Aug . 14, 2024 06:40 Back to list

Manufacturers of Welded Wire Mesh for Concrete Reinforcement Solutions and Applications

The Role of Concrete Reinforcing Welded Wire Mesh Factories in Modern Construction

Concrete is one of the most widely used construction materials in the world, known for its durability, strength, and versatility. To enhance its load-bearing capabilities, engineers and constructors often employ various reinforcing techniques. One of the most effective methods is the use of welded wire mesh, which provides supplementary strength to concrete structures. This article explores the significance of concrete reinforcing welded wire mesh factories in modern construction, highlighting their production processes, applications, and impact on the industry.

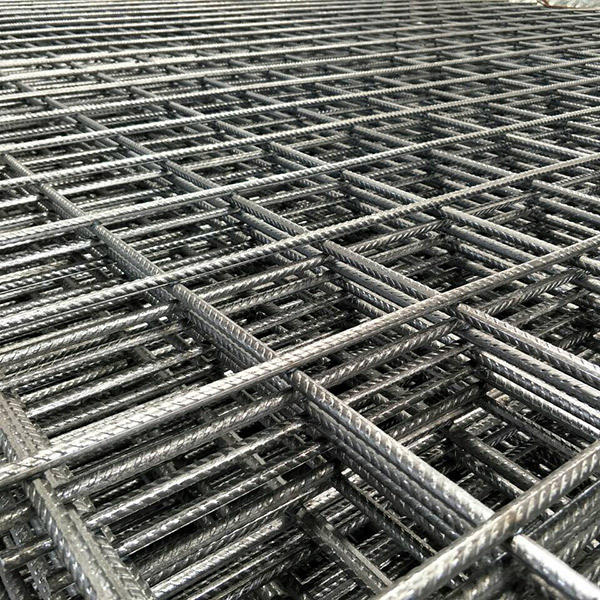

Understanding Welded Wire Mesh

Welded wire mesh consists of a grid of steel wires that are welded together at their intersections, forming a robust and stable framework. This mesh is embedded within the concrete during the pouring process, providing reinforcement against tensile forces and helping to resist cracking and deformation over time. Its design can be customized based on specific load requirements, making it an essential component for various construction projects, from residential buildings to bridges and pavements.

The Production Process

Concrete reinforcing welded wire mesh factories utilize sophisticated machinery and techniques to ensure that the wire mesh produced meets strict quality standards. The process begins with the selection of high-quality steel wires, often sourced from reputable suppliers. These wires are then drawn into the desired thickness and coated for enhanced corrosion resistance. Once the wires are prepared, they are arranged in a grid formation and welded at each intersection using automated welding machines.

These factories implement rigorous quality control measures at every stage of production

. By adhering to industrial standards such as ASTM (American Society for Testing and Materials) and ISO certifications, manufacturers ensure that the welded wire mesh delivered to construction sites can withstand the demands of various structural applications.Applications in Construction

concrete reinforcing welded wire mesh factories

Concrete reinforcing welded wire mesh is widely used in several construction applications. Its primary role is within concrete slabs, providing support for floors in residential and commercial buildings. In addition, it is extensively used in precast concrete products, such as walls and ceilings, where added strength and stability are required. Furthermore, it plays a crucial role in infrastructure projects, such as highways and bridges, where it helps to distribute loads and enhance durability.

The versatility of welded wire mesh extends to landscaping and agricultural sectors, where it can be employed in fencing, erosion control, and soil stabilization. This adaptability allows manufacturers to cater to a diverse range of industries beyond traditional construction.

Economic and Environmental Impact

The proliferation of concrete reinforcing welded wire mesh factories contributes significantly to the economy by providing jobs and supporting local industries. Furthermore, the use of welded wire mesh in construction can lead to cost savings. Its enhanced strength allows for the use of thinner slabs of concrete, reducing material costs while maintaining structural integrity.

From an environmental perspective, welded wire mesh can also promote sustainability. By optimizing concrete usage and improving the longevity of structures, it ultimately reduces the need for repairs and replications, resulting in lower consumption of resources over time.

Conclusion

Concrete reinforcing welded wire mesh factories play an indispensable role in the construction industry. Through advanced production techniques and stringent quality controls, these factories provide essential materials that enhance the strength and performance of concrete structures. As construction continues to evolve, the importance of welded wire mesh will only grow, ensuring that buildings and infrastructure can withstand the test of time while promoting economic and environmental sustainability. In an era where safety and durability are paramount, the contribution of welded wire mesh cannot be overstated, solidifying its position as a cornerstone of modern construction practices.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025