Jun . 26, 2024 11:46 Back to list

Manufacturing Welded Mesh for Bridge Construction

Welded Mesh for Bridge Manufacturer A Revolutionary Innovation

In the world of civil engineering, the construction of bridges is a monumental task that requires meticulous planning and execution. One crucial component in this process is the welded mesh, which has become an integral part of modern bridge construction. In this article, we will explore the significance of welded mesh for bridge manufacturers and how it has revolutionized the industry.

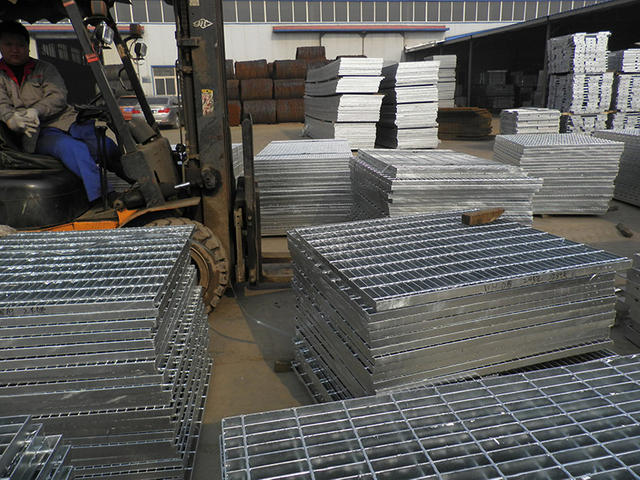

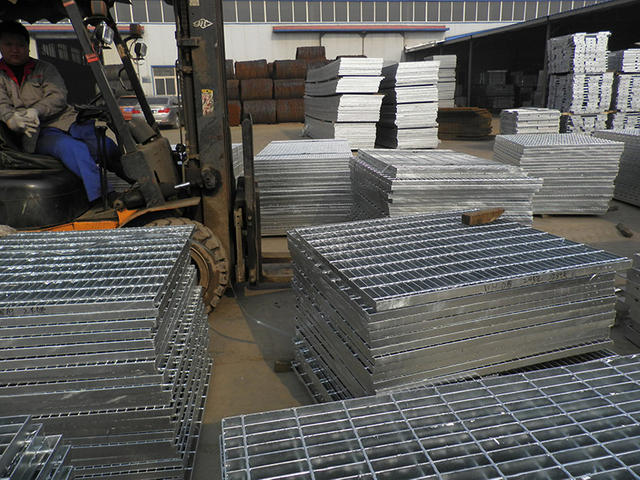

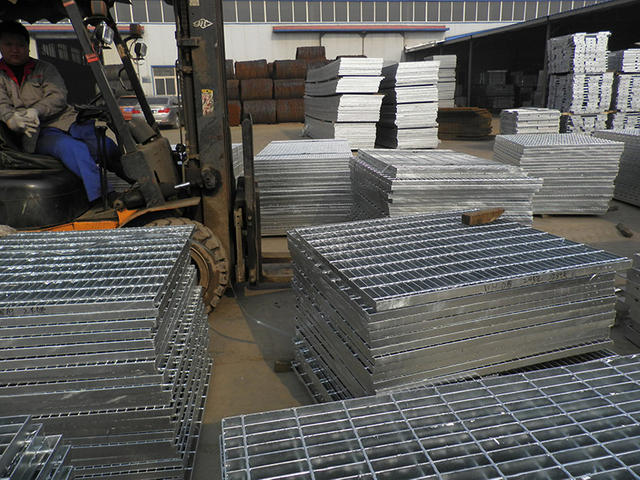

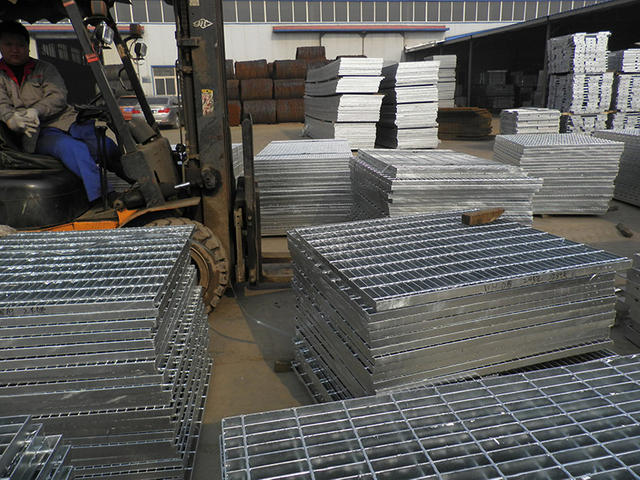

Welded mesh, also known as welded wire fabric or welded steel mesh, is a type of metal grid that is manufactured by welding the intersection points of wires in a square or rectangular pattern. This robust and durable material offers numerous benefits to bridge manufacturers, making it an essential element in their construction projects.

Firstly, welded mesh provides excellent structural support due to its high tensile strength and flexibility. It can be easily molded into various shapes and sizes, allowing engineers to design custom-made solutions for different types of bridges. Moreover, its uniform grid pattern ensures consistent load distribution, reducing the risk of structural failures and extending the lifespan of the bridge.

Secondly, welded mesh offers superior corrosion resistance compared to traditional materials like wood or concrete. This feature makes it ideal for use in harsh environments where exposure to moisture, saltwater, or chemical spills is common. By using welded mesh, bridge manufacturers can ensure long-term durability and reduce maintenance costs associated with frequent repairs or replacements By using welded mesh, bridge manufacturers can ensure long-term durability and reduce maintenance costs associated with frequent repairs or replacements By using welded mesh, bridge manufacturers can ensure long-term durability and reduce maintenance costs associated with frequent repairs or replacements By using welded mesh, bridge manufacturers can ensure long-term durability and reduce maintenance costs associated with frequent repairs or replacements

By using welded mesh, bridge manufacturers can ensure long-term durability and reduce maintenance costs associated with frequent repairs or replacements By using welded mesh, bridge manufacturers can ensure long-term durability and reduce maintenance costs associated with frequent repairs or replacements welded mesh for bridge manufacturer.

Thirdly, welded mesh promotes faster and more efficient construction processes. Its lightweight nature allows for easier handling during transportation and installation, reducing labor costs and minimizing project delays. Additionally, its pre-fabricated nature eliminates the need for on-site cutting or shaping, further streamlining the construction process and ensuring consistent quality across all sections of the bridge.

Furthermore, welded mesh contributes to environmental sustainability by promoting recyclability. At the end of its service life, welded mesh can be recycled and repurposed for other applications, reducing waste and conserving natural resources. This aspect aligns well with the growing trend towards sustainable infrastructure development and green building practices.

In conclusion, welded mesh has emerged as a game-changer for bridge manufacturers worldwide. Its exceptional strength, durability, corrosion resistance, ease of installation, and recyclability make it an indispensable material for modern bridge construction projects. As technology continues to advance and innovation thrives in the field of civil engineering, we can expect even more advancements in the use of welded mesh for bridge manufacturing in the future.

welded mesh for bridge manufacturer.

Thirdly, welded mesh promotes faster and more efficient construction processes. Its lightweight nature allows for easier handling during transportation and installation, reducing labor costs and minimizing project delays. Additionally, its pre-fabricated nature eliminates the need for on-site cutting or shaping, further streamlining the construction process and ensuring consistent quality across all sections of the bridge.

Furthermore, welded mesh contributes to environmental sustainability by promoting recyclability. At the end of its service life, welded mesh can be recycled and repurposed for other applications, reducing waste and conserving natural resources. This aspect aligns well with the growing trend towards sustainable infrastructure development and green building practices.

In conclusion, welded mesh has emerged as a game-changer for bridge manufacturers worldwide. Its exceptional strength, durability, corrosion resistance, ease of installation, and recyclability make it an indispensable material for modern bridge construction projects. As technology continues to advance and innovation thrives in the field of civil engineering, we can expect even more advancements in the use of welded mesh for bridge manufacturing in the future.

By using welded mesh, bridge manufacturers can ensure long-term durability and reduce maintenance costs associated with frequent repairs or replacements By using welded mesh, bridge manufacturers can ensure long-term durability and reduce maintenance costs associated with frequent repairs or replacements

By using welded mesh, bridge manufacturers can ensure long-term durability and reduce maintenance costs associated with frequent repairs or replacements By using welded mesh, bridge manufacturers can ensure long-term durability and reduce maintenance costs associated with frequent repairs or replacements welded mesh for bridge manufacturer.

Thirdly, welded mesh promotes faster and more efficient construction processes. Its lightweight nature allows for easier handling during transportation and installation, reducing labor costs and minimizing project delays. Additionally, its pre-fabricated nature eliminates the need for on-site cutting or shaping, further streamlining the construction process and ensuring consistent quality across all sections of the bridge.

Furthermore, welded mesh contributes to environmental sustainability by promoting recyclability. At the end of its service life, welded mesh can be recycled and repurposed for other applications, reducing waste and conserving natural resources. This aspect aligns well with the growing trend towards sustainable infrastructure development and green building practices.

In conclusion, welded mesh has emerged as a game-changer for bridge manufacturers worldwide. Its exceptional strength, durability, corrosion resistance, ease of installation, and recyclability make it an indispensable material for modern bridge construction projects. As technology continues to advance and innovation thrives in the field of civil engineering, we can expect even more advancements in the use of welded mesh for bridge manufacturing in the future.

welded mesh for bridge manufacturer.

Thirdly, welded mesh promotes faster and more efficient construction processes. Its lightweight nature allows for easier handling during transportation and installation, reducing labor costs and minimizing project delays. Additionally, its pre-fabricated nature eliminates the need for on-site cutting or shaping, further streamlining the construction process and ensuring consistent quality across all sections of the bridge.

Furthermore, welded mesh contributes to environmental sustainability by promoting recyclability. At the end of its service life, welded mesh can be recycled and repurposed for other applications, reducing waste and conserving natural resources. This aspect aligns well with the growing trend towards sustainable infrastructure development and green building practices.

In conclusion, welded mesh has emerged as a game-changer for bridge manufacturers worldwide. Its exceptional strength, durability, corrosion resistance, ease of installation, and recyclability make it an indispensable material for modern bridge construction projects. As technology continues to advance and innovation thrives in the field of civil engineering, we can expect even more advancements in the use of welded mesh for bridge manufacturing in the future. Latest news

-

Glass Jar with Wooden Screw Lid-Anping County Puersen Hardware Wire Mesh Products Co.,Ltd|Thermal Resistance&Eco-Friendly

NewsAug.17,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd|High Borosilicate Glass&Eco-Friendly Design

NewsAug.17,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Thermal Resistance Eco-Friendly Airtight Seal

NewsAug.17,2025

-

Glass Jar with Wooden Screw Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.17,2025

-

Diamond Steel Grating Factory: Leading Manufacturer & Supplier

NewsAug.17,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Premium Eco-Friendly Storage Solution|Anping County Puersen Hardware Wire Mesh Products Co.,Ltd

NewsAug.16,2025