Sep . 04, 2024 03:48 Back to list

oem sl52 sl62 sl72 sl82 reinforcement

Understanding OEM SL Series Reinforcement SL52, SL62, SL72, SL82

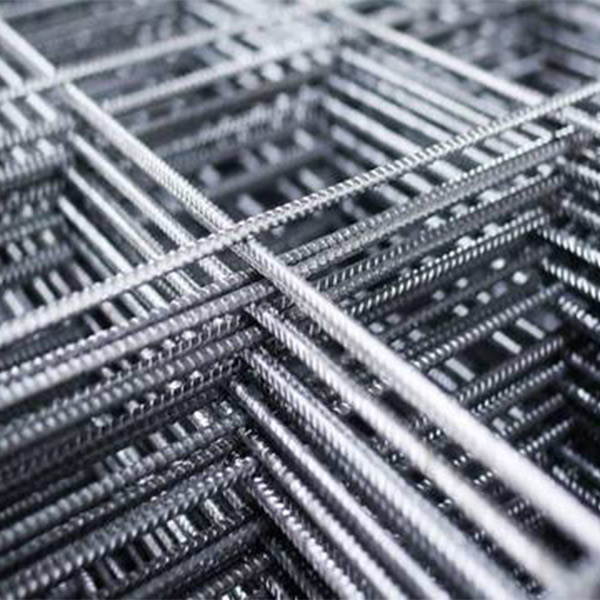

The importance of reinforcement materials in manufacturing processes cannot be understated, especially in sectors where durability and performance are paramount. Among the prominent choices in the industry are the OEM SL series, which includes models SL52, SL62, SL72, and SL82. These models are designed to enhance structural integrity and reliability across various applications.

Understanding OEM SL Series Reinforcement SL52, SL62, SL72, SL82

As we progress to the SL62, the reinforcement capabilities expand, making it suitable for medium-scale applications. This model balances weight and strength more effectively, providing better performance in environments that experience moderate stress and strain. The SL62 is often chosen for its versatility, finding applications in automotive and aerospace industries where both performance and reliability are crucial.

oem sl52 sl62 sl72 sl82 reinforcement

Further up the scale, we arrive at the SL72. This model is engineered for heavier-duty applications, providing substantial reinforcement for components subjected to increased loads and pressure. The SL72’s robust design and materials make it a go-to choice for industries like construction and heavy machinery, where the demand for durability is essential.

Finally, the SL82 represents the pinnacle of the SL series, providing unparalleled reinforcement for the most demanding applications. This model is crafted for high-performance environments, ensuring that even in the harshest conditions, structural integrity is never compromised. Industries that require extreme resilience often rely on the SL82, recognizing its capability to enhance safety and product longevity.

In conclusion, the OEM SL series, encompassing SL52, SL62, SL72, and SL82, illustrates the diverse reinforcement solutions available in manufacturing today. Each model caters to specific needs, ensuring that engineers and manufacturers can select the most appropriate option for their unique applications. By leveraging these advanced reinforcement technologies, industries can enhance product performance, safety, and longevity, ultimately leading to greater efficiency and success in their operations. The evolving landscape of manufacturing continues to embrace such innovations, pushing the boundaries of what is possible in material science and engineering.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025