold drawn wire represents a critical material in modern manufacturing and construction, providing unparalleled strength, versatility, and performance. As industries continue to evolve and embrace new technologies, the demand for high-quality cold drawn wire is likely to grow, making it an essential component in the quest for innovative and durable solutions.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

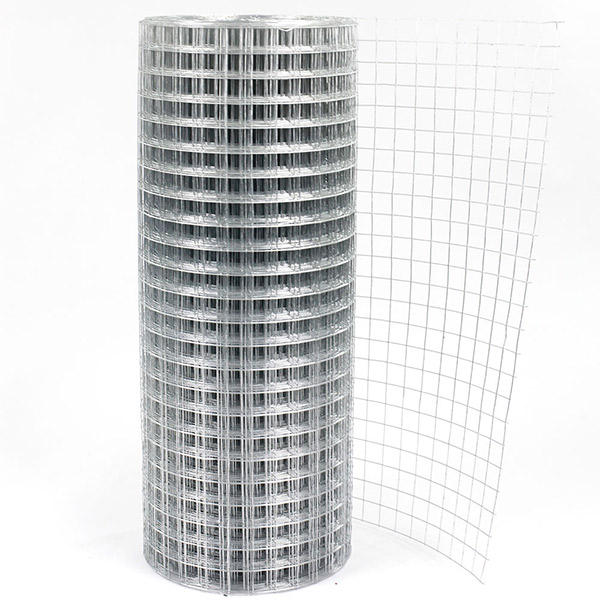

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025