Sep . 16, 2024 00:03 Back to list

OEM Galvanized Metal Wire for Construction | Durable & Reliable Solutions

The Importance of OEM Galvanized Metal Wire for Construction

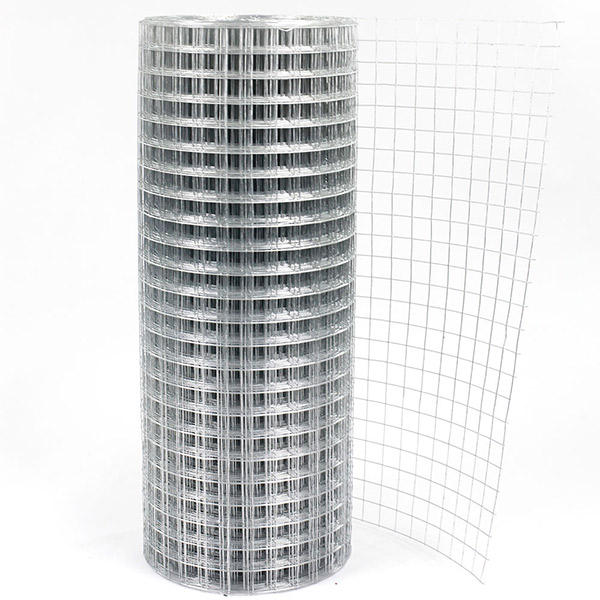

In the world of construction, choosing the right materials is critical to ensuring the integrity and longevity of any project. One material that has gained significant popularity is OEM galvanized metal wire. This specialized wire is coated with a layer of zinc, which provides exceptional resistance to corrosion and rust, making it an ideal choice for various construction applications.

Galvanized metal wire is widely utilized in the construction industry for its strength, versatility, and durability. Its primary function often includes reinforcement in concrete, creating sturdy frameworks for buildings, fences, and other structures. The galvanization process not only enhances the wire's mechanical properties but also prolongs its lifespan, reducing maintenance costs and the need for frequent replacements. This is particularly important in construction, where longevity and reliability are paramount.

OEM (Original Equipment Manufacturer) galvanized metal wire refers to wire that is produced according to specific standards and requirements set by companies that incorporate these materials into their projects. This means that the wire has been manufactured with a focus on quality and consistency, ensuring that it meets the exact needs of the construction industry. Using OEM products can offer additional peace of mind for contractors and builders, as they are assured of the material's performance and compliance with industry standards.

oem galvanized metal wire for construction

The applications of OEM galvanized metal wire in construction are vast. It is commonly used for tying rebar in concrete slabs, creating wire meshes for structural support, and even in temporarily securing materials on construction sites. The adaptability of this wire allows it to be employed in various environments, whether exposed to harsh weather conditions or used in indoor applications.

Furthermore, the economic benefits of using OEM galvanized metal wire cannot be overlooked. While the initial investment may be slightly higher than non-galvanized alternatives, the longevity and low maintenance requirements lead to cost savings over time. Reduced need for replacements and repairs means that projects can stay on budget and on schedule.

In conclusion, OEM galvanized metal wire plays a crucial role in the construction industry, offering immense benefits through its durability, strength, and cost-effectiveness. As construction projects continue to evolve and demand high-quality materials, galvanized metal wire stands out as a reliable choice for builders and contractors alike. Investing in this material not only enhances the structural integrity of construction projects but also contributes to the overall sustainability of the building process.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025