Oct . 20, 2024 17:30 Back to list

mesh high strength manufacturer

The Rise of High Strength Mesh Manufacturing

In the ever-evolving landscape of production, the demand for durable and reliable materials has pushed many industries to seek innovative manufacturing solutions. One such solution is high-strength mesh, which has gained prominence in various sectors, from construction to agriculture. This article explores the significance of high-strength mesh manufacturing, its applications, and the technological advancements that have fueled its growth.

Understanding High Strength Mesh

High-strength mesh is constructed from various materials, including stainless steel, galvanized steel, and synthetic polymers. Its defining characteristic is its exceptional tensile strength, making it resistant to deformation under load. This mesh is designed to withstand substantial pressure and environmental factors, which plays a crucial role in its applications across different industries.

Applications of High Strength Mesh

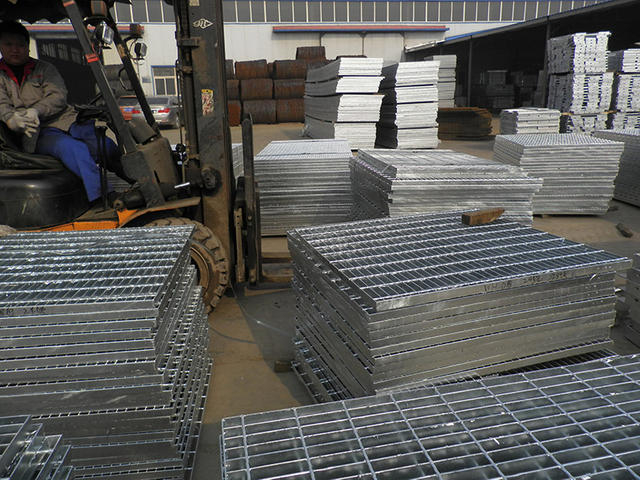

1. Construction and Civil Engineering In the construction industry, high-strength mesh is utilized for concrete reinforcement. It helps to distribute loads evenly and improves the structural integrity of buildings and bridges. Mesh is commonly used in slabs, walls, and pavements, ensuring durability and longevity.

2. Agriculture Farmers have started to appreciate the advantages of high-strength mesh for protective enclosures, fencing, and trellises. The mesh supports robust plant growth while protecting crops from pests and harsh weather conditions. Its high tensile strength ensures the structures remain effective over time, even in challenging environments.

3. Mining and Industrial Applications High-strength mesh is crucial in mining operations, serving as support systems in tunnels and preventing rock falls. In industrial settings, the mesh provides safety barriers and sieves, enhancing operational efficiency and risk management.

mesh high strength manufacturer

4. Automotive and Aerospace In the automotive and aerospace industries, high-strength mesh is used in components that require lightweight yet strong materials. This application reduces vehicle weight, leading to improved fuel efficiency while maintaining safety and performance standards.

Technological Innovations in Manufacturing

The production of high-strength mesh has benefited significantly from advancements in manufacturing technologies. Modern techniques such as 3D printing, precision welding, and automated weaving have enhanced the quality and efficiency of mesh production.

1. Material Advances The development of high-performance alloys and composites has expanded the functionality and durability of high-strength mesh products. These materials can withstand extreme environmental conditions, including high temperatures and corrosive substances.

2. Customized Solutions As industries become more specialized, the demand for customized solutions has increased. Manufacturers have adapted by offering tailored mesh products that meet specific requirements regarding size, shape, and strength. This flexibility allows businesses to optimize their operations and achieve better results.

3. Sustainability Initiatives With an increasing focus on sustainable practices, many manufacturers are incorporating eco-friendly processes in mesh production. This includes recycling materials and reducing waste, aligning with global efforts to promote sustainability in manufacturing.

Conclusion

High-strength mesh manufacturing is a testament to how modern technology and innovative practices can enhance material capabilities across various sectors. With its wide range of applications and the continuous development of production techniques, high-strength mesh is set to play an even more significant role in the future. As industries strive for greater efficiency, safety, and sustainability, the importance of high-strength mesh will undoubtedly continue to grow. The advancements in this field not only promise enhanced performance in applications but also contribute to the overall innovation landscape, paving the way for new opportunities and challenges in manufacturing.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025