Aug . 21, 2024 15:40 Back to list

OEM Industrial Welded Wire Mesh Solutions for Various Applications

The Importance of OEM Welded Wire Mesh for Industry

In the manufacturing and construction industries, the materials used play a crucial role in determining the quality, durability, and effectiveness of the final product. One such material that has gained significant traction in various sectors is OEM (Original Equipment Manufacturer) welded wire mesh. This versatile material has found its place in a myriad of applications, from safety barriers to reinforcement in structures. This article delves into the significance of OEM welded wire mesh for the industrial sector.

What is OEM Welded Wire Mesh?

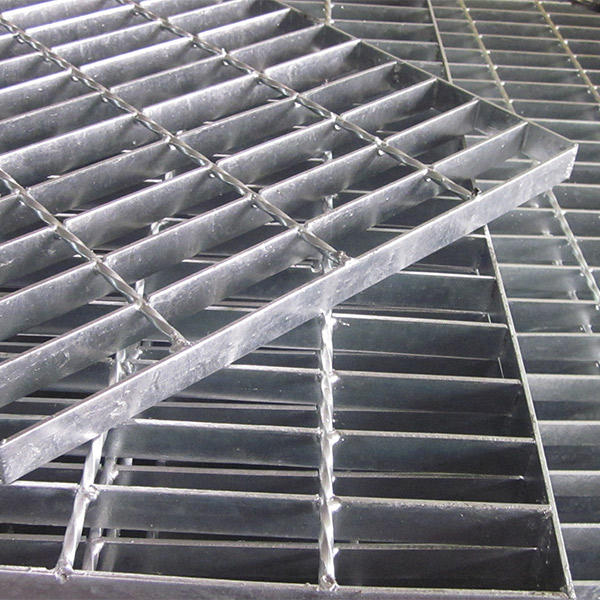

OEM welded wire mesh refers to wire mesh products that are specifically manufactured according to a client's specifications. This means that the wire mesh is tailor-made to meet the unique needs and standards of different industries, ensuring that the finished product aligns with the particular requirements of the OEM. Typically composed of high-strength steel wires that are welded together at intersections, this type of mesh provides enhanced strength and stability compared to other forms of wire mesh.

Applications in Various Industries

1. Construction Industry One of the primary applications of welded wire mesh is in the construction sector, where it is used for concrete reinforcement. The mesh provides support for concrete slabs, walls, and pavements, preventing cracking and increasing durability. Its customizable nature allows contractors to use specific sizes and gauges, ensuring that the mesh meets the structural integrity requirements of their projects.

2. Agriculture OEM welded wire mesh is widely utilized in agricultural settings for fencing, animal enclosures, and as support structures in plant growth. The sturdy design gates and barriers ensure that livestock is kept safe, while also allowing adequate ventilation and visibility.

3. Manufacturing and Industrial Applications Many industries use welded wire mesh for various applications such as shelving, machine guards, and walkways. The welded construction ensures reliability and safety in high-demand environments, reducing the risk of equipment failures or accidents.

oem welded wire mesh for industry

4. Mining and Resource Extraction In mining operations, welded wire mesh can be used for reinforcing slopes, preventing erosion, and ensuring stability in tunnels and mine shafts. The strong construction of the mesh is paramount in maintaining safe working conditions in such hazardous environments.

Advantages of OEM Welded Wire Mesh

1. Customization The most significant advantage of OEM welded wire mesh is its tailor-made nature. Manufacturers can specify the dimensions, wire gauge, and treatment (such as galvanization) to suit specific operational needs. This level of customization helps optimize performance and durability.

2. Durability and Strength Welded wire mesh is well-known for its strength. The welding process creates a robust grid that can withstand heavy loads and various environmental conditions, making it an ideal choice for a wide range of uses.

3. Cost-effectiveness Although the initial investment may be higher than other types of mesh, the longevity and low maintenance costs associated with OEM welded wire mesh can lead to substantial savings in the long run.

4. Enhanced Safety In industrial environments where safety is paramount, welded wire mesh provides an added layer of security. It can be used to create barriers and enclosures that protect workers from hazardous machinery and operations.

Conclusion

The significance of OEM welded wire mesh in the industrial sector cannot be overstated. Its versatility, strength, and customizability make it an essential component across various industries, from construction to agriculture. By providing tailored solutions that meet specific needs, OEM welded wire mesh not only enhances the quality of products but also contributes significantly to operational safety and efficiency. As industries continue to evolve, the demand for specialized materials like welded wire mesh will undoubtedly grow, solidifying its place as a cornerstone of modern manufacturing and construction.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025