Sep . 02, 2024 08:40 Back to list

OEM Reinforcing Mesh A395 - High Strength Steel Mesh for Construction

Understanding OEM Reinforcing Mesh A395

In the construction industry, the need for reliable and high-quality materials is paramount. One such material that has gained significant attention is the OEM reinforcing mesh A395. This advanced product is engineered to enhance structural integrity in various applications, from concrete slabs to reinforced walls. In this article, we will explore the characteristics, advantages, and applications of the OEM reinforcing mesh A395.

What is OEM Reinforcing Mesh A395?

OEM reinforcing mesh A395 is a specific type of steel mesh designed for reinforcement in construction projects. The term OEM refers to Original Equipment Manufacturer, indicating that the product meets rigorous industry standards and specifications. The A395 designation typically points to the mesh's specifications, including its mesh size, wire diameter, and tensile strength. This type of reinforcing mesh is primarily used to improve the tensile strength of concrete, prevent cracking, and enhance the overall durability of structures.

Key Characteristics

1. Material Composition OEM reinforcing mesh A395 is made from high-grade steel, ensuring superior strength and durability. The steel is often coated to provide resistance against corrosion, which extends the lifespan of the mesh when embedded in concrete.

2. Mesh Design The mesh is crafted in various configurations, commonly in sheets or rolls, allowing for versatility in usage. The specific design, including the spacing of the wires, is tailored to cater to different load-bearing requirements.

3. Customizable As an OEM product, the reinforcing mesh A395 can be customized to satisfy specific project needs. This includes adjustments to dimensions, wire thickness, and mesh size according to the engineering requirements of the project.

Advantages of Using OEM Reinforcing Mesh A395

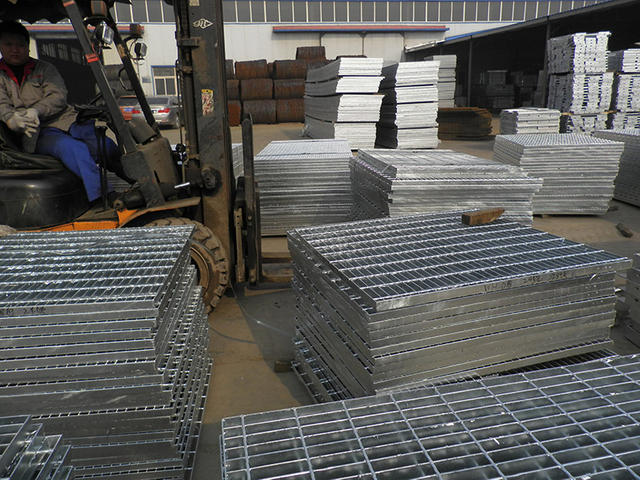

oem reinforcing mesh a395

1. Enhanced Strength One of the primary benefits of using A395 mesh is its ability to provide significant tensile strength to concrete structures. This added strength helps to withstand various stresses, including bending, stretching, and shear forces.

2. Crack Prevention Concrete is known for its tendency to crack under stress. The strategic placement of reinforcing mesh A395 within the concrete mix helps to distribute stress evenly, thereby minimizing the risk of cracks and extending the lifespan of structures.

3. Cost-Effective Utilizing reinforcing mesh can be a cost-effective solution in construction. By enhancing durability and reducing the need for frequent repairs or reinforcement, it leads to long-term savings for project developers.

4. Ease of Installation The mesh is relatively easy to install, making it a convenient option for construction workers. Its lightweight nature and flexible design allow for quick implementation, reducing labor time and costs.

Applications

OEM reinforcing mesh A395 is suitable for a wide range of applications, including but not limited to

- Road Construction Enhancing the strength of asphalt or concrete road surfaces. - Foundation Work Providing support for building foundations to prevent settling or shifting. - Flooring Systems Strengthening slabs in residential and commercial properties. - Retaining Walls Offering additional support and stability for earth retention systems.

Conclusion

In summary, OEM reinforcing mesh A395 is an invaluable component in modern construction, providing essential support and durability to structures. Its customizable features, combined with its ability to prevent cracks and enhance strength, make it a preferred choice among builders and engineers. Whether used in roads, foundations, or flooring, the A395 mesh plays a critical role in ensuring that structures stand the test of time. As the construction industry continues to evolve, products like the OEM reinforcing mesh A395 will remain at the forefront of innovative building solutions.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025