Jul . 29, 2024 23:12 Back to list

Manufacturers of Twisted Bars for Customized Welding Solutions in Grating Applications

The Importance of Twisted Bars in Grating Welding A Manufacturing Perspective

In the realm of construction and industrial applications, the significance of durable and reliable materials cannot be overstated. Among the various components that contribute to structural integrity, twisted bars for grating welding have emerged as essential elements in producing high-quality grates. This article delves into the importance of twisted bars, their manufacturing process, and their applications in various industries.

Understanding Twisted Bars

Twisted bars, commonly used in welding applications, are steel reinforcement bars that have undergone a twisting process to enhance their mechanical properties. The twisting action increases the surface area of the bar, allowing for better bonding with the surrounding concrete or welding material. These bars are not only recognized for their structural benefits but also for their reduced likelihood of slippage during the welding process, leading to stronger and more durable end products.

Manufacturing Twisted Bars

The manufacturing of twisted bars involves several stages to ensure they meet the required specifications for strength and durability. The process typically begins with the selection of high-quality raw materials, which often include carbon steel due to its superior strength-to-weight ratio.

1. Rolling The raw steel is first heated and rolled into long, straight bars. This initial stage is crucial as it determines the basic dimensions and mechanical properties of the bars.

2. Twisting Once the bars are formed, they undergo a twisting process. This step may involve various methods, including rotary or manual twisting, depending on the desired end properties. The degree of twist is carefully controlled to achieve optimal performance characteristics, such as tensile strength and ductility.

3. Cutting and Finishing After twisting, the bars are cut into specified lengths based on client requirements. Additional finishing processes—such as surface treatment, coating to prevent corrosion, and quality inspection—are conducted to ensure that the bars meet industry standards.

twisted bars for grating welding manufacturer

4. Quality Control Rigid quality control measures are implemented throughout the manufacturing process. This includes tensile testing, visual inspections, and adhesion tests to guarantee that every batch of twisted bars is capable of withstanding the rigors of real-world applications.

Applications in Various Industries

Twisted bars are versatile and find applications across numerous sectors, including construction, automotive, and aerospace.

- Construction In the construction industry, twisted bars are widely used in reinforced concrete applications. They provide added tensile strength, especially in grating systems, where the bars are welded together to form a strong, load-bearing surface capable of handling heavy traffic.

- Automotive The automotive sector also utilizes twisted bars in various components, where their strength and flexibility contribute to the overall safety and performance of vehicles.

- Aerospace In aerospace applications, where weight and strength are critical, twisted bars may be used in structural components, ensuring that the aircraft components are both lightweight and robust.

Conclusion

In summary, twisted bars play a crucial role in the manufacturing and welding of grating systems, offering enhanced strength and durability. Their unique properties, resulting from the twisting process, make them indispensable in various applications, from construction to aerospace. As industries continue to evolve, the demand for high-quality twisted bars will likely increase, underscoring the importance of manufacturers who prioritize innovation and quality in their production processes. Embracing advanced manufacturing techniques and comprehensive quality control measures will ensure that twisted bars remain at the forefront of material science, contributing significantly to the safety and durability of structures worldwide.

-

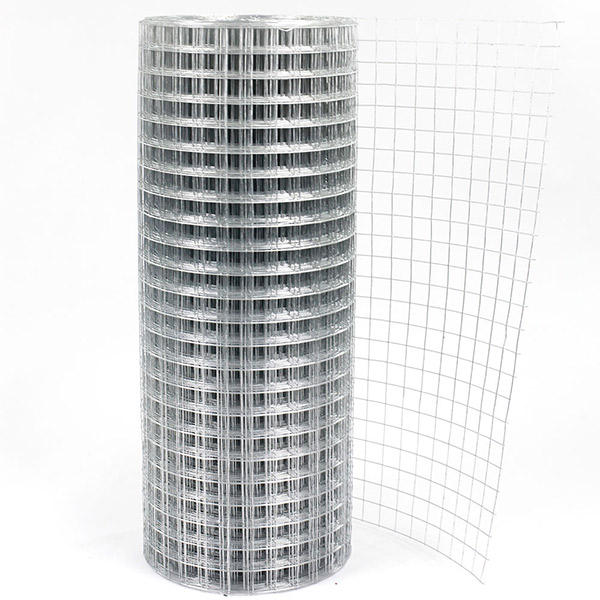

Welded Wire Mesh for Industry Factory - Anping County Puersen Hardware Wire Mesh Products Co., Ltd.

NewsAug.29,2025

-

Welded Wire Mesh for Industry Factory | Durable & Cost-Effective Solutions

NewsAug.29,2025

-

Durable Welded Wire Mesh for Industry Factory | Custom Solutions

NewsAug.27,2025

-

Durable Welded Wire Mesh for Industry Factory - High Quality

NewsAug.26,2025

-

Leading Galvanized Steel Fence Factory | Durable & Secure Fencing

NewsAug.24,2025

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025