Jun . 25, 2024 22:23 Back to list

OEM Built Welded Mesh Construction Robust and Custom Solutions

The Evolution of OEM Building Welded Mesh A Pioneering Solution for Construction Needs

In the realm of construction, one groundbreaking innovation that has revolutionized the industry is the emergence of OEM (Original Equipment Manufacturer) building welded mesh. This specialized product, characterized by its precision engineering and high-quality manufacturing, has transformed the way structures are fortified and reinforced.

At its core, an OEM building welded mesh is a custom-designed, welded wire fabric that meets stringent industry standards. The process begins with meticulous research and development, where engineers collaborate closely with architects to understand the specific requirements of each project. This ensures that the final product not only complies with safety regulations but also enhances the aesthetics and functionality of the built environment.

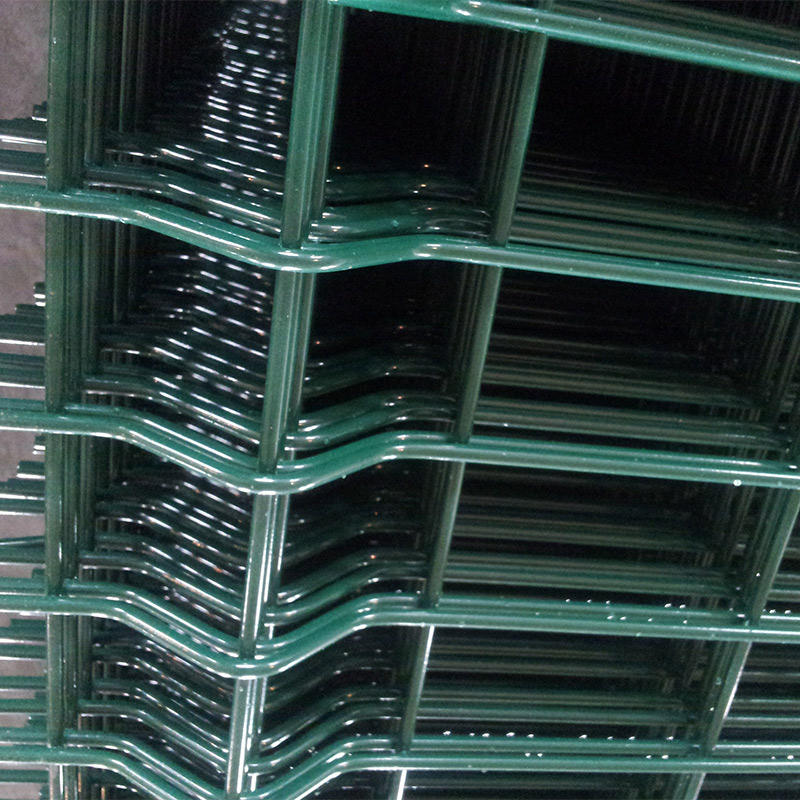

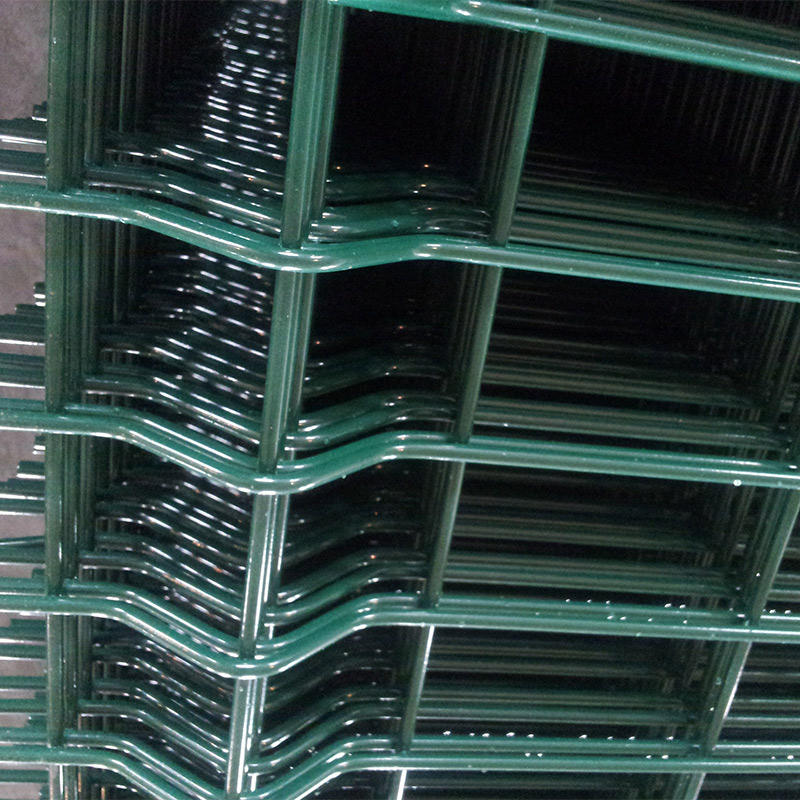

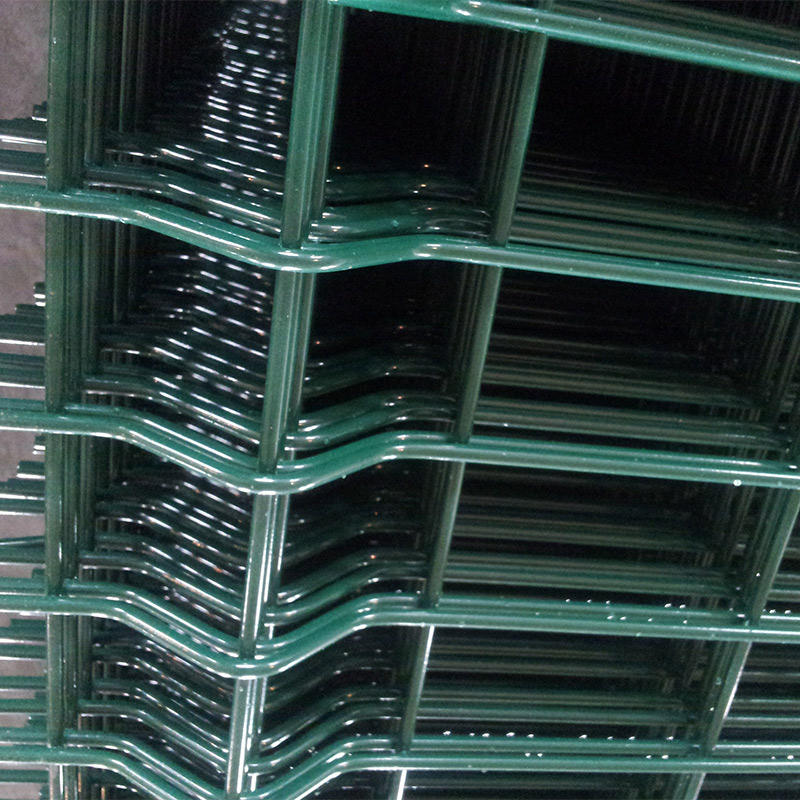

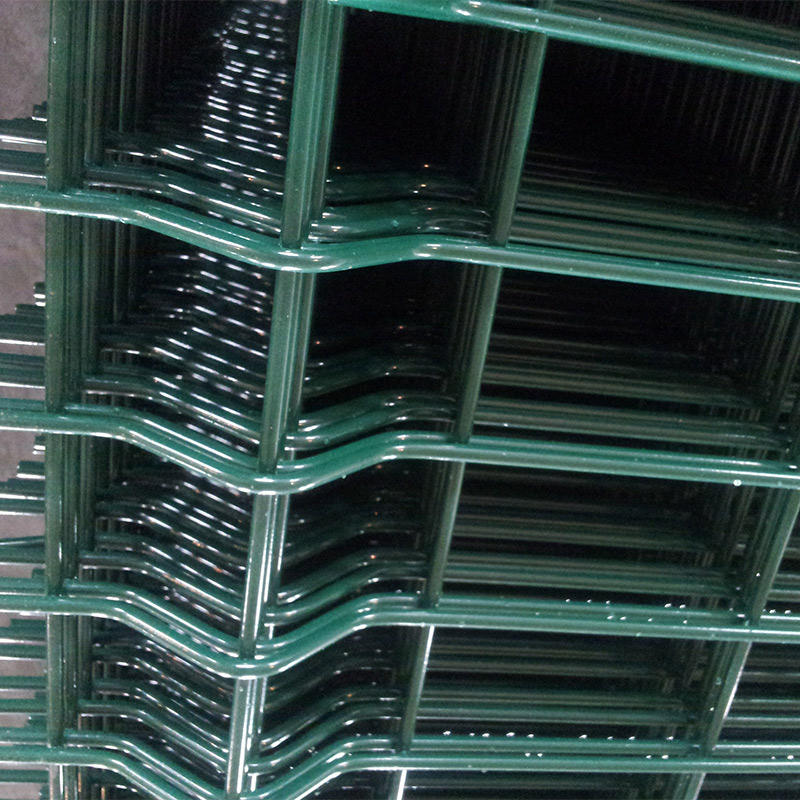

The manufacturing process involves the skilled fusion of wire strands, forming a robust and durable structure that can withstand the rigors of time and external forces. Each weld is carefully executed, ensuring a seamless bond that prevents potential weaknesses or failures. This attention to detail results in a product with exceptional strength-to-weight ratio, making it an ideal choice for load-bearing applications in both commercial and residential buildings.

One of the key advantages of OEM building welded mesh is its versatility. It can be easily tailored to fit various architectural styles and construction techniques, from traditional masonry to modern steel structures. Its adaptability allows architects to incorporate it seamlessly into their designs, creating visually appealing and structurally sound facades Its adaptability allows architects to incorporate it seamlessly into their designs, creating visually appealing and structurally sound facades Its adaptability allows architects to incorporate it seamlessly into their designs, creating visually appealing and structurally sound facades Its adaptability allows architects to incorporate it seamlessly into their designs, creating visually appealing and structurally sound facades

Its adaptability allows architects to incorporate it seamlessly into their designs, creating visually appealing and structurally sound facades Its adaptability allows architects to incorporate it seamlessly into their designs, creating visually appealing and structurally sound facades oem building welded mesh.

Moreover, the use of welded mesh in construction offers numerous environmental benefits. It promotes energy efficiency by enhancing insulation, reducing heat loss, and minimizing air infiltration. Additionally, its recyclable nature aligns with sustainable building practices, contributing to a greener future.

In recent years, the OEM building welded mesh market has experienced significant growth, driven by its proven performance, cost-effectiveness, and the increasing demand for smart and sustainable construction solutions. As technology advances, manufacturers continue to refine their processes, incorporating digital tools to streamline production and enhance quality control.

In conclusion, the OEM building welded mesh stands as a testament to the power of innovation in the construction industry. Its ability to meet the unique demands of modern architecture while maintaining structural integrity and environmental responsibility makes it a game-changer. As the industry continues to evolve, we can expect this innovative material to play an even more pivotal role in shaping the future of sustainable, efficient, and resilient buildings.

oem building welded mesh.

Moreover, the use of welded mesh in construction offers numerous environmental benefits. It promotes energy efficiency by enhancing insulation, reducing heat loss, and minimizing air infiltration. Additionally, its recyclable nature aligns with sustainable building practices, contributing to a greener future.

In recent years, the OEM building welded mesh market has experienced significant growth, driven by its proven performance, cost-effectiveness, and the increasing demand for smart and sustainable construction solutions. As technology advances, manufacturers continue to refine their processes, incorporating digital tools to streamline production and enhance quality control.

In conclusion, the OEM building welded mesh stands as a testament to the power of innovation in the construction industry. Its ability to meet the unique demands of modern architecture while maintaining structural integrity and environmental responsibility makes it a game-changer. As the industry continues to evolve, we can expect this innovative material to play an even more pivotal role in shaping the future of sustainable, efficient, and resilient buildings.

Its adaptability allows architects to incorporate it seamlessly into their designs, creating visually appealing and structurally sound facades Its adaptability allows architects to incorporate it seamlessly into their designs, creating visually appealing and structurally sound facades

Its adaptability allows architects to incorporate it seamlessly into their designs, creating visually appealing and structurally sound facades Its adaptability allows architects to incorporate it seamlessly into their designs, creating visually appealing and structurally sound facades oem building welded mesh.

Moreover, the use of welded mesh in construction offers numerous environmental benefits. It promotes energy efficiency by enhancing insulation, reducing heat loss, and minimizing air infiltration. Additionally, its recyclable nature aligns with sustainable building practices, contributing to a greener future.

In recent years, the OEM building welded mesh market has experienced significant growth, driven by its proven performance, cost-effectiveness, and the increasing demand for smart and sustainable construction solutions. As technology advances, manufacturers continue to refine their processes, incorporating digital tools to streamline production and enhance quality control.

In conclusion, the OEM building welded mesh stands as a testament to the power of innovation in the construction industry. Its ability to meet the unique demands of modern architecture while maintaining structural integrity and environmental responsibility makes it a game-changer. As the industry continues to evolve, we can expect this innovative material to play an even more pivotal role in shaping the future of sustainable, efficient, and resilient buildings.

oem building welded mesh.

Moreover, the use of welded mesh in construction offers numerous environmental benefits. It promotes energy efficiency by enhancing insulation, reducing heat loss, and minimizing air infiltration. Additionally, its recyclable nature aligns with sustainable building practices, contributing to a greener future.

In recent years, the OEM building welded mesh market has experienced significant growth, driven by its proven performance, cost-effectiveness, and the increasing demand for smart and sustainable construction solutions. As technology advances, manufacturers continue to refine their processes, incorporating digital tools to streamline production and enhance quality control.

In conclusion, the OEM building welded mesh stands as a testament to the power of innovation in the construction industry. Its ability to meet the unique demands of modern architecture while maintaining structural integrity and environmental responsibility makes it a game-changer. As the industry continues to evolve, we can expect this innovative material to play an even more pivotal role in shaping the future of sustainable, efficient, and resilient buildings. Latest news

-

12mm Stainless Steel Wire Mesh for Industrial & Commercial Use Top Quality Factories & Manufacturers

NewsJun.24,2025

-

Black Annealed Wire Specification - High Quality & Custom Options from Leading Factories, Suppliers, Manufacturers

NewsJun.10,2025

-

High-Quality 18 Gauge Black Steel Wire Reliable Factories & Suppliers

NewsJun.10,2025

-

Chain Link Fence Gates - Durable & Secure Access Solutions

NewsJun.10,2025

-

Premium Cold Rolled Steel Bar Supplier High Strength & Precision

NewsJun.10,2025

-

Galvanized Wire Brick Force Mesh - Corrosion Resistant

NewsJun.09,2025